Method for driving and controlling hoist, hoist and control device for driving and controlling hoist driver

A technology of control device and hoist, which is applied in the control device of the driver and the hoist field of the shaft hoisting system, which can solve the problems of horizontal oscillation and material falling into the shaft, achieve accurate ratings, save time, and can be easily installed The effect of sex and calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

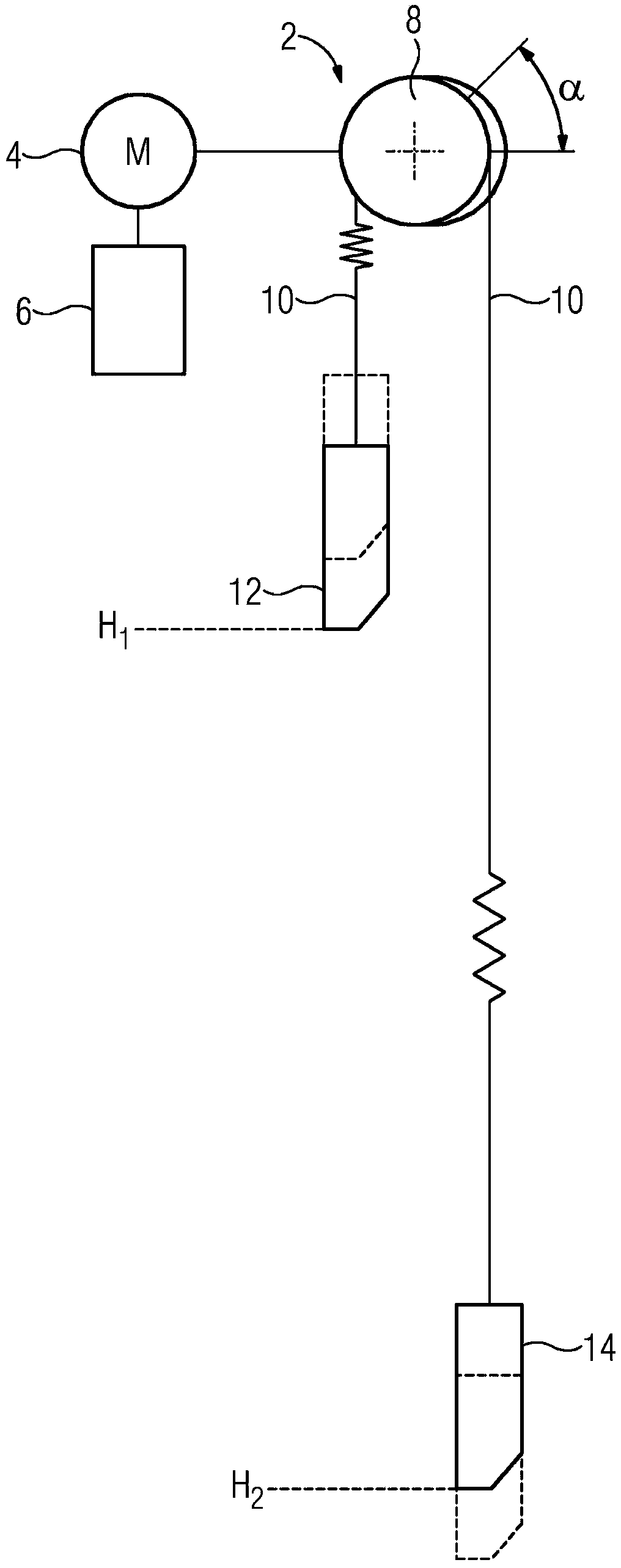

[0020] The single figure here shows a hoist 2 for a shaft hoisting system in a very simplified manner. The hoist has a drive 4 which is controlled by a control device 6 . In the illustrated embodiment, the hoist 2 also comprises: a rigging frame 8 driven by a drive 4; and a hoisting rope 10 with two hoisting containers 12, 14 for vertically conveying Conveyors such as coal or ore. However, the lifting containers 12, 14 can also be used for transporting people.

[0021] In the illustrated embodiment, only one lifting rope is shown. However, it is also possible to use several hoisting cables for suspending the respective hoisting container 12 , 14 .

[0022] The hoist 2 is suitable here for transporting the conveying material in a shaft not shown in detail over a distance of 200 m to 4000 m. The lifting containers 12, 14 are usually at a deeper stop H in the shaft during operation 2 Alternately loading at, conveying upwards and at the higher stop H 1 to uninstall. Here, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com