Polyheterocyclic cyanuric chloride antioxidant corrosion inhibitor as well as preparation method and application thereof

An anti-oxidant corrosion inhibitor, cyanuric chloride technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of poor solubility, accelerated corrosion, high cost, and achieve good oxygen resistance. Corrosion effect, good corrosion inhibition performance, effect of delaying pipe corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of polyheterocyclic cyanuric chloride anti-oxidant corrosion inhibitor, comprises the following steps:

[0021] (1) Add 3.08g of cyanuric chloride to a 250mL three-necked flask, and simultaneously add 30mL of acetone as a solvent, and mix well;

[0022] (2) Dissolve 4g of pyridine in 50mL of acetone, and slowly add it dropwise to the result of step (1) at a rate of 15mL / min in an ice-water bath, continue the reaction for 2h after the dropwise addition, and then raise the temperature to 30°C Continue to react for 4 hours, then raise the temperature to 70°C for 8 hours under reflux, cool to room temperature and filter to obtain the precipitate, wash the precipitate with 50 mL of absolute ethanol for 3 times, and dry at 50°C for 6 hours to obtain a white solid product, namely polyheterocyclic trimeric chloride Cyanide antioxidant corrosion inhibitor.

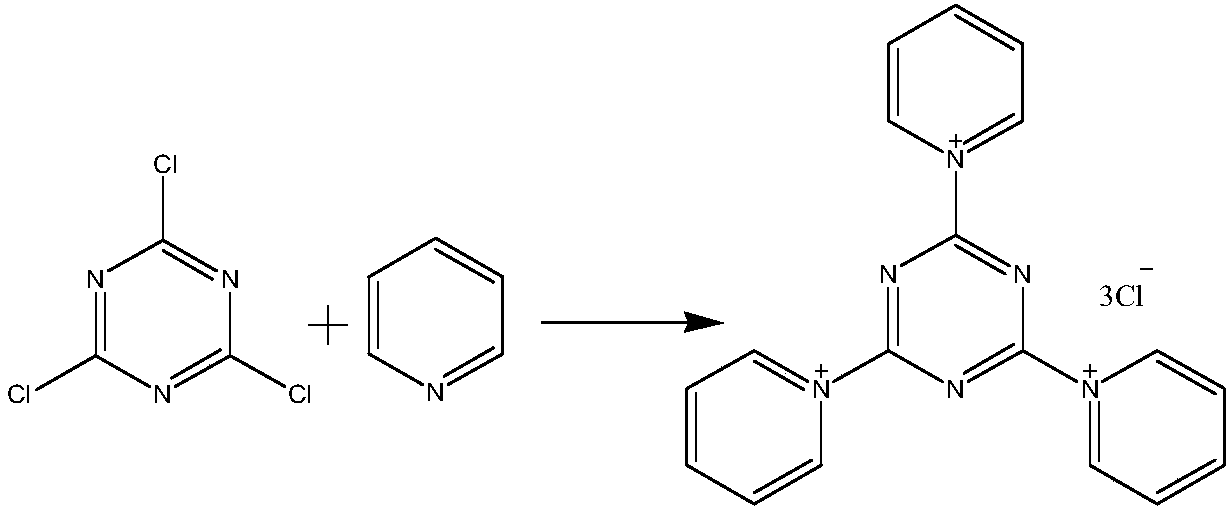

[0023] The above reaction formula is as follows:

[0024]

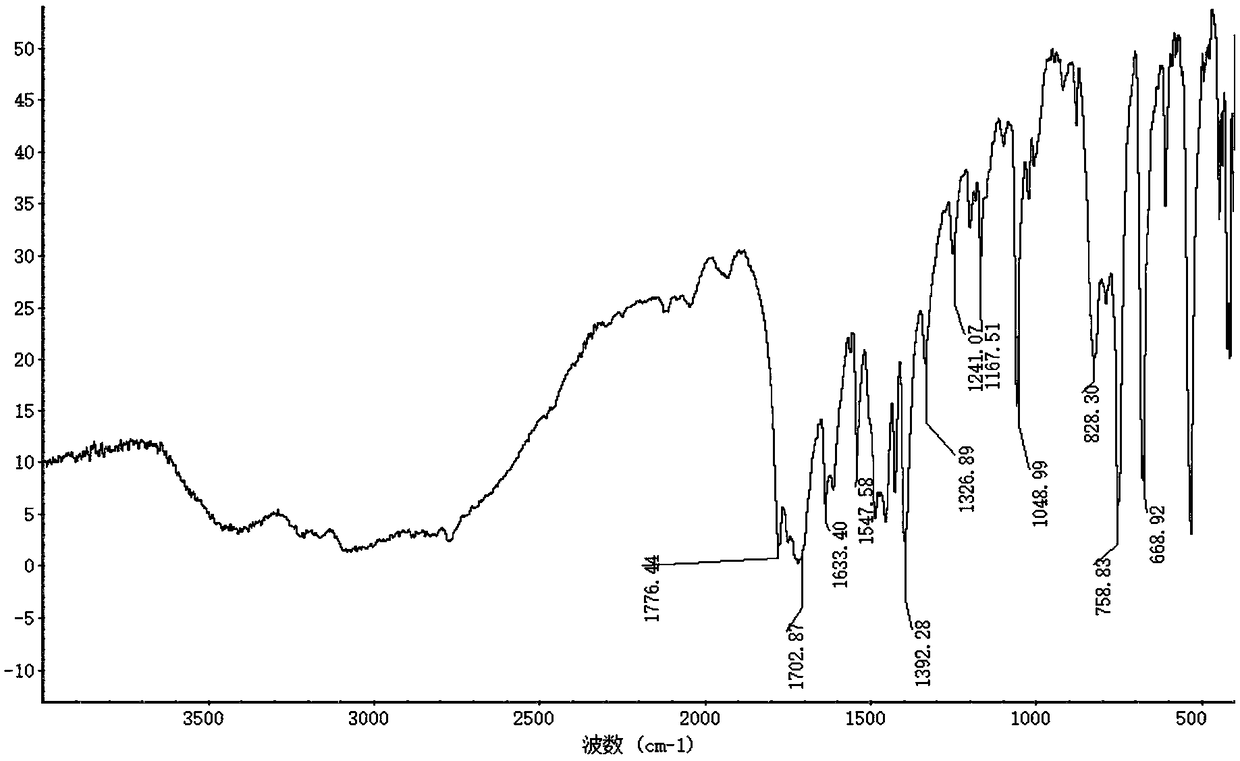

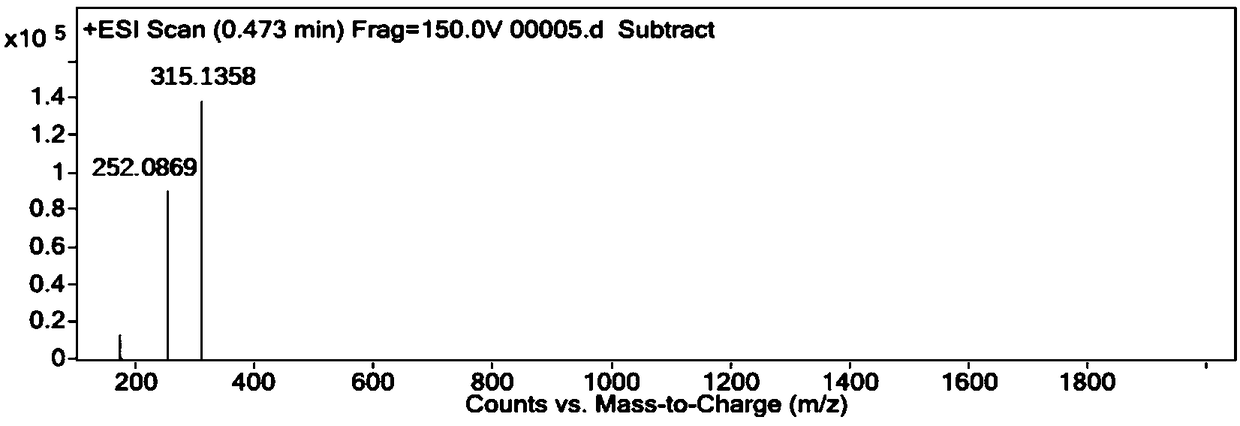

[0025] The resulting product is dete...

Embodiment 2

[0028] A preparation method of polyheterocyclic cyanuric chloride anti-oxidant corrosion inhibitor, comprises the following steps:

[0029] (1) Add 3.08g of cyanuric chloride to a 250mL three-necked flask, and simultaneously add 30mL of ethyl acetate as a solvent, and mix well;

[0030] (2) Dissolve 6.5g of quinoline in 50mL of acetone, slowly add it dropwise to the resultant of step (1) at a rate of 15mL / min under ice-water bath conditions, continue to react for 2h after the dropwise addition, and then heat up to Continue the reaction at 45°C for 4h, then raise the temperature to 80°C for 8h under reflux, cool to room temperature and filter to obtain the precipitate, wash the precipitate with 50mL of absolute ethanol for 3 times, and dry at 50°C for 6h to obtain a white solid product, polyheterocyclic three Polycyanogen chloride anti-oxidant corrosion inhibitor.

[0031] The above reaction formula is as follows:

[0032]

Embodiment 3

[0034] A preparation method of polyheterocyclic cyanuric chloride anti-oxidant corrosion inhibitor, comprises the following steps:

[0035] (1) Add 3.08g of cyanuric chloride to a 250mL three-necked flask, and simultaneously add 30mL of ethyl acetate as a solvent, and mix well;

[0036] (2) Dissolve 4.4g of quinoline in 50mL of acetone, slowly add it dropwise to the resultant of step (1) at a speed of 17mL / min under ice-water bath conditions, continue to react for 3h after the dropwise addition, and then heat up to Continue to react at 30°C for 6h, then raise the temperature to 80°C for reflux reaction for 12h, cool to room temperature and filter to obtain a precipitate, wash the precipitate with 50mL of absolute ethanol three times, and dry at 50°C for 6h to obtain a white solid product, polyheterocyclic three Polycyanogen chloride anti-oxidant corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com