Packaging structure of luminous semiconductor chip and packaging method thereof

A light-emitting semiconductor and packaging structure technology, which is applied in the field of lighting, can solve the problems of reducing luminous efficiency, limiting the scope of use, and difficulty in the amount of glue, and achieves the effects of improving the heat dissipation environment, popularizing and using a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

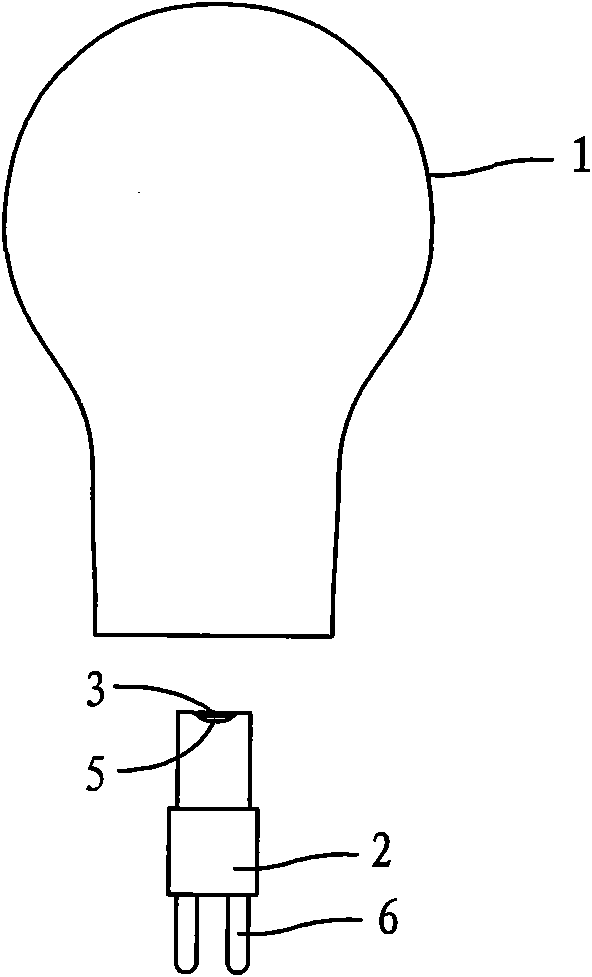

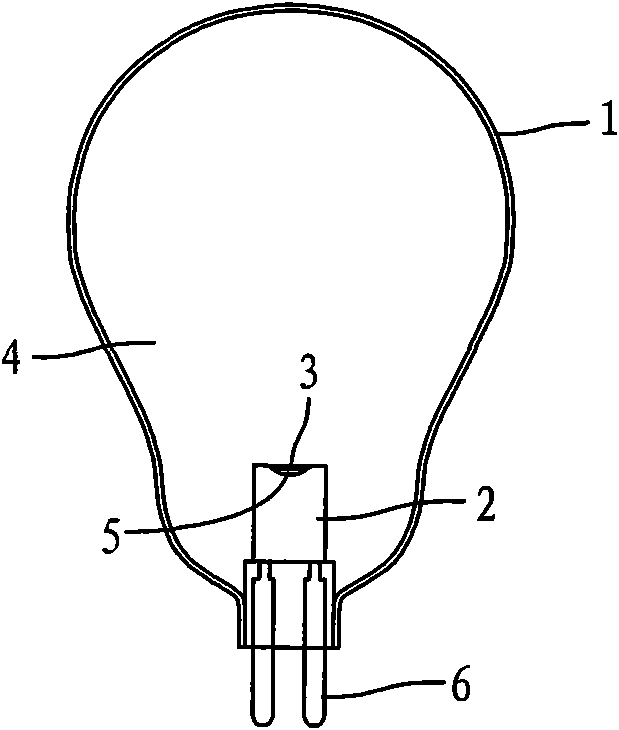

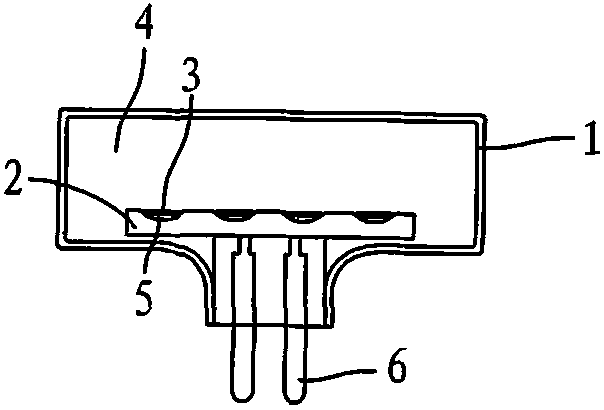

[0026] Such as Figures 1 to 6 As shown, the packaging structure of the light-emitting semiconductor chip according to the present invention includes a light-emitting semiconductor chip 3 and a lampshade 1. The light-emitting semiconductor chip 3 is fixed on the light-emitting semiconductor chip bracket 2, and the light-emitting semiconductor chip bracket 2 and The light-emitting semiconductor chip bracket 2 is electrically connected to the power supply according to the connection mode of the existing LED lamps, such as two pins 6 protruding from its lower part are electrically connected to the power supply; the lower end of the lampshade 1 is open, and it passes through the opening. It is fixedly connected with the light-emitting semiconductor chip bracket 2 to form a closed cavity 4, so that the light-emitting semiconductor chip 3 is located in the closed cavity 4, isolated from the outside world and oxygen, not easy to be oxidized, and can also prevent moisture. The light-e...

Embodiment 2

[0040] Such as Figure 7 As shown, the packaging structure of the light-emitting semiconductor chip according to the present invention includes a light-emitting semiconductor chip 3 and a lampshade 1. The light-emitting semiconductor chip 3 is fixed on the light-emitting semiconductor chip bracket 2; Composed with the transparent cover 9, the lower part of the lamp cup 8 is fixedly connected with the light-emitting semiconductor chip bracket, the upper end of the lamp cup is open, and it is fixedly connected with the transparent cover 9 through the opening to form a closed cavity 4, and the light-emitting semiconductor chip 3 is located in the cavity 4. The light-emitting semiconductor chip 3 is isolated from the outside world and oxygen, not easy to be oxidized, and also moisture-proof. The surface of the light-emitting semiconductor chip bracket 2 can be flat, inwardly recessed arc-shaped or irregular, and the light-emitting semiconductor chips 3 are evenly distributed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com