Anti-oxidation coating for carbon anodes in aluminum electrolysis

An anti-oxidation coating and carbon anode technology, which is applied in the field of high-temperature anti-oxidation coatings for electrolytic aluminum carbon anodes, can solve the problems of the purity of polluted pure aluminum, loss of protection, and poor resistance to fluoride ion corrosion, and achieve good economic benefits and Social benefits, reducing consumption, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

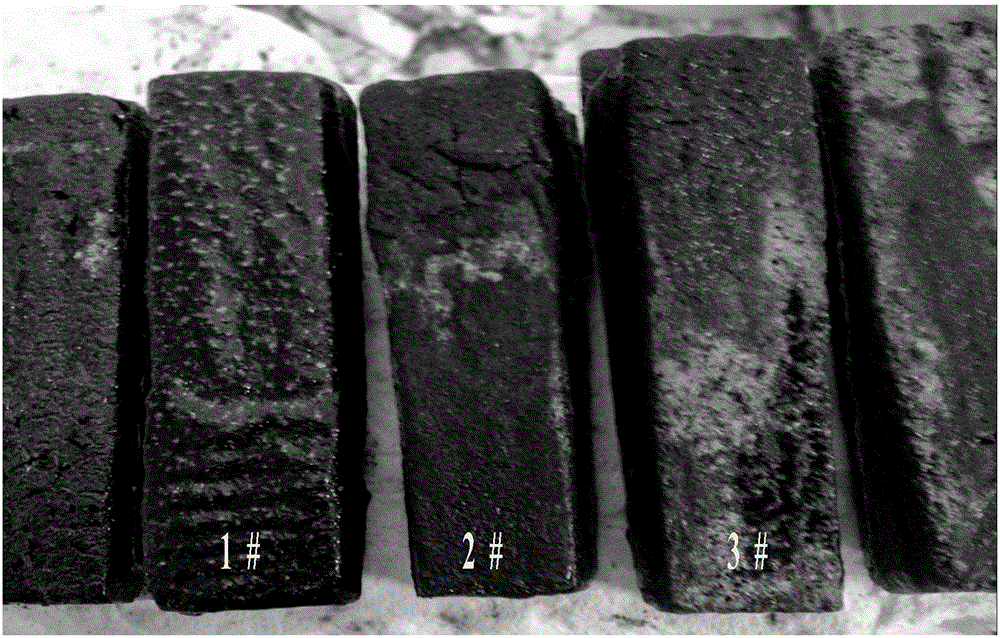

Image

Examples

Embodiment 1

[0022] High-temperature anti-oxidation coating for electrolytic aluminum carbon anode, calculated by weight percentage, alumina powder 30%, sodium fluoride 10%, aluminum fluoride 10%, metal aluminum powder 1.0%, boride 3.0%, water glass 20%, sodium It is prepared by mixing 4% bentonite and 22% water.

Embodiment 2

[0024] High-temperature anti-oxidation coating for electrolytic aluminum carbon anode, calculated by weight percentage, alumina powder 32%, sodium fluoride 12%, aluminum fluoride 10%, metal aluminum powder 0.8%, boride 3.5%, water glass 20%, sodium It is prepared by mixing 3% of base bentonite and 18.7% of water.

Embodiment 3

[0026] High-temperature anti-oxidation coating for electrolytic aluminum carbon anode, calculated by weight percentage, alumina powder 35%, aluminum fluoride 13%, sodium fluoride 10%, metal aluminum powder 0.5%, boride 4.0%, water glass 22%, concave-convex It is prepared by mixing 2% stick clay and 13.5% water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com