Special protective paint for expressway crash barrier, and preparation method thereof

A technology for anti-collision guardrails and protective paint, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve problems such as galvanized layer peeling off, loss of anti-collision function, and impact on vehicle traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the special protective paint for the above-mentioned expressway anti-collision guardrail consists of the following steps:

[0025] (1) Take by weighing the number of components of each component in claim 2 or 3 or 4 or 5, put acrylic resin, epoxy resin, butanol, acrylic fat, thinner, drier into the reactor and carry out stirring treatment , the stirring time is 1h, and the rotating speed is 280-530 rpm;

[0026] (2) Add the dispersant and defoamer into step 1, and then carry out the stirring treatment again, the stirring time is 1.5h, and the rotation speed is 400-600 rpm to obtain the finished product.

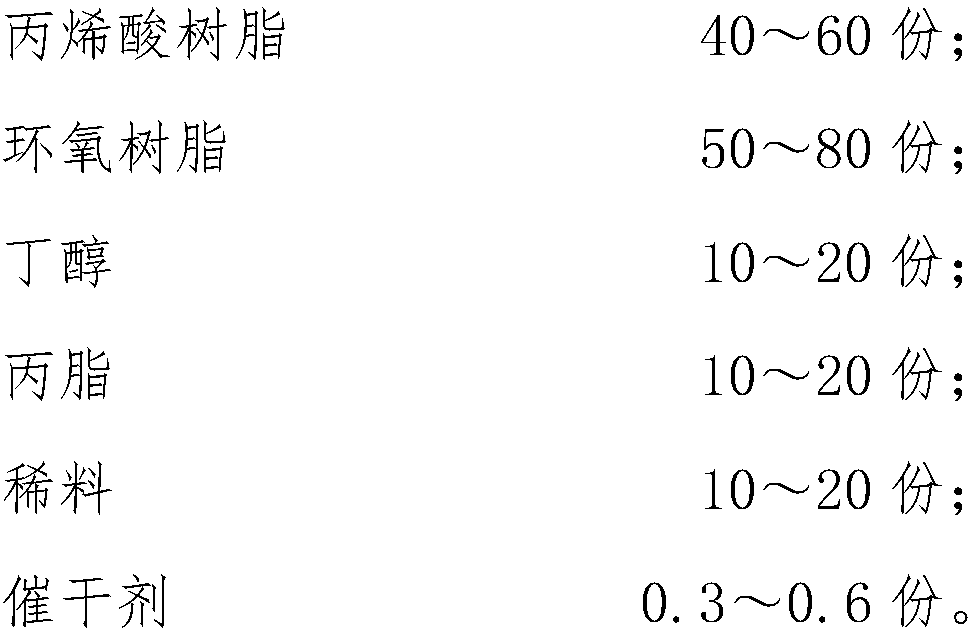

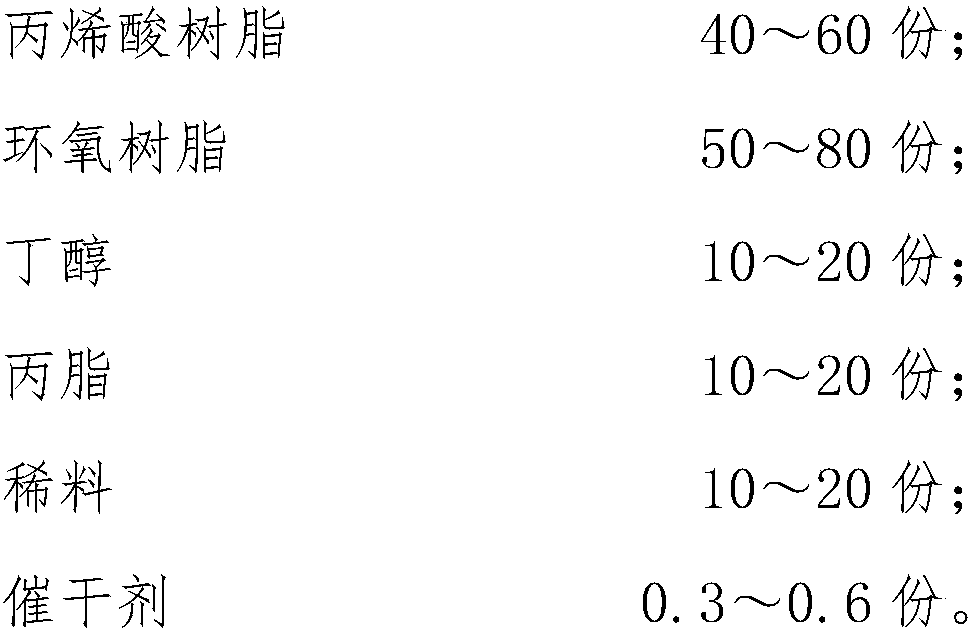

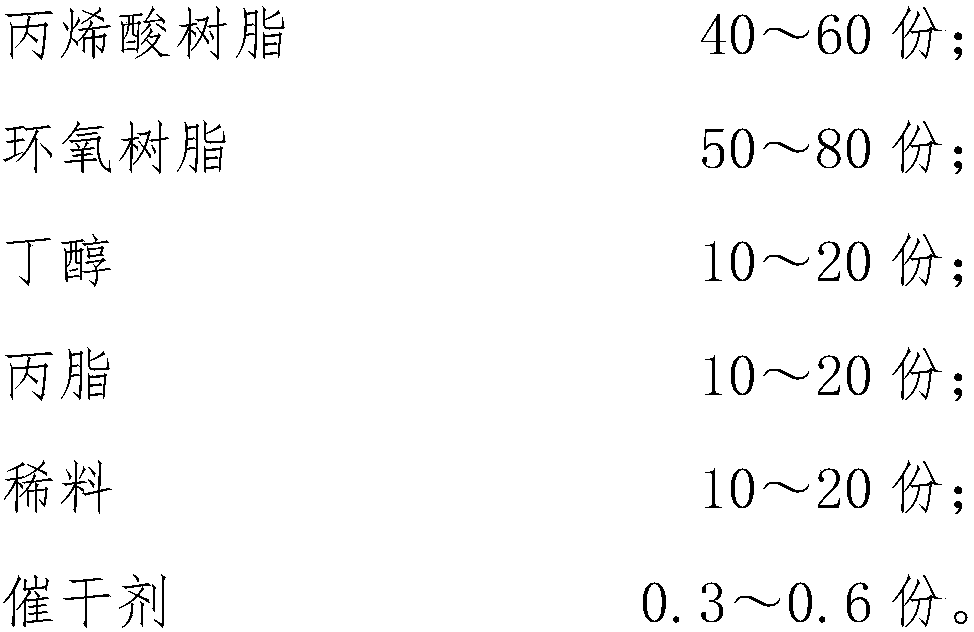

[0027] The invention proposes a special protective paint for highway anti-collision guardrails and a preparation method thereof. The protective paint consists of the following components by weight: 40-60 parts of acrylic resin, 50-80 parts of epoxy resin, 10-20 parts of butanol 10-20 parts of acrylic fat, 10-20 parts of thinner, 0.3-0.6 parts...

Embodiment 1

[0030] (1) Weigh 45 parts of acrylic resin, 55 parts of epoxy resin, 12 parts of butanol, 11 parts of acrylic resin, 15 parts of thinner, and 0.3 part of drier, and mix acrylic resin, epoxy resin, butanol, acrylic resin, The thinner and drier are put into the reaction kettle for stirring treatment, the stirring time is 1h, and the rotation speed is 330 rpm;

[0031] (2) Add the dispersant and the antifoaming agent into the step 1, and carry out the stirring treatment again, the stirring time is 1.5 h, the rotating speed is 450 rpm, and the finished product is obtained.

Embodiment 2

[0033] (1) Weigh 50 parts of acrylic resin, 61 parts of epoxy resin, 15 parts of butanol, 13 parts of acrylic resin, 12 parts of thinner, and 0.4 part of drier, and mix acrylic resin, epoxy resin, butanol, acrylic resin, The thinner and drier are put into the reaction kettle for stirring treatment, the stirring time is 1h, and the rotation speed is 400 rpm;

[0034] (2) Add the dispersant and the antifoaming agent into the step 1, and carry out the stirring treatment again, the stirring time is 1.5 h, and the rotation speed is 480 rpm to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com