Bionic antioxidant polypropylene material and preparation method thereof

A polypropylene material and anti-oxidation technology, applied in the field of biomimetic anti-oxidation polypropylene material and its preparation, can solve the problems of unsatisfactory product effect, large environmental impact and high preparation cost, and achieve good anti-oxidation effect, Simple preparation process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

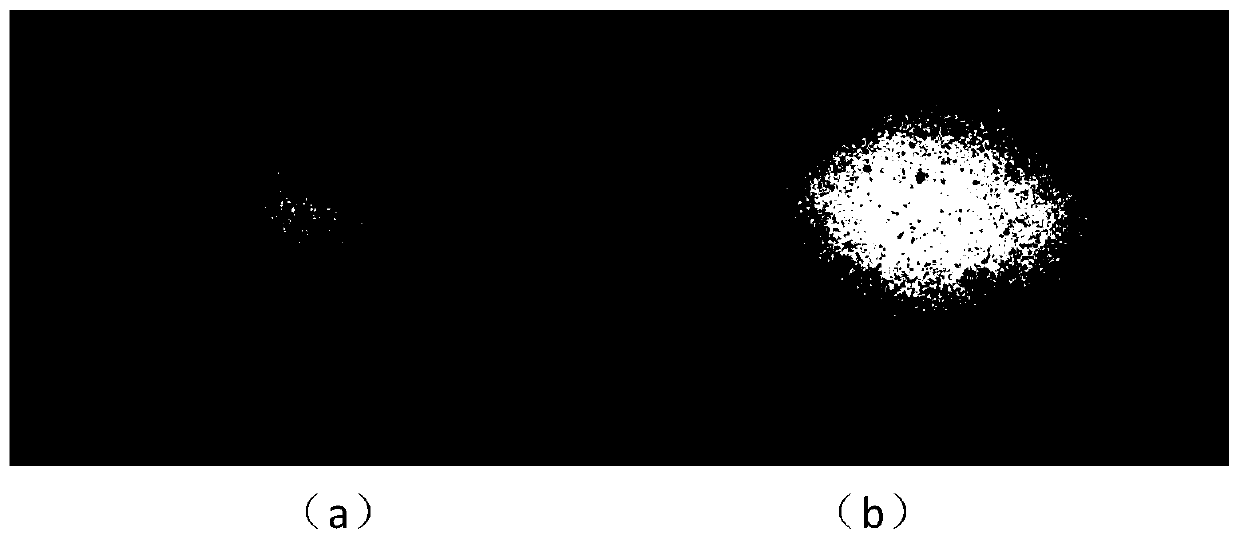

[0039] Step 1) Preparation of the melanin particles: A. Using tyrosine solution as raw material, adding the tyrosine solution into a buffer solution with a pH value of 7.8-8.2, heating to a reaction temperature of 70-75°C, Then adjust pH to 9~10 with alkali solution, cool to 50~60 DEG C, obtain tyrosine reaction solution; B, tyrosinase is dissolved in the buffer solution identical with step A, then with step A described The tyrosine reaction solution was stirred and mixed for 5-10 minutes, cooled to room temperature and then reacted for 12-24 hours, and finally freeze-dried to obtain melanin particles; the buffer solution was a phosphate buffer solution, and the pH of the buffer solution was controlled to be 8. The alkali solution is sodium hydroxide solution or potassium hydroxide solution.

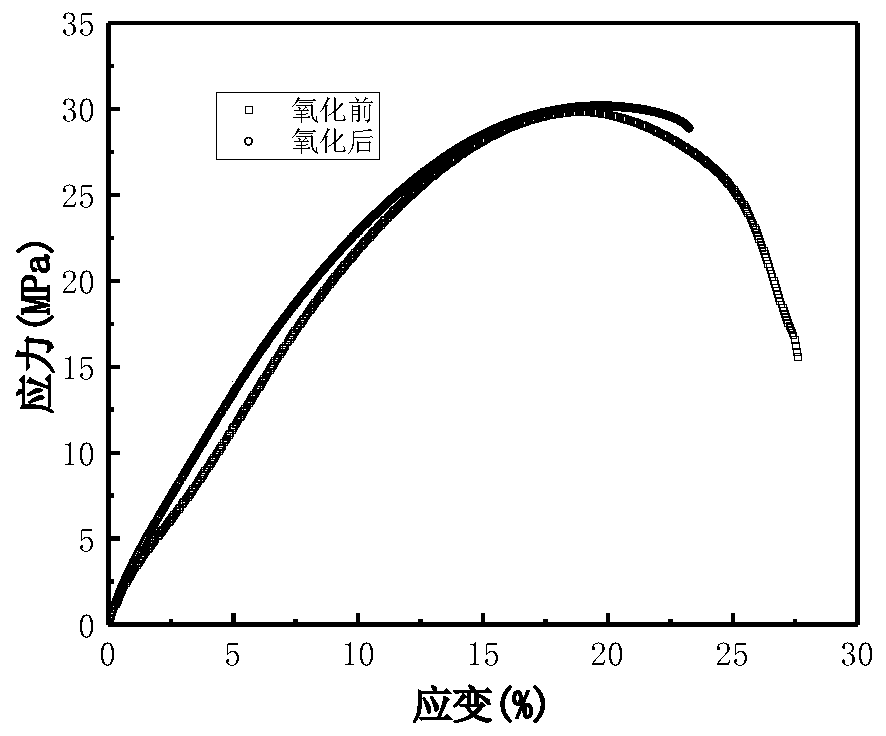

[0040] Step 2) The preparation of the polypropylene particles: (1) After fully mixing the polypropylene matrix and the melanin particles or polydopamine particles according to the mass r...

Embodiment 1

[0043] Take an ammonia solution with a mass ratio concentration of 28%-30%, mix it with ethanol and water at a volume ratio of 1:12.5 and 1:25, and place it in a reaction device, heat it at 40°C and gently stir and mix to obtain a mixed solution of ethanolamine Dissolving dopamine in a small amount of water, injecting it into the ethanolamine mixed solution, and reacting, controlling the reaction time to be 12 hours, centrifuging the obtained product for 15 minutes at 15,000 rpm, washing, and freeze-drying to obtain polydopamine particles.

[0044] Mix polypropylene with the polydopamine particles prepared above in a mass ratio of 100:0.5, add dropwise paraffin wax with a mass concentration ratio of 0.1%, stir in an electric mixer at high speed for 5 minutes, and add the obtained mixture into an extruder, Control the temperature of each section of the extruder from the feed to the head: 160°C, 180°C, 200°C, 200°C, control the screw speed of the extruder device to 50rpm, control...

Embodiment 2

[0046] Take an ammonia solution with a mass ratio concentration of 28%-30%, mix it with ethanol and water at a volume ratio of 1:12.5 and 1:25, and stir gently at 40°C. Dissolve dopamine in a small amount of water, inject ethanolamine mixed solution, and react for 12 hours. The product was centrifuged at 15000 rpm for 15 minutes, washed and freeze-dried to obtain polydopamine particles.

[0047] The polypropylene and the prepared polydopamine particles were mixed at a mass ratio of 100:0.5, 0.1% paraffin was added dropwise, and stirred in an electric mixer at high speed for 5 minutes. Add the mixture into the extruder, control the extruder from the feed to the machine head: 160°C, 180°C, 200°C, 200°C, that is, control the temperature range of the four zones of the extruder and the temperature of the fourth zone is the same Control at 200°C, control the screw speed of the extrusion device to 50rpm, control the ultrasonic frequency of the ultrasonic device to 15kHz, and the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com