A kind of plastic for intermediate frequency furnace lining repair and its preparation method

A furnace lining repairing and intermediate frequency furnace technology is applied in the field of plastics for intermediate frequency furnace lining repairing and its preparation, which can solve the problems of short service life, short storage time, low early strength, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

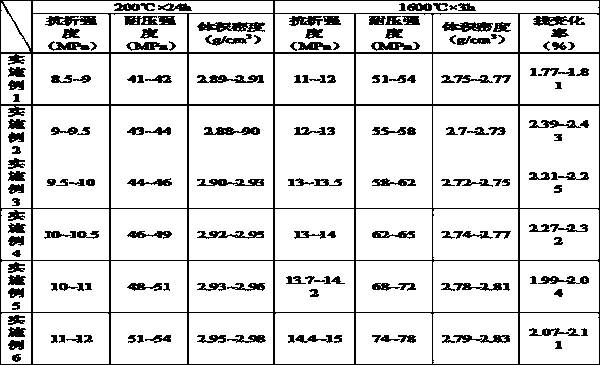

Examples

Embodiment 1

[0029] A plastic material for repairing the lining of an intermediate frequency furnace and a preparation method thereof. Include the following steps:

[0030] 27-30wt% alumina powder, 12-16wt% kyanite, 3-5wt% chromium oxide powder, 2-3wt% plasticizer as the base material, 50-55wt% alumina particles as the Aggregate, the sum of base material and aggregate is the raw material; first mix the base material in the mixer for 1~1.5h, then add the aggregate and the mixed base material into the mixer, and add the The raw materials are 3-5wt% phosphoric acid and 3-5wt% water, mixed and milled for 8-10 minutes to obtain semi-dry mud.

[0031] Put the semi-dry mud into a sealed container, trap the semi-dry mud for 24-48 hours, then add the trapped semi-dry mud into the mixer, add 2-3wt% phosphoric acid, 0.05-0.15wt% of the raw materials % corrosion inhibitor, 0.1-0.5wt% humectant, and 3-5wt% water, mixed and milled for 5-8 minutes to obtain a mixed-milled mud, which was then squeezed i...

Embodiment 2

[0034] A plastic material for repairing the lining of an intermediate frequency furnace and a preparation method thereof. Include the following steps:

[0035] 21-24wt% alumina powder, 18-20wt% kyanite, 2-4wt% chromium oxide powder, 2-3wt% plasticizer as the base material, 50-55wt% alumina particles as the Aggregate, the sum of base material and aggregate is the raw material; first mix the base material in the mixer for 1~1.5h, then add the aggregate and the mixed base material into the mixer, and add the The raw materials are 3-5wt% phosphoric acid and 3-5wt% water, mixed and milled for 8-10 minutes to obtain semi-dry mud.

[0036] Put the semi-dry mud into a sealed container, trap the semi-dry mud for 24-48 hours, then add the trapped semi-dry mud into the mixer, add 2-3wt% phosphoric acid, 0.05-0.15wt% of the raw materials % corrosion inhibitor, 0.1-0.5wt% humectant, and 3-5wt% water, mixed and milled for 5-8 minutes to obtain a mixed-milled mud, which was then squeezed i...

Embodiment 3

[0039] A plastic material for repairing the lining of an intermediate frequency furnace and a preparation method thereof. Include the following steps:

[0040] 23-27wt% alumina powder, 11-14wt% kyanite, 3-5wt% chromium oxide powder, 3-4wt% plasticizer as the base material, 55-60wt% alumina particles as the Aggregate, the sum of base material and aggregate is the raw material; first mix the base material in the mixer for 1~1.5h, then add the aggregate and the mixed base material into the mixer, and add the The raw materials are 3-5wt% phosphoric acid and 3-5wt% water, mixed and milled for 8-10 minutes to obtain semi-dry mud.

[0041] Put the semi-dry mud into a sealed container, trap the semi-dry mud for 24-48 hours, then add the trapped semi-dry mud into the mixer, add 2-3wt% phosphoric acid, 0.05-0.15wt% of the raw materials % corrosion inhibitor, 0.1-0.5wt% humectant, and 3-5wt% water, mixed and milled for 5-8 minutes to obtain a mixed-milled mud, which was then squeezed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com