Preparation method of composite phase combined magnesium-base unshaped refractory material applied to bottom of electric furnace

A technology of complex combination and refractory materials, applied in the field of refractory materials, can solve problems such as prolonging the life of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

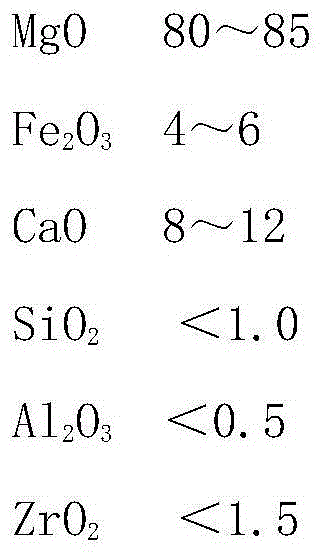

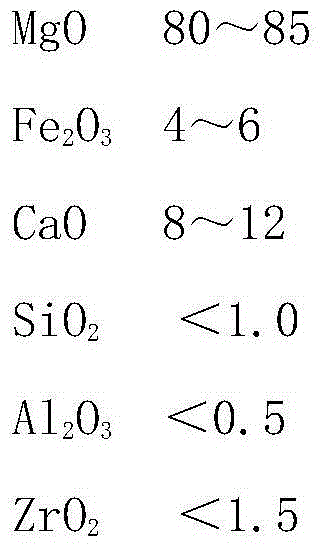

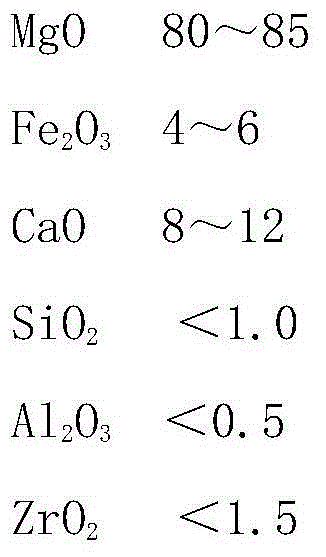

[0024] The preparation method of composite-phase combined magnesium-based amorphous refractories for the bottom of an electric furnace, the raw materials are proportioned by weight, 95 parts of synthetic balls made of dolomite powder and iron oxide powder, plus 5 parts of desiliconized zirconium; the dolomite powder MgO+ CaO≥80%, iron oxide powder Fe 2 o 3 >98%, desiliconized zirconium ZrO 2 >98.5%; specific steps are as follows:

[0025] 1) Process and grind the dolomite powder and iron oxide powder into a fine powder with a particle size of 325 mesh, proportion by weight, 105 parts of dolomite powder, 2 parts of iron oxide powder, knead the above particle size materials, press balls, dry, and fire, Make dolomite powder-iron oxide powder synthetic ball;

[0026] 2) Process and grind dolomite powder-iron oxide powder synthetic balls into fine powders with a particle size of 6-3mm, 3-1mm, and 1-0㎜, and extract 1-0㎜ fine powder from dolomite powder-iron oxide powder synthetic...

Embodiment 2

[0029] The preparation method of composite-phase combined magnesium-based amorphous refractories for the bottom of an electric furnace, the raw materials are proportioned by weight, 97 parts of synthetic balls made of dolomite powder and iron oxide powder, plus 3 parts of desiliconized zirconium; the dolomite powder MgO+ CaO≥80%, iron oxide powder Fe 2 o 3 >98%, desiliconized zirconium ZrO 2 >98.5%; specific steps are as follows:

[0030] 1) Process and grind the dolomite powder and iron oxide powder into a fine powder with a particle size of 325 mesh, proportion by weight, 110 parts of dolomite powder, 3 parts of iron oxide powder, knead the above-mentioned particle size materials, press balls, dry, and fire, Make dolomite powder-iron oxide powder synthetic ball;

[0031] 2) Process and grind dolomite powder-iron oxide powder synthetic balls into fine powders with a particle size of 6-3mm, 3-1mm, and 1-0㎜, and extract 1-0㎜ fine powder from dolomite powder-iron oxide powder...

Embodiment 3

[0034] The preparation method of complex-phase combined magnesium-based amorphous refractories for the bottom of an electric furnace, the raw materials are proportioned by weight, 99 parts of synthetic balls made of dolomite powder and iron oxide powder, plus 1 part of desiliconized zirconium; the dolomite powder MgO+ CaO≥80%, iron oxide powder Fe 2 o 3 >98%, desiliconized zirconium ZrO 2 >98.5%; specific steps are as follows:

[0035] 1) Process and grind the dolomite powder and iron oxide powder into a fine powder with a particle size of 325 mesh, proportion by weight, 115 parts of dolomite powder, 4 parts of iron oxide powder, knead the above-mentioned particle size materials, press balls, dry, and fire, Made dolomite powder-iron oxide powder synthetic ball;

[0036] 2) Process and grind dolomite powder-iron oxide powder synthetic balls into fine powders with a particle size of 6-3mm, 3-1mm, and 1-0㎜, and extract 1-0㎜ fine powder from dolomite powder-iron oxide powder sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com