Compound activator and geopolymer cement concrete prepared from same

A composite excitation and geopolymer technology, applied in cement production, etc., can solve the problems of high alkali content in concrete, achieve the effects of improving strength and service life, reducing costs, and high volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

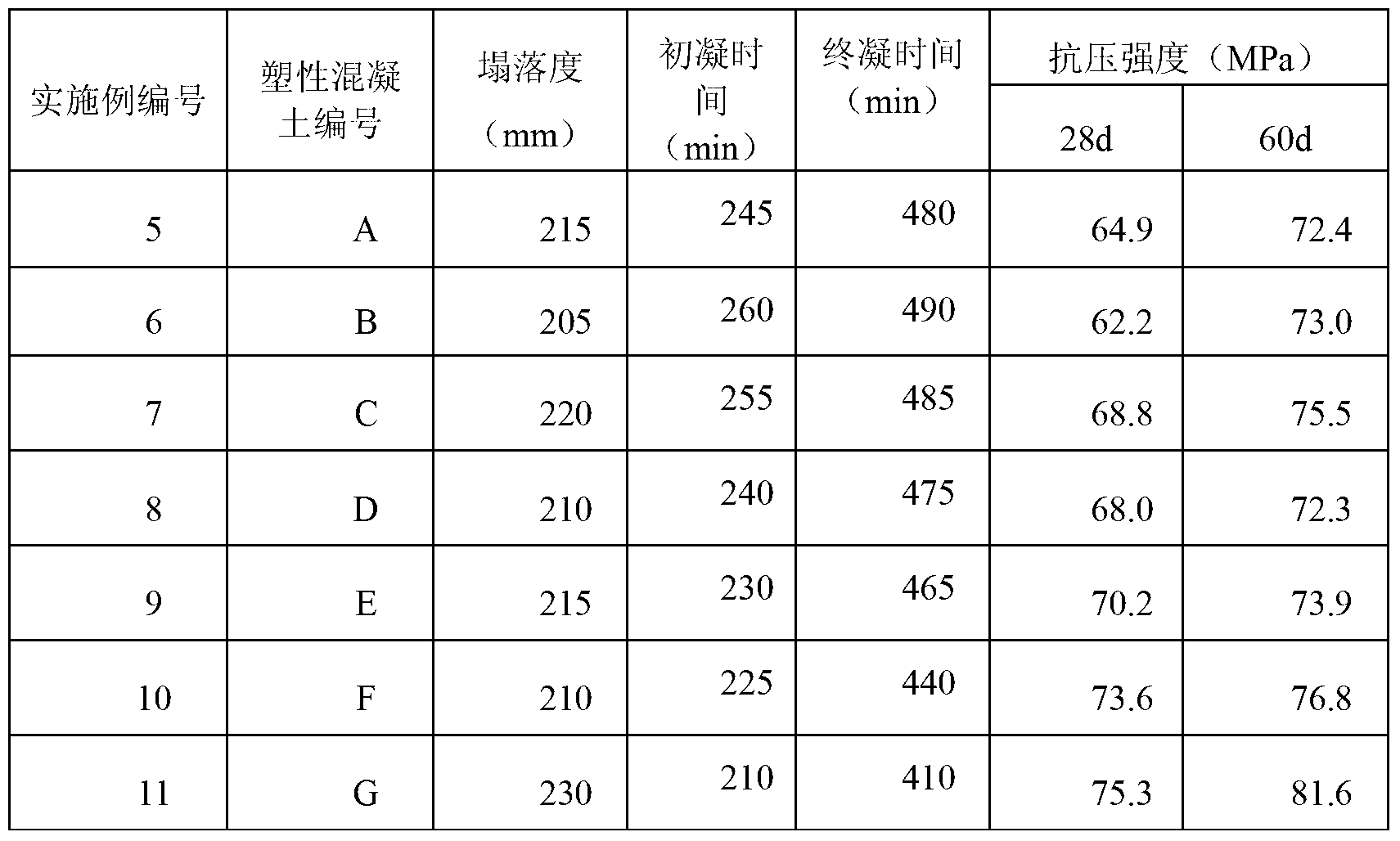

Examples

Embodiment 1

[0031] The composite activator described in this embodiment includes the following raw materials: 0.072kg of triethanolamine, 7.282kg of naphthalene-based water reducer, 116.5kg of quartz powder, and 29.13kg of milk of lime, wherein the milk of lime refers to 30kg The quicklime is added into 60kg of water, stirred evenly, left standing, and obtained after removing the supernatant.

Embodiment 2

[0033] The composite activator described in this embodiment includes the following raw materials: 0.13kg of triethanolamine, 7.819kg of naphthalene-based water reducer, 65.16kg of quartz powder, and 39.09kg of milk of lime, wherein the milk of lime refers to 40kg The quicklime is added into 100kg of water, stirred evenly, left standing, and obtained after removing the supernatant.

Embodiment 3

[0035] The composite activator described in this embodiment includes the following raw materials: 0.26kg of triethanolamine, 8.13kg of naphthalene-based water reducer, 77.46kg of quartz powder, and 51.64kg of milk of lime, wherein the milk of lime refers to 40kg The unslaked lime was added into 120kg of water, stirred evenly, left standing, and obtained after removing the supernatant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com