Composite positive electrode material, preparation method thereof and aqueous secondary battery

A composite positive electrode material and mixture technology, applied in the field of energy storage, can solve the problems of volume shrinkage, volume expansion, poor cycle life, etc., achieve the effects of volume expansion and shrinkage reduction, increase energy density, and increase compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

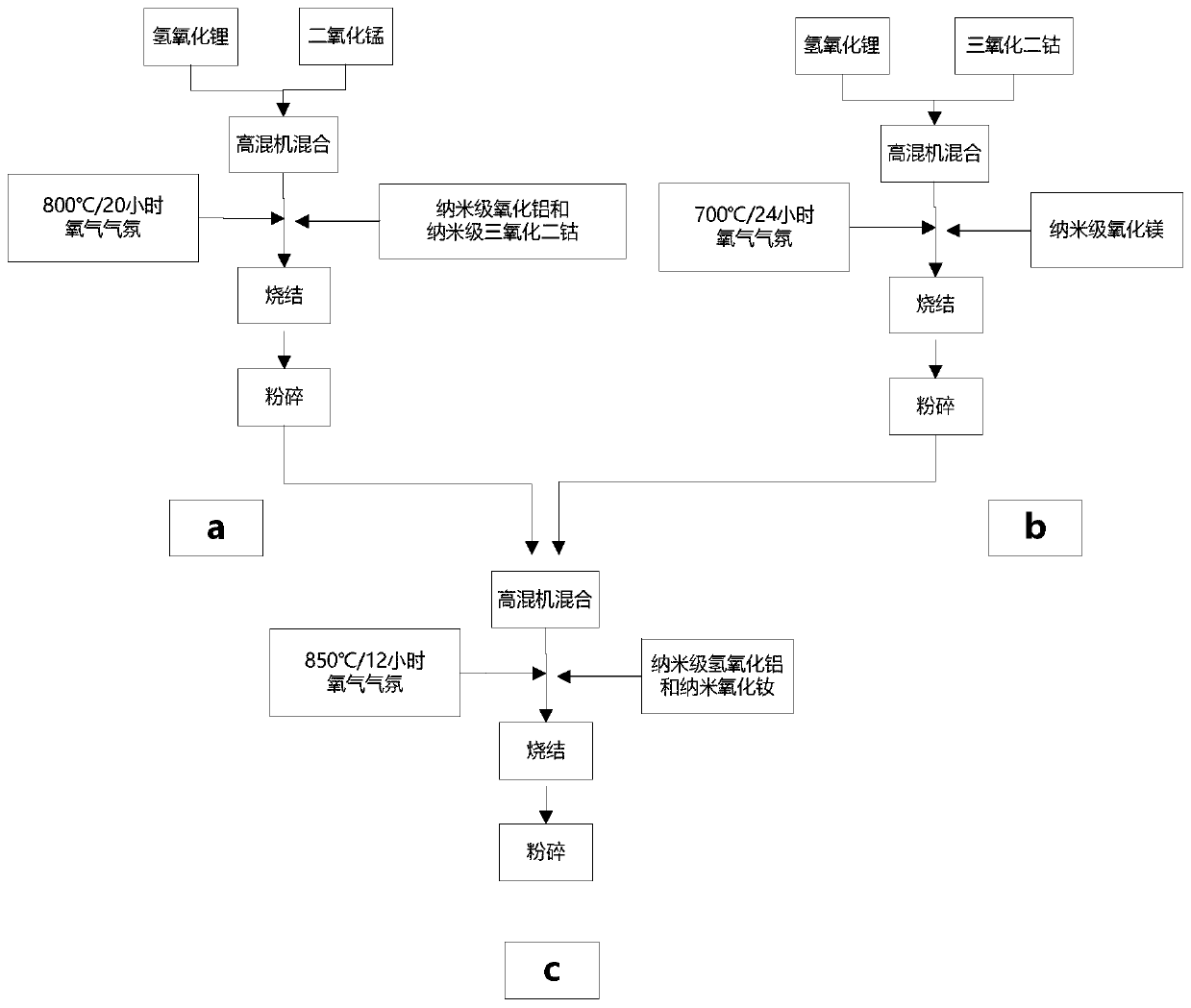

[0064] Step a): Preparation of modified lithium manganate:

[0065] Such as figure 1 As shown, lithium hydroxide and manganese dioxide are used as raw materials, with a molar ratio of Li / Mn=1.05:2.0. At the same time, 0.5% of the total mass of lithium hydroxide and manganese dioxide is added to nano-alumina and 0.5% nano Grade cobalt trioxide is mixed in a high-speed mixer for 2 hours, and then roasted in an oxygen atmosphere furnace at a temperature of 800°C for 20 hours. After the temperature is cooled down, it is pulverized to a micron level using a jet mill. The material prepared in this step is denoted as a.

[0066] Step b): Preparation of modified lithium cobalt oxide:

[0067] Lithium hydroxide and cobalt trioxide are used as raw materials, with a molar ratio of Li / Mn=1.05:1.0. At the same time, 1% of the total mass of lithium hydroxide and cobalt trioxide are added, and the materials are mixed in a high-speed mixer After 2 hours, it is calcined in an oxygen atmosphere furn...

Embodiment 2

[0070] The preparation method of the composite positive electrode material in this embodiment is the same as the preparation method of the composite positive electrode material in Example 1, except that a prepared in step a) in step c) and b prepared in step b) are in a ratio of 0.7:0.3 Mix, the material prepared in this example is marked as 2 # Composite cathode material.

Embodiment 3

[0072] The preparation method of the composite positive electrode material in this embodiment is the same as the preparation method of the composite positive electrode material in Example 1, except that a prepared in step a) in step c) and b prepared in step b) are in a ratio of 0.8:0.2 Mix, the material prepared in this example is marked as 3 # Composite cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com