Novel aluminum steel continuous casting tundish covering agent and application thereof

A technology of continuous casting tundish and covering agent, which is applied in the field of continuous casting of iron and steel, which can solve the problems that it is not suitable for continuous casting of aluminum-containing steel, and does not take into account the reaction between molten steel and tundish covering agent steel slag, etc., to achieve the suppression of the slag-steel interface Effect of reaction, reduction of viscosity and interfacial tension, and increase of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

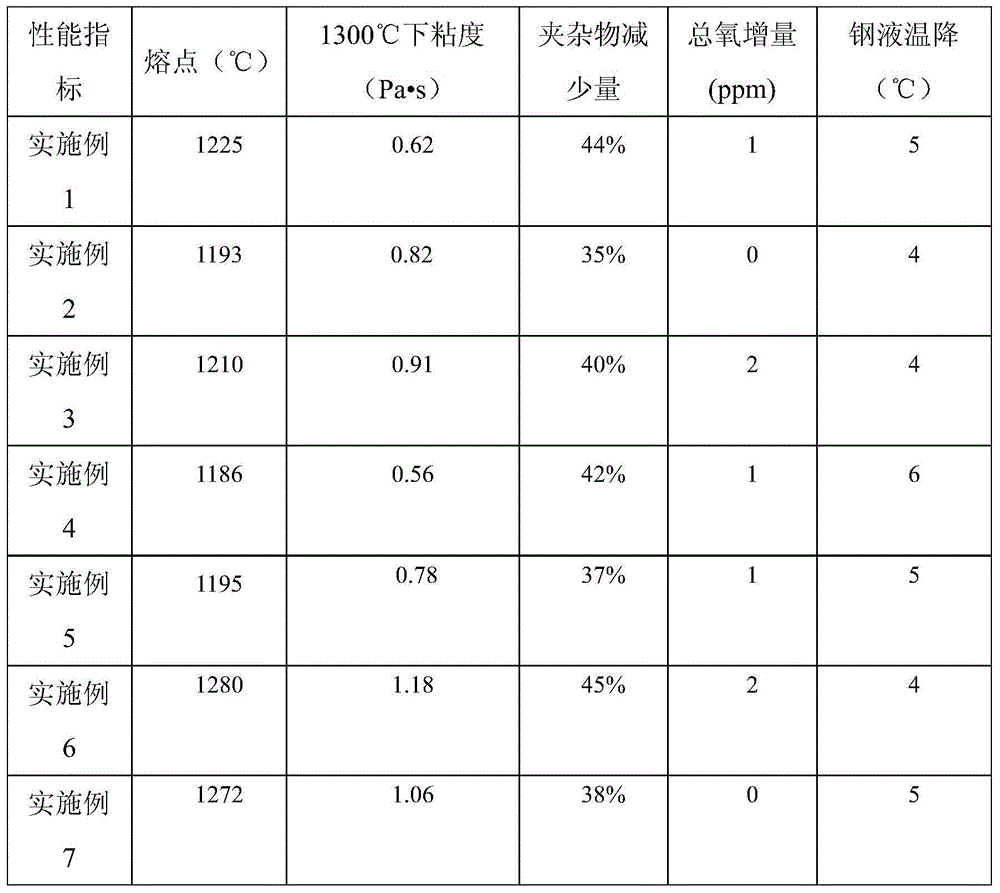

Embodiment 1

[0034] A new aluminum-containing steel continuous casting tundish covering agent, its composition mass percentage is: CaO 28%, SiO 2 8%, Al 2 o 3 32%, MgO 12%, (Na 2 O+Li 2O) 14% (Na 2 O / Li 2 O=13:1 mass ratio), B 2 o 3 6%. The basicity of the tundish covering agent CaO / SiO 2 is 3.5. The main physical properties of the tundish covering agent measured by the above method are shown in Table 1. The tundish covering agent designed in this embodiment is used for the continuous casting process of aluminum-containing steel with an Al mass percentage content of 3%; after testing, the total amount of inclusions in the molten steel decreases by 44% before and after the tundish, and the total oxygen content is only With an increase of 1 ppm, the temperature of molten steel drops by 5°C.

Embodiment 2

[0036] A new aluminum-containing steel continuous casting tundish covering agent, its composition mass percentage is: CaO 30%, SiO 2 6%, Al 2 o 3 30%, MgO 12%, (Na 2 O+Li 2 O) 15% (Na 2 O / Li 2 O=30:1 mass ratio), B 2 o 3 7%. The basicity of the tundish covering agent CaO / SiO 2 for 5. The main physical properties of the tundish covering agent measured by the above method are shown in Table 1. The tundish covering agent designed in this embodiment is used for the continuous casting process of aluminum-containing steel with an Al mass percentage content of 2.5%; after testing, the total amount of inclusions in molten steel decreases by 35% before and after passing through the tundish, and the total oxygen content does not increase, the molten steel temperature drops by 4°C.

Embodiment 3

[0038] A new aluminum-containing steel continuous casting tundish covering agent, its composition mass percentage is: CaO 35%, SiO 2 13%, Al 2 o 3 27%, MgO 5%, (Na 2 O+Li 2 O) 12% (Na 2 O / Li 2 O=11:1 mass ratio), B 2 o 3 8%. The basicity of the tundish covering agent CaO / SiO 2 is 2.7. The main physical properties of the tundish covering agent measured by the above method are shown in Table 1. The tundish covering agent designed in this embodiment is used in the continuous casting process of aluminum-containing steel with an Al mass percentage of 0.3%; after testing, the total amount of inclusions in molten steel decreases by 40% before and after passing through the tundish, and the total oxygen content only increases 2 ppm, the temperature of molten steel drops by 4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com