Magnet for micro-electronic water pump rotor and preparation method thereof

A technology of electronic water pump and manufacturing method, which is applied in the manufacture of stator/rotor body, permanent magnet manufacturing, inductor/transformer/magnet manufacturing, etc. It can solve the problems of acid and alkali resistance, solvent resistance and oxidation resistance, and insufficient magnetic properties, etc. problem, to achieve the effect of improving affinity, reducing volume and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

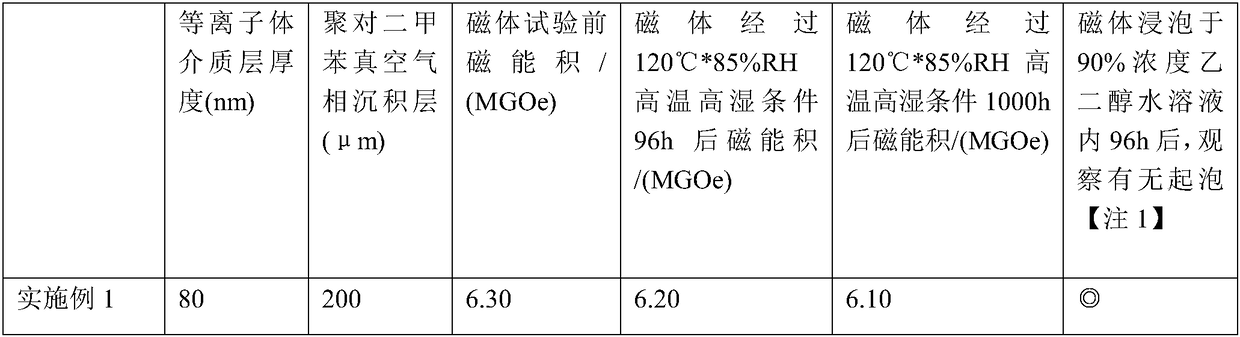

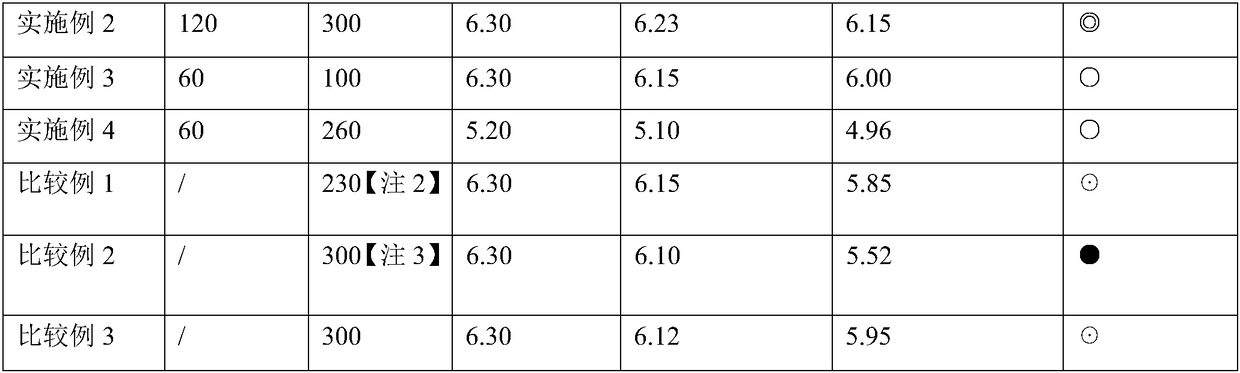

Embodiment 1

[0042] A magnet for the rotor of a miniature electronic water pump, including a magnet body, the magnet body is an injection-molded polyphenylene sulfide PPS-NdFeB magnet; the magnetic energy product of the magnet body is 6.3MGOe; the outer surface of the magnet body is treated by plasma surface modification A low-temperature plasma medium layer with a thickness of 80 nm is formed, and a parylene vacuum vapor-phase deposition layer with a thickness of 200 μm is formed on the outside of the low-temperature plasma medium layer by vacuum vapor deposition on the magnet body.

[0043] Specific preparation method:

[0044] (1) Select the commercially available injection molding polyphenylene sulfide PPS-NdFeB pellets (brand TRP-N760, magnetic energy product 6.3MGOe), use the injection molding machine produced by Arburg, Germany, and inject at the injection temperature of 310-330 °C Injection-molded polyphenylene sulfide PPS-NdFeB water pump rotor magnet to form the magnet body;

[...

Embodiment 2

[0049] A magnet for the rotor of a miniature electronic water pump, including a magnet body, the magnet body is an injection-molded polyphenylene sulfide PPS-NdFeB magnet; the magnetic energy product of the magnet body is 6.3MGOe; the outer surface of the magnet body is treated by plasma surface modification A low-temperature plasma medium layer with a thickness of 120 nm is formed, and a parylene vacuum vapor-phase deposited layer with a thickness of 300 μm is formed outside the low-temperature plasma medium layer by a vacuum vapor deposition method on the magnet body.

[0050] Specific preparation method:

[0051] (1) Select commercially available injection molding PPS-NdFeB granules (brand TRP-N760, magnetic energy product 6.3MGOe), use the injection molding machine produced by Arburg, Germany, and inject injection molding PPS- Magnet for NdFeB water pump rotor, forming the magnet body;

[0052] (2) On the outer surface of the (1) injection molded magnet body, a plasma med...

Embodiment 3

[0056] A magnet for the rotor of a miniature electronic water pump, including a magnet body, the magnet body is an injection-molded polyphenylene sulfide PPS-NdFeB magnet; the magnetic energy product of the magnet body is 6.3MGOe; the outer surface of the magnet body is treated by plasma surface modification A low-temperature plasma medium layer with a thickness of 60 nm is formed, and a parylene vacuum vapor-phase deposition layer with a thickness of 100 μm is formed outside the low-temperature plasma medium layer by a vacuum vapor deposition method on the magnet body.

[0057] Specific preparation method:

[0058] (1) Select commercially available injection molding PPS-NdFeB granules (brand TRP-N760, magnetic energy product 6.3MGOe), use the injection molding machine produced by Arburg, Germany, and inject injection molding PPS- Magnet for NdFeB water pump rotor;

[0059] (2) On the outer surface of (1) the injection molded magnet body, a plasma medium layer is formed by lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com