Retardation pumping type three-expansion source cement expansive material

An expansion agent and concrete technology, applied in the field of concrete expansion agent, can solve the problems of insufficient synchronization of compensation shrinkage, many exposure problems, poor compatibility, etc., and achieve strong adaptability, improved comprehensive physical properties, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

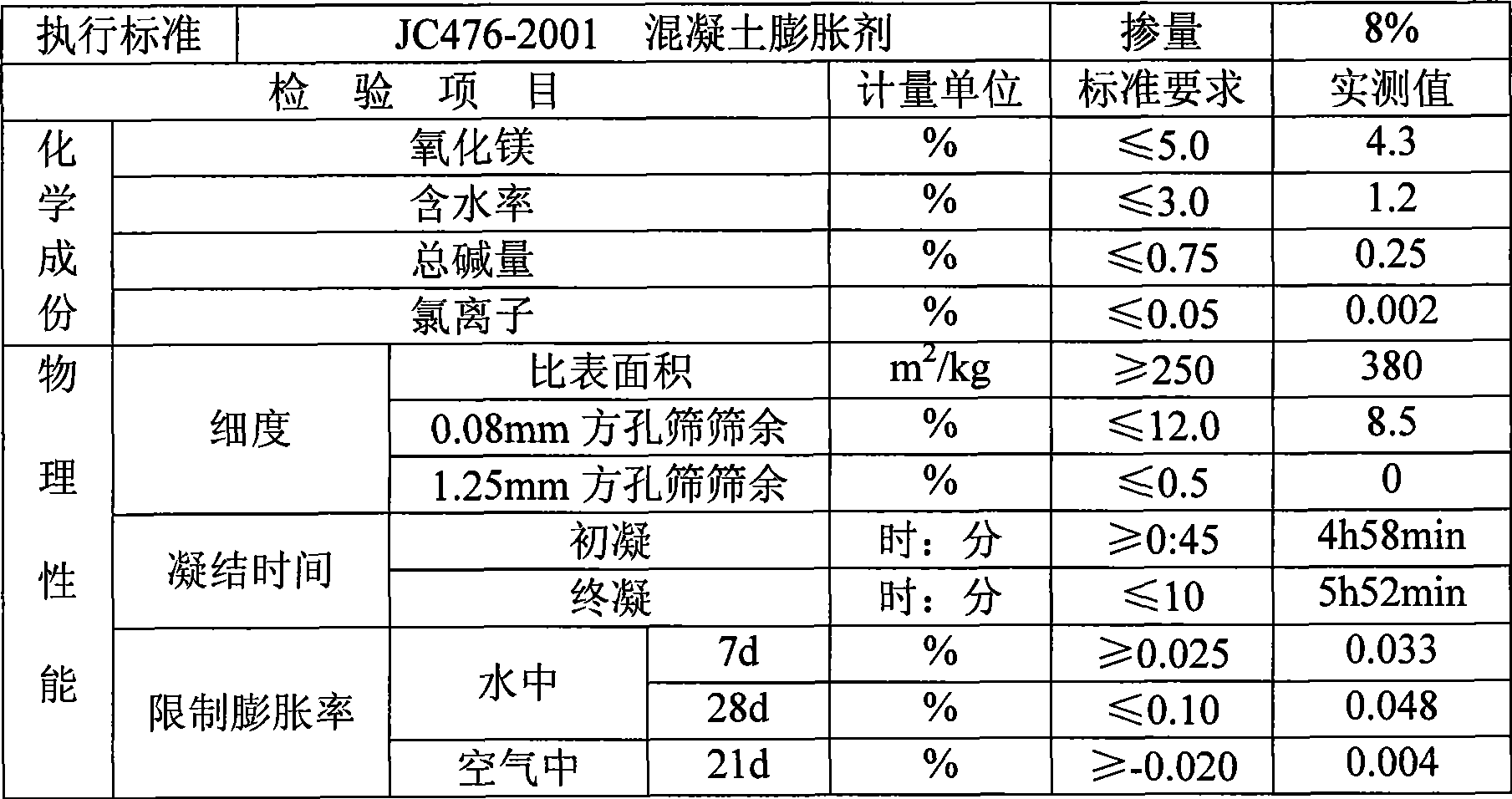

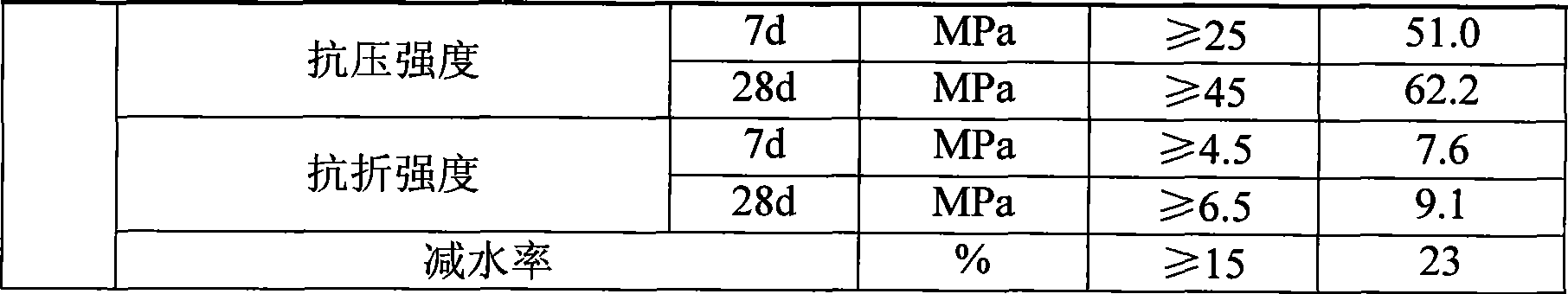

[0063] (1), the preparation process formula is shown in Table 1:

[0064] Table 1 (unit: kg)

[0065] Anhydrite 50 High alumina clinker 10 High Calcium Sulfur Aluminum Clinker 25 Calcined magnesite 3 water slag 12 Polycarboxylate superplasticizer (external mixing) 3.0 Sodium Gluconate (External Mix) 0.6 HPMC cellulose (external blend) 0.02 K12 air-entraining agent (external mixing) 0.04

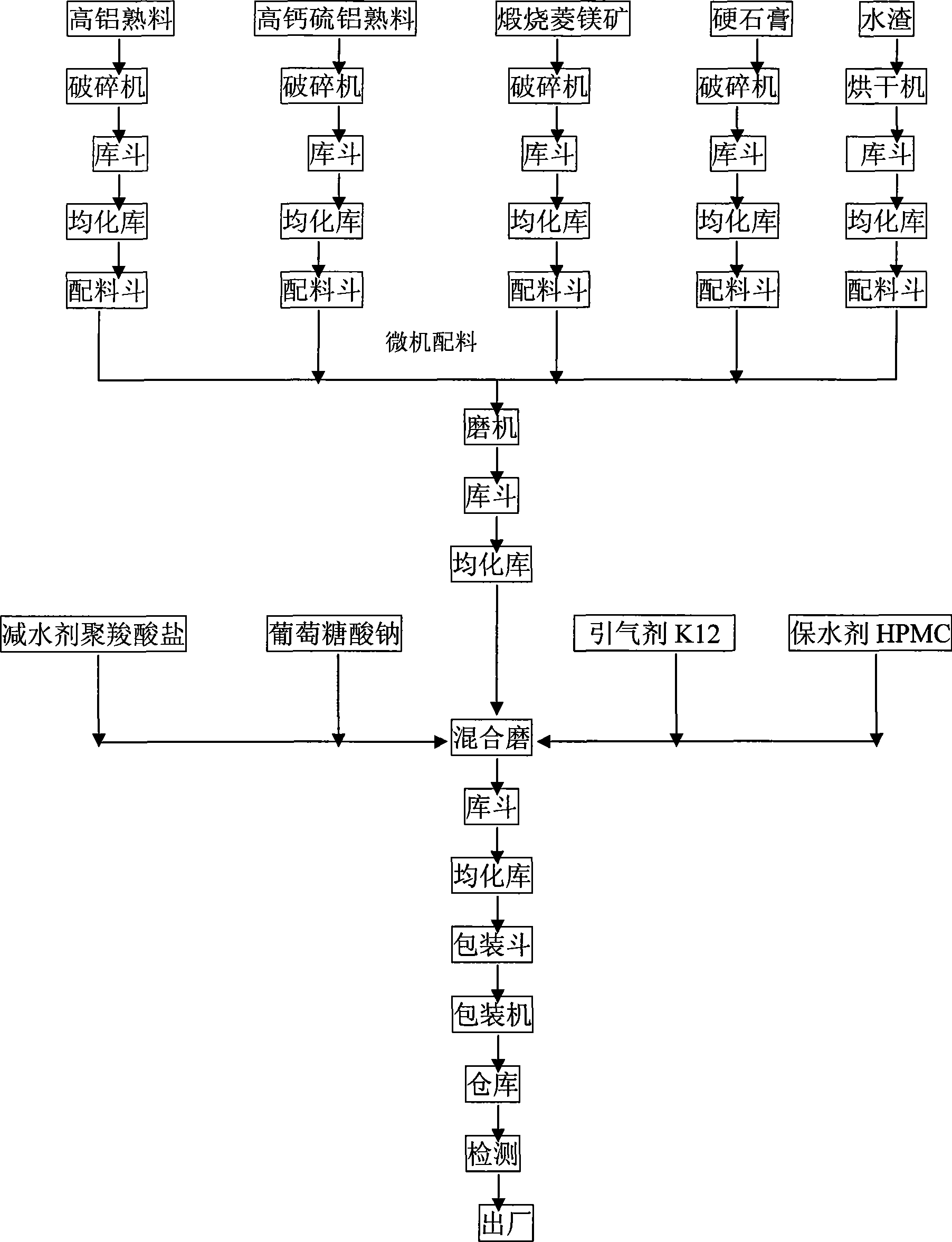

[0066] (2) Preparation process:

[0067] The bulk raw material gypsum, high alumina clinker, high calcium sulfur aluminum clinker, and calcined magnesite are sequentially → The second storehouse → The second homogenization storehouse → Obtain ordinary expansion agent → According to Table 1, mix external materials, externally add water-reducing agent polycarboxylate, water-retaining agent cellulose ether HPMC, air-entraining agent K12 and delay Sodium gluconate → mixed in the third mill → third hopper → third homogenization silo...

Embodiment 2

[0073] (1), the preparation process formula is shown in Table 3

[0074] Table 3 (unit: kg)

[0075] Anhydrite (%) 55 High alumina clinker (%) 10 High calcium sulfur aluminum clinker (%) 30 Calcined magnesite (%) 2 Slag (%) 3 Polycarboxylate superplasticizer (external mixing) (%) 3.0 Sodium gluconate (additional) (%) 0.6 HPMC cellulose (external doping) (%) 0.02 K12 air-entraining agent (external mixing) (%) 0.04

[0076] (2), preparation process:

[0077] The bulk raw material gypsum, high alumina clinker, high calcium sulfur aluminum clinker, and calcined magnesite are sequentially → The second storehouse → The second homogenization storehouse → Obtain ordinary expansion agent → According to Table 1, mix external materials, externally add water-reducing agent polycarboxylate, water-retaining agent cellulose ether HPMC, air-entraining agent K12 and delay Sodium gluconate → mixed in the third mill → third hopper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com