Method for preventing enameled wires from being oxidized and device for implementing method

An anti-oxidation and enameled wire technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of bare copper wire oxidation, waste of steam resources, and high production costs, achieve good oxidation resistance, improve utilization, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

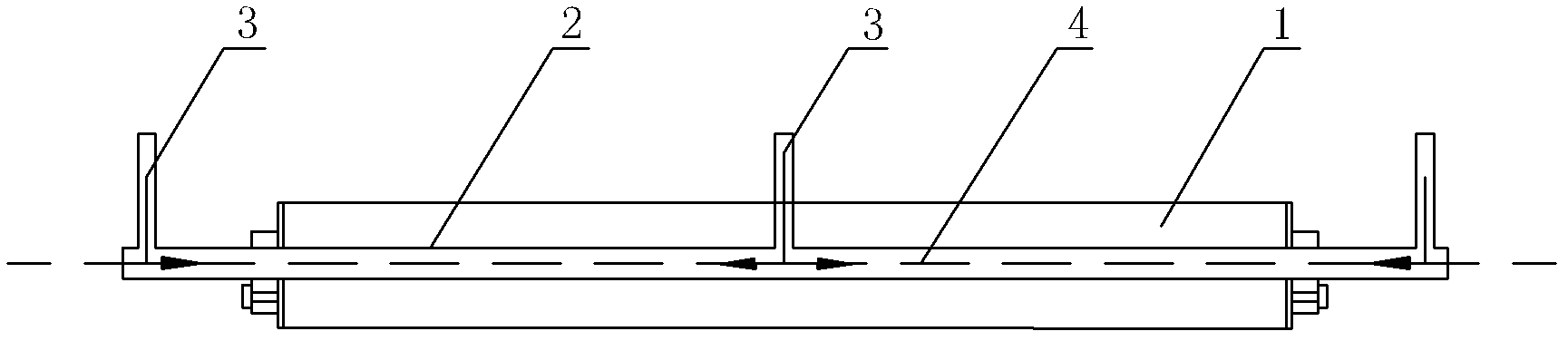

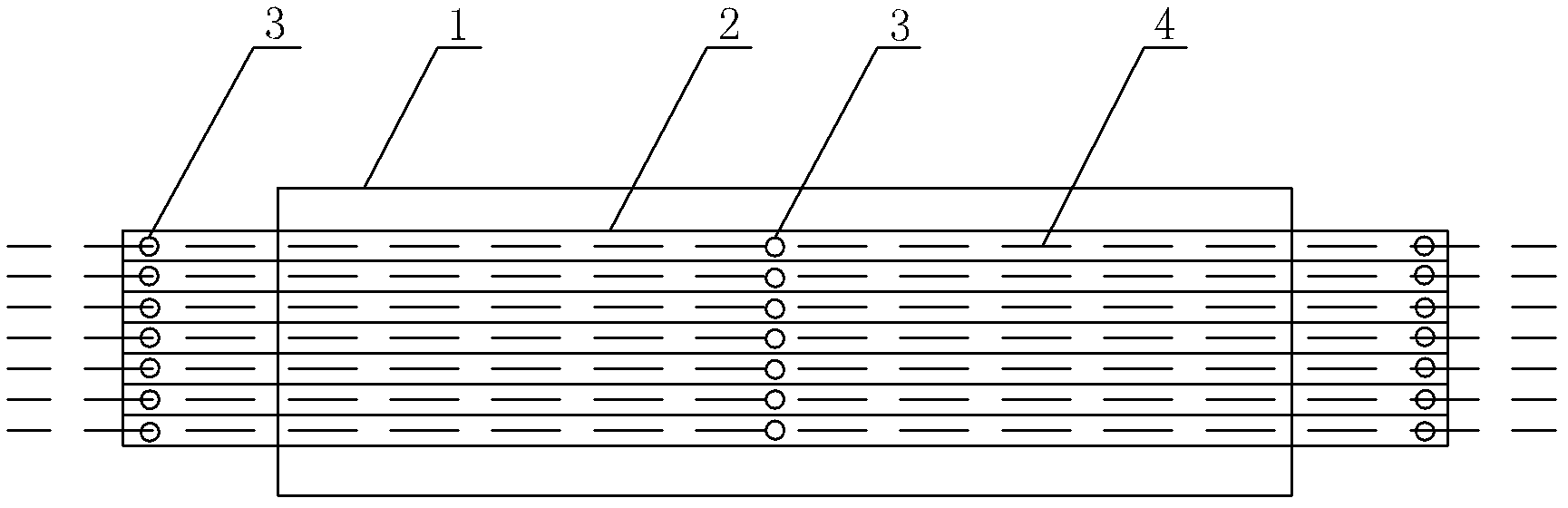

[0017] Such as figure 1 , 2 The shown annealing furnace includes a furnace body 1 and an annealing pipeline 2 passing through the furnace body 1 . Several annealing pipes 2 are provided, and several annealing pipes 2 are arranged in parallel.

[0018] Both ends of each annealing pipeline 2 are connected with a steam pipeline 3, and the middle of the annealing pipeline 2 is also connected with a steam pipeline 3, and the steam pipeline 3 is connected with a steam generating device.

[0019] The operation method of the present embodiment is set forth in detail below:

[0020] The copper wire 4 enters the furnace body 1 through the annealing pipe 2 for annealing treatment after being unwound, and the steam pipes 3 at both ends are opened to spray steam into the annealing pipe 2; When the steam is injected, the steam at both ends travels to the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com