Stretch bender oil mist sprayer

A technology of stretch straightening and spraying devices, which is applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of poor oxidation resistance and easy scratches on the surface of finished products, achieve enhanced anti-oxidation effects, prevent scratches, and be good The effect of anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

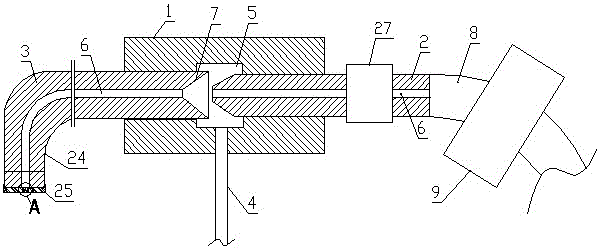

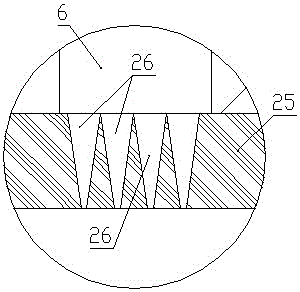

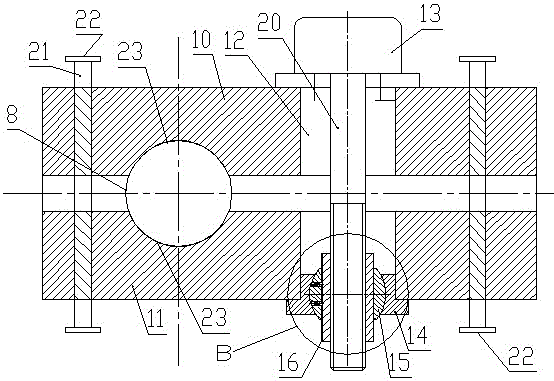

[0022] Such as Figure 1 to Figure 7 As shown, the oil mist spraying device for tension straightening machine of the present invention comprises a housing 1, and the housing 1 is sealed and connected with an inlet pipe 2, an air outlet pipe 3 and an oil inlet pipe 4, and a buffer chamber 5 is provided in the housing 1; The flow direction is forward, the front end of the air inlet pipe 2 and the rear end of the air outlet pipe 3 are all located in the buffer chamber 5, the front end of the air inlet pipe 2 is facing the rear end of the air outlet pipe 3 and a gap is provided between the two (both are the same axis setting); the air inlet pipe 2 and the air outlet pipe 3 are respectively provided with a gas passage 6 along the axis, and the rear end 7 of the air passage 6 in the air outlet pipe 3 is in the shape of a bell mouth with a large outside and a small inside.

[0023] The casing 1 and the intake pipe 2 are preferably fitted in a sliding and sealing manner. The front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com