Multifunctional box culvert pipe gallery concrete and preparation method thereof

A multi-functional, concrete technology, applied in the field of concrete, can solve the problems of unsatisfactory fluidity and self-compacting properties of concrete, hollow, honeycomb and pockmarked surface, large economic burden, etc., to prolong the secondary hydration time and reduce cracking. , the effect of delaying the hydration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

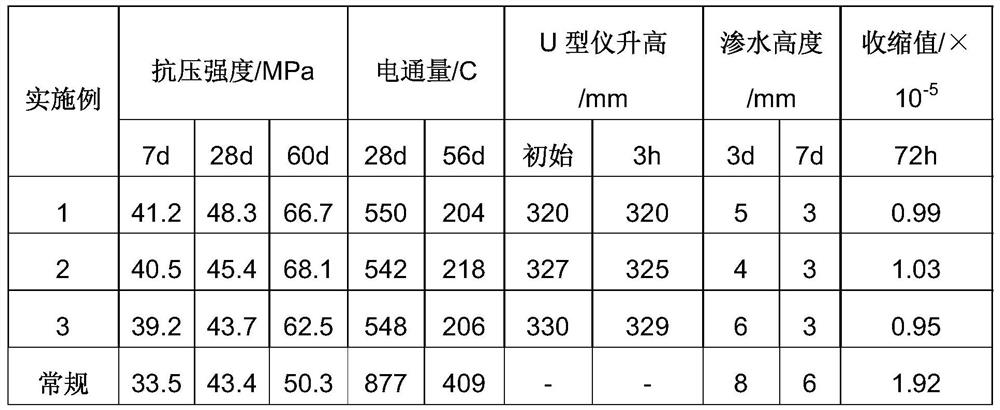

Examples

Embodiment 1

[0026] A preparation method for multifunctional box culvert pipe gallery concrete, comprising the steps of:

[0027] 1. In parts by weight, 25 parts of cement, 8 parts of microbeads, 12 parts of fly ash, 15 parts of natural zeolite and 2.3 parts of composite fiber (PVA: carbon fiber = 5: 5), etc. are discharged to the hopper through the raw material bin Transported in the car to the stirring tank for mixing and stirring for 45s;

[0028] 2. Unload 8 parts of sand material and 9 parts of aggregate into the mixing bin according to the weight and mix them for later use;

[0029] 3. Take by weight 9 parts of polycarboxylic acid mother liquor, 8 parts of polycarboxylate mother liquor, 3 parts of sodium citrate, 0.5 part of plastic powder, 0.02 part of alkylsulfonate air-entraining agent and 0.03 part of polyether disinfectant Stir 80 parts of foaming agent and mixing water evenly to obtain the water reducing agent component for later use;

[0030] 4. Open the resin tank, extract ...

Embodiment 2

[0033] A multifunctional box culvert pipe gallery concrete and a preparation method thereof, comprising the following steps:

[0034] 1. In parts by weight, discharge 22 parts of cement, 6 parts of microbeads, 13 parts of fly ash, 20 parts of natural zeolite and 2 parts of composite fiber (PVA:PP=8:2) into the hopper through the raw material bin Transported in the car to the stirring tank for mixing and stirring for 30s;

[0035] 2. Unload 10 parts of sand and 11 parts of aggregate in parts by weight into the mixing bin and mix for later use;

[0036] 3. Take by weight 12 parts of polycarboxylic acid mother liquor, 7 parts of polycarboxylate mother liquor, 2 parts of sodium citrate, 1 part of plastic powder, 0.01 part of alkylsulfonate air-entraining agent and 0.02 part of polyether disinfectant 78 parts of foaming agent and mixing water were stirred evenly, and the water reducing agent component was obtained for later use;

[0037]4. Open the resin tank, take 6 parts of wat...

Embodiment 3

[0040] A multifunctional box culvert pipe gallery concrete and a preparation method thereof, comprising the following steps:

[0041] 1. In terms of parts by weight, discharge 25 parts of cement, 5 parts of microbeads, 15 parts of fly ash, 12 parts of natural zeolite and 2 parts of composite fiber (PVA:PP=8:2) into the hopper through the raw material bin Transported in the car to the stirring tank for mixing and stirring for 30s;

[0042] 2. Discharge 9 parts of sand material and 14 parts of aggregate into the mixing bin according to the weight and mix them for later use;

[0043] 3. Take by weight 10 parts of polycarboxylic acid mother liquor, 8 parts of polycarboxylate mother liquor, 2 parts of sodium citrate, 1 part of plastic-preserving powder, 0.02 part of alkylsulfonate air-entraining agent and 0.03 part of polyether disinfectant 79 parts of foaming agent and mixing water were stirred evenly, and the water reducing agent component was obtained for later use;

[0044] 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com