Preparation method and application of multifunctional antibacterial hydrogel dressing

A hydrogel, multifunctional technology, applied in application, pharmaceutical formulation, medical science, etc., can solve the problems of antibiotic drug abuse, poor mechanical properties of wound dressings, lack of adhesion performance, etc., and achieve durable antibacterial ability and significant antibacterial effect , promoting cell migration and hemostasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of multifunctional antibacterial hydrogel dressing of the present invention, the method comprises the steps:

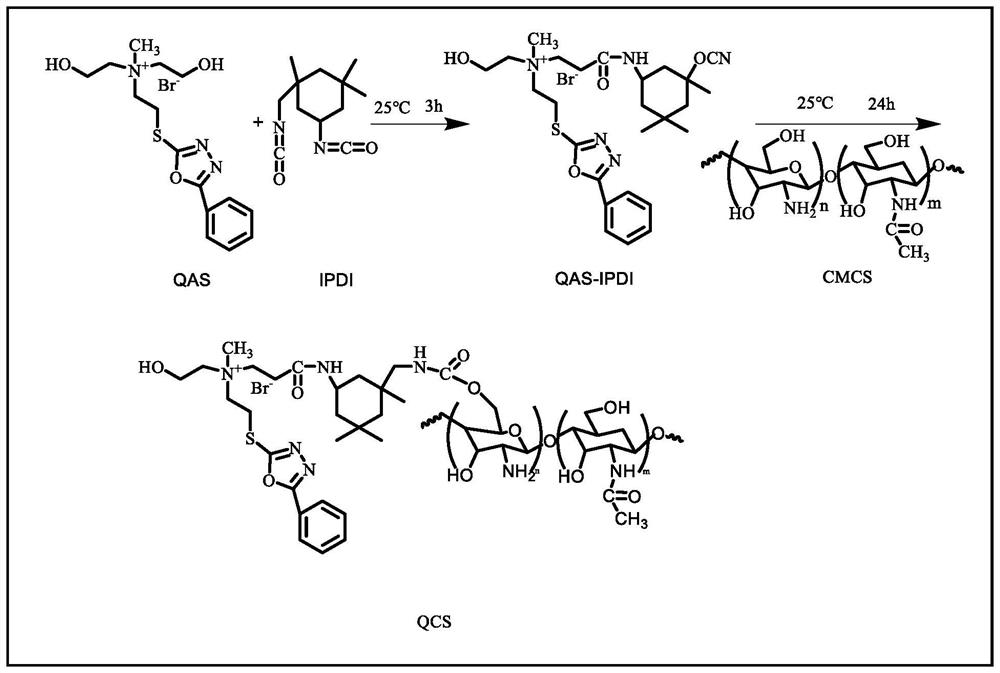

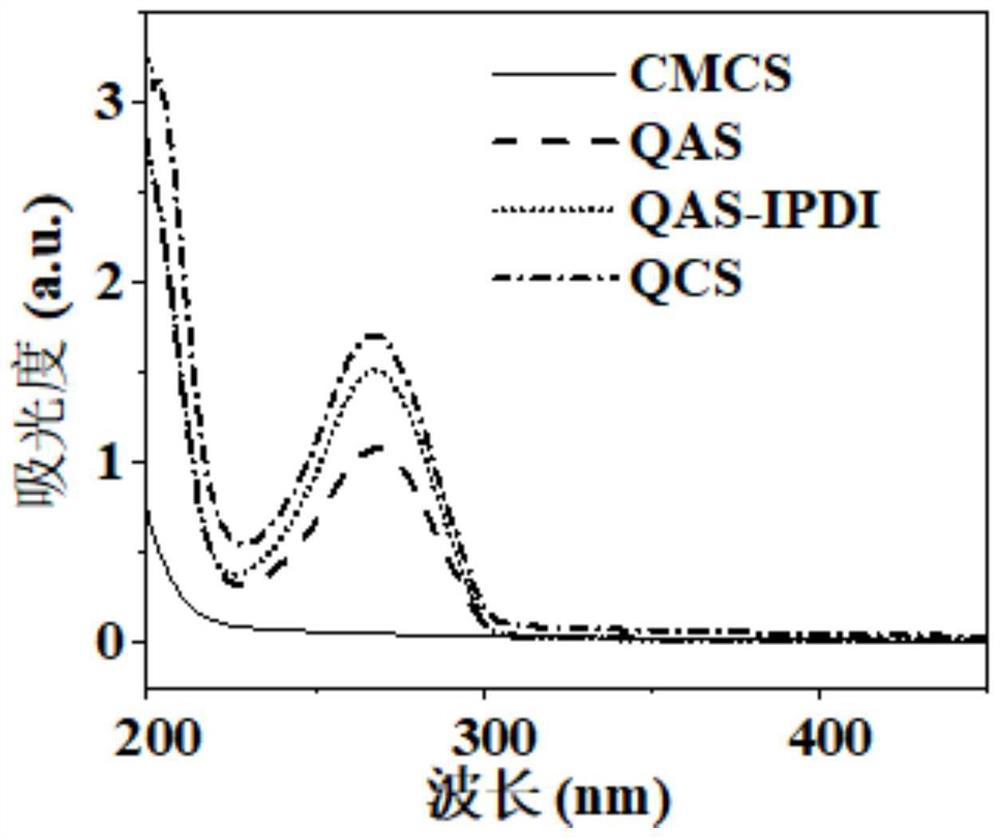

[0061] A The dihydroxy and oxadiazolyl modified quaternary ammonium salts (QAS) with excellent antibacterial properties are coupled to the natural antibacterial active polysaccharide carboxymethyl chitosan with better water solubility through isophorone diisocyanate (IPDI) sugar, to construct a novel quaternized carboxymethyl chitosan (QCS).

[0062] B Functionalization of two-dimensional photothermal material (GO) with 3-aminophenylboronic acid (PBA) and reduction reaction to prepare functionalized reduced graphene oxide (rGB) to increase cell affinity and prevent GO from occurring in hydrogel reunion phenomenon. In addition, phenylboronic acid can form boronate bonds with glycans on the bacterial surface for bacterial immobilization. rGB can be loaded onto the hydrogel through the diol bond on the PBA through subsequent chemical react...

Embodiment 1

[0067] The preparation of embodiment 1 quaternized carboxymethyl chitosan (QCS)

[0068] Take 0.275g (1.24mmol) of IPDI and 0.5g (1.24mmol) of QAS into a 25mL round bottom flask, add 10mL of DMF solution, and stir the mixture at 800-1000rpm / min at 25°C for 3h, and simultaneously Protected under a dry nitrogen atmosphere, and the progress of the reaction was detected by TLC. After the reaction was completed, precipitate with anhydrous ether at -4°C and repeat the operation three times. The precipitate was dried in vacuo to obtain 0.54 g (1.18 mmol) of the solid product QAS-IPDI.

[0069] The above product and CMCS (0.839g, the molar ratio of CMCM and QAS-IPDI is 1:0.3) were reacted in 20mL of DMF at 25°C for 24h with continuous stirring, the magnetic stirring speed was controlled at 800-1000rpm / min, and a dry nitrogen atmosphere was protected at the same time. . After the reaction was completed, the resulting mixed solution was placed in a dialysis bag with a molecular weigh...

Embodiment 4

[0073] Example 4 Preparation of phenylboronic acid functionalized reduced graphene oxide (rGB)

[0074]2 mL of graphene oxide (GO) (5 mg / mL) aqueous solution was placed in a 50 mL glass flask, and 18 mL of deionized water was added, followed by ultrasonic dispersion treatment for 30 min. Then, 30 mg of 3-aminophenylboronic acid (PBA) was added to the above solution, and the reaction was performed under vigorous magnetic stirring at 1200 rpm / min at 70° C. for 3 h in a water bath. Under these conditions, 3-aminophenylboronic acid-functionalized graphene oxide (GB) was prepared. After the reaction was completed, 20 mg of sodium ascorbate was added to the mixture obtained above, the temperature of the water bath was increased to 80° C. and the original stirring speed was kept stirring continuously, and the reaction was continued for 1 h. After the reaction was completed, it was naturally cooled to room temperature, and the resulting mixed solution was transferred to a centrifuge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com