Ultra low-alkali portland cement and production method thereof

A portland cement and ultra-low-alkali technology, applied in cement production, etc., can solve problems such as high heat consumption, large water consumption, and less low-alkali cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

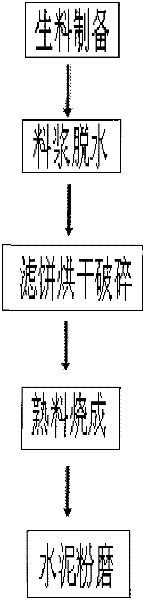

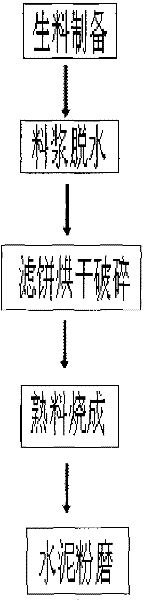

Image

Examples

Embodiment 1

[0034] Raw material preparation: Grind 75% of the calcareous raw material limestone, 15% of the siliceous raw material high-silica sandstone, and 10% of the iron raw material converter slag, and add water to make a slurry, and then filter to obtain a water content of 33 % concentrated slurry.

[0035] Slurry dehydration: the concentrated slurry (water content 33%) is dehydrated by a vacuum suction filter to form a filter cake with water content 19%.

[0036] Filter cake drying and crushing: The filter cake is fed into the drying crusher, and the waste gas (600°C) from the kiln tail is used to dry it into raw meal powder with a water content of 1-3%. The dried exhaust gas is brought into the cyclone separator for material gas separation, and the separated raw meal powder enters the cyclone preheater and decomposition furnace of the firing system, and the exhaust gas (about 150°C) exiting the cyclone separator is used by the kiln tail fan After being sent to the electrostatic pre...

Embodiment 2

[0040] Raw meal preparation: Grind 80.3% calcareous raw material limestone, 12.5% siliceous raw material high-silica sandstone, and 7.2% ferrous raw material converter slag that meet the requirements, and add water to make a slurry, and then filter to obtain a water content of 34 % concentrated slurry.

[0041] Slurry dehydration: the concentrated slurry (water content 34%) is dehydrated by a vacuum suction filter to form a filter cake with water content 20%.

[0042] Filter cake drying and crushing: The filter cake is fed into the drying crusher, and the waste gas (600°C) from the kiln tail is used to dry it into raw meal powder with a water content of 1-3%. The dried exhaust gas is brought into the cyclone separator for material gas separation, and the separated raw meal powder enters the cyclone preheater and decomposition furnace of the firing system, and the exhaust gas (about 150°C) exiting the cyclone separator is used by the kiln tail fan After being sent to the ele...

Embodiment 3

[0046] Raw meal preparation: Grind 85% calcareous raw material limestone, 10% siliceous raw material high-silica sandstone, and 5% iron raw material converter slag that meet the requirements, and add water to make a slurry, and then filter to obtain a water content of 35 % concentrated slurry.

[0047] Slurry dehydration: the concentrated slurry (water content 35%) is dehydrated by a vacuum suction filter to form a filter cake with a water content of 22%.

[0048] Filter cake drying and crushing: The filter cake is fed into the drying crusher, and the waste gas (600°C) from the kiln tail is used to dry it into raw meal powder with a water content of 1-3%. The dried exhaust gas is brought into the cyclone separator for material gas separation, and the separated raw meal powder enters the cyclone preheater and decomposition furnace of the firing system, and the exhaust gas (about 150°C) exiting the cyclone separator is used by the kiln tail fan After being sent to the electrost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com