Electrolytic copper foil antioxidant

An anti-oxidant, electrolytic copper foil technology, applied in the electrolysis process, electroforming, etc., can solve the problems of not being environmentally friendly, containing heavy metals, and copper is easily oxidized, so as to achieve the effect of eliminating water pollution, preventing oxidation, and improving roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

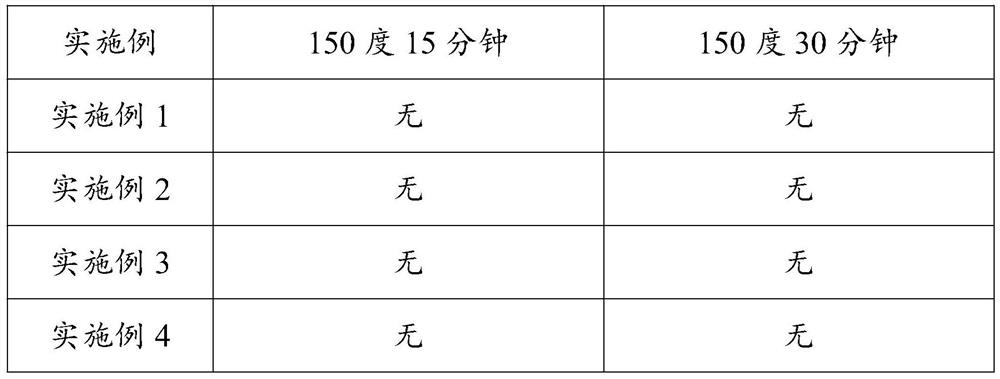

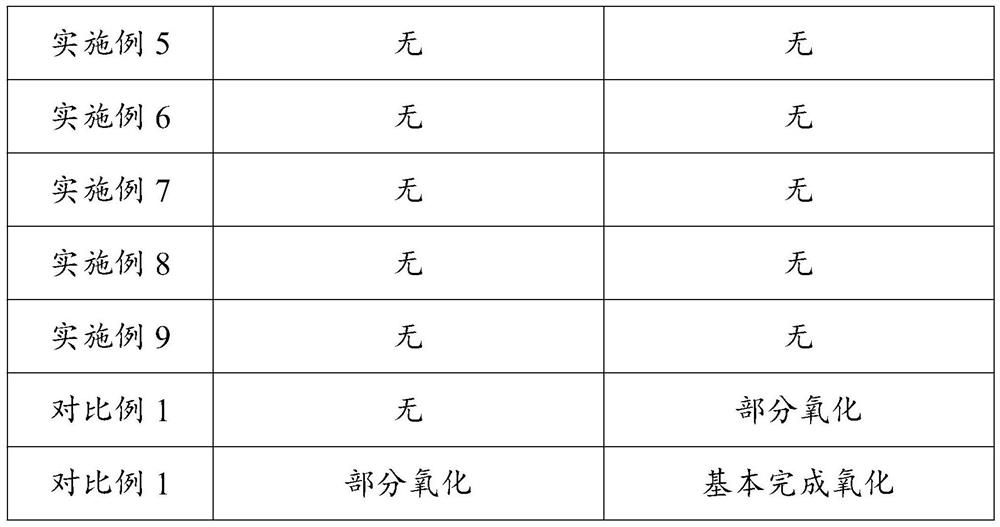

Examples

Embodiment 1

[0019] Stir and mix 10 g of citric acid, 10 g of sodium metaaluminate, 1 g of fatty alcohol polyoxyethylene ether, 9 g of sodium dodecylbenzenesulfonate, and 10 g of glucose to obtain an antioxidant.

Embodiment 2

[0021] Stir and mix 1kg of tartaric acid, 1kg of sodium tungstate, 100g of fatty alcohol polyoxyethylene ether, 900g of octylphenol polyoxyethylene ether, and 1kg of maltose to obtain an antioxidant.

Embodiment 3

[0023] Stir and mix 10 g of citric acid, 10 g of 3-aminopropyltriethoxysilane, 1 g of polyethylene glycol, 9 g of propylene glycol block polyether, and 10 g of glucose to obtain an antioxidant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com