Nanometer mixed powder, high-temperature antioxidant coating and application of nanometer mixed powder and high-temperature antioxidant coating

A high-temperature anti-oxidation and mixed powder technology, which is applied in the field of nano-mixed powder and high-temperature anti-oxidation coatings, can solve the problems of single protection mechanism of anti-oxidation coatings, unsatisfactory anti-oxidation protection effect, narrow applicable temperature range, etc., and achieve excellent Oxidation resistance, excellent thermal stability and crack resistance, effect of lowering sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

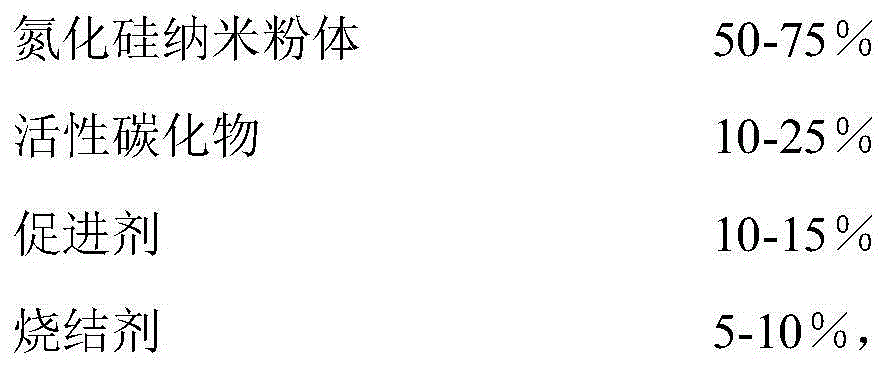

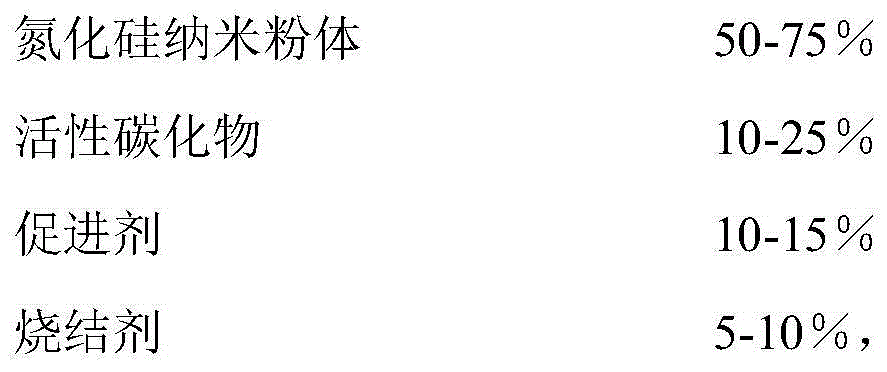

[0051] A high-temperature anti-oxidation coating in this embodiment is composed of nano-mixed powder, binder, dispersant and solvent. Among them, the nano-mixed powder is composed of the following components by weight percentage: 75% of silicon nitride nano-powder, 10% of activated carbide, 10% of accelerator, 5% of sintering agent, Si in the above-mentioned silicon nitride nano-powder 3 N 4 The mass fraction of ≧99%, the average particle size is 30nm; the activated carbide is SiC powder and B 4 The combination of C powder, the particle size is 400-500 mesh, wherein, SiC powder and B 4 The mass ratio of C powder is 2:1, and the mass fraction of SiC in SiC powder is ≧80%, B 4 B in C powder 4 The mass fraction of C≧40%; the accelerator powder includes SiO 2 、Al 2 o 3 and K 2 O+Na 2 O, whose particle size is greater than 400 mesh, and SiO 2 、Al 2 o 3 、K 2 O+Na 2 The content of O is respectively 50%, 35% and 15% of the total mass of the accelerator powder; the sinteri...

Embodiment 2

[0070] A high-temperature anti-oxidation coating in this embodiment is composed of nano-mixed powder, silica sol, sodium polyacrylate, bentonite, and deionized water. Among them, the nano-mixed powder is composed of the following components by weight percentage: 60% of silicon nitride nano-powder, 15% of activated carbide, 15% of accelerator, 10% of sintering agent, Si in the above-mentioned silicon nitride nano-powder 3 N 4 The mass fraction of ≧99%, the average particle size is 30nm; the activated carbide is SiC powder and B 4 The combination of C powder, the particle size is 400-500 mesh, wherein, SiC powder and B 4 The mass ratio of C powder is 3:1, and the mass fraction of SiC in SiC powder is ≧80%, B 4 B in C powder 4 The mass fraction of C≧40%; the accelerator powder includes SiO 2 、Al 2 o 3 and K 2 O+Na 2 O, whose particle size is greater than 400 mesh, and SiO 2 、Al 2 o 3 、K 2 O+Na 2 The content of O is respectively 50%, 30% and 20% of the total mass of t...

Embodiment 3

[0082] A high-temperature anti-oxidation coating in this embodiment is composed of nano-mixed powder, silica sol, sodium polyacrylate, bentonite, and deionized water. Among them, the nano-mixed powder is composed of the following components by weight percentage: 50% of silicon nitride nano-powder, 25% of activated carbide, 15% of accelerator, 10% of sintering agent, Si in the above-mentioned silicon nitride nano-powder 3 N 4 The mass fraction of SiC in SiC powder is ≧99%, and the average particle size is 30nm; the activated carbide is SiC powder, and its particle size is 400-500 mesh, wherein, the mass fraction of SiC in SiC powder is ≧80%; the accelerator powder includes SiO 2 、Al 2 o 3 and K 2 O+Na 2 O, whose particle size is greater than 400 mesh, and SiO 2 、Al 2 o 3 、K 2 O+Na 2 The content of O is 55%, 35% and 10% of the total mass of the accelerator powder respectively; the sintering agent is Fe with a mass fraction ≧80% 3 o 4 , and its particle size is greater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com