igbt module unit for flexible direct current transmission

A flexible DC power transmission, modular unit technology, applied in electrical components, output power conversion devices, cooling/ventilation/heating renovation, etc., can solve the problems of complex installation structure, reduce installation parts, extend service life, simplify The effect of installing the crimp structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

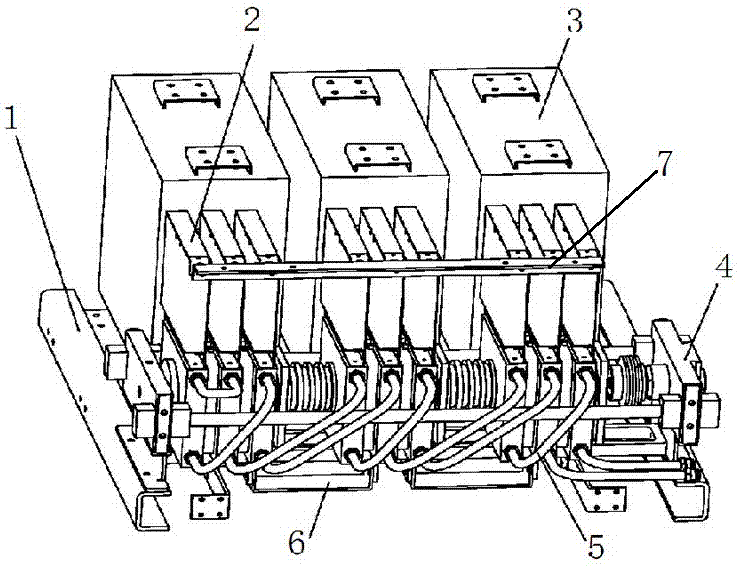

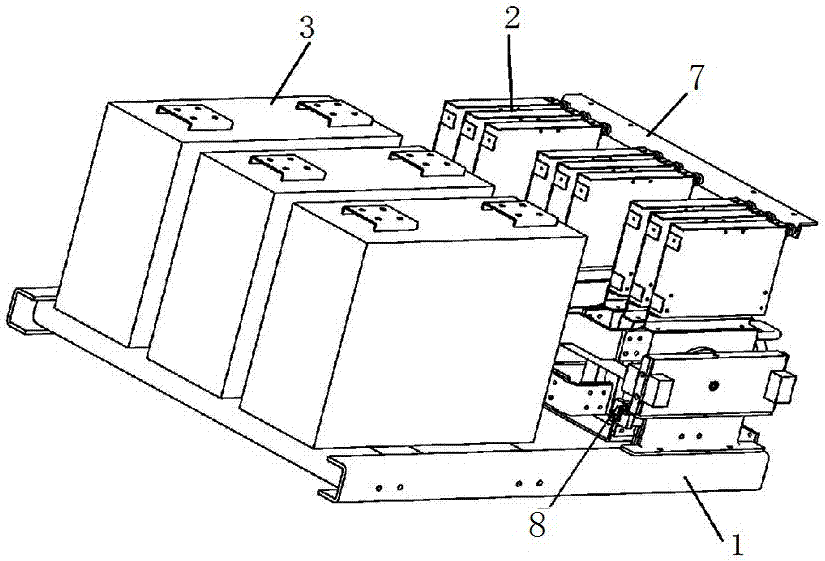

[0023] Such as Figure 1 to Figure 5 As shown, an embodiment of an IGBT module unit for flexible direct current transmission, the IGBT module unit in this embodiment includes a mounting frame 1, and a sub-module crimping unit 4 is fixed on the front of the mounting frame 1, and the sub-module crimping unit A plurality of sub-modules 40 are crimped on the 4, capacitors 3 that are electrically connected to each sub-module are fixed at the rear of the installation frame 1, and a capacitor 3 is installed above the sub-modules 40 at the front of the installation frame 1. There are support slide rails 7 extending along the left and right directions, and the loop control boxes 2 are movably mounted on the support slide rails 7 and electrically connected to each sub-module and each capacitor in one-to-one correspondence.

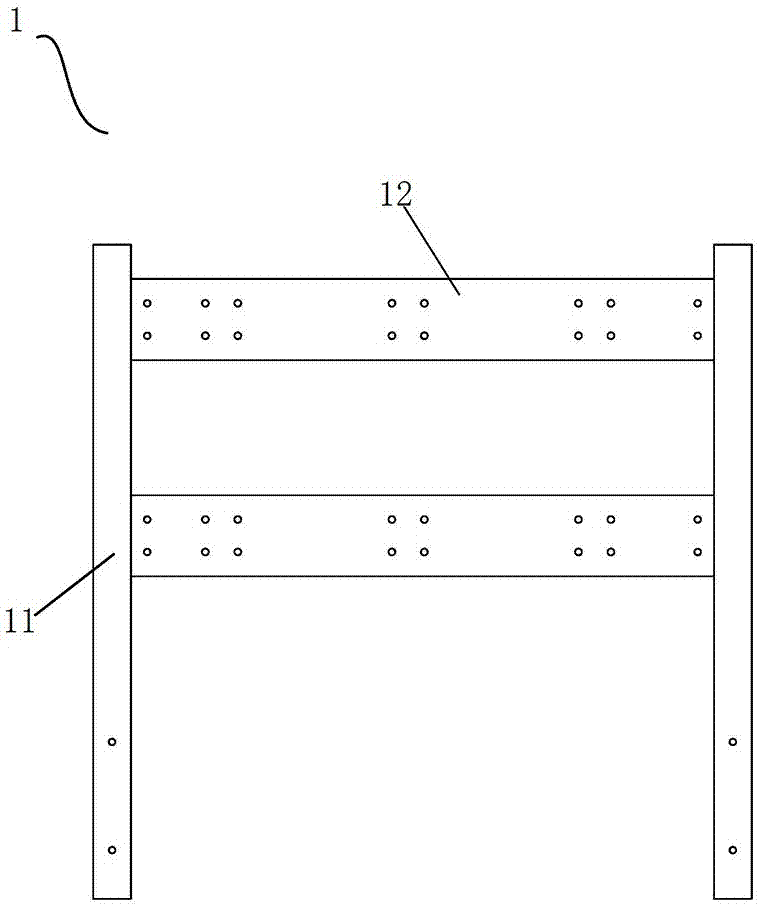

[0024] Such as image 3 As shown, the installation frame 1 includes two supporting beams 11 arranged at intervals along the left and right directions, parallel arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com