Preparation method of multistage-channel carbon electrode material

A porous carbon electrode and carbon material technology, which is applied in the field of electrode materials, can solve the problems of rapid specific capacity decay and limit the free diffusion of electrolyte ions, etc., to facilitate rapid migration, solve the problem of high current charging and discharging, and enrich the pore size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

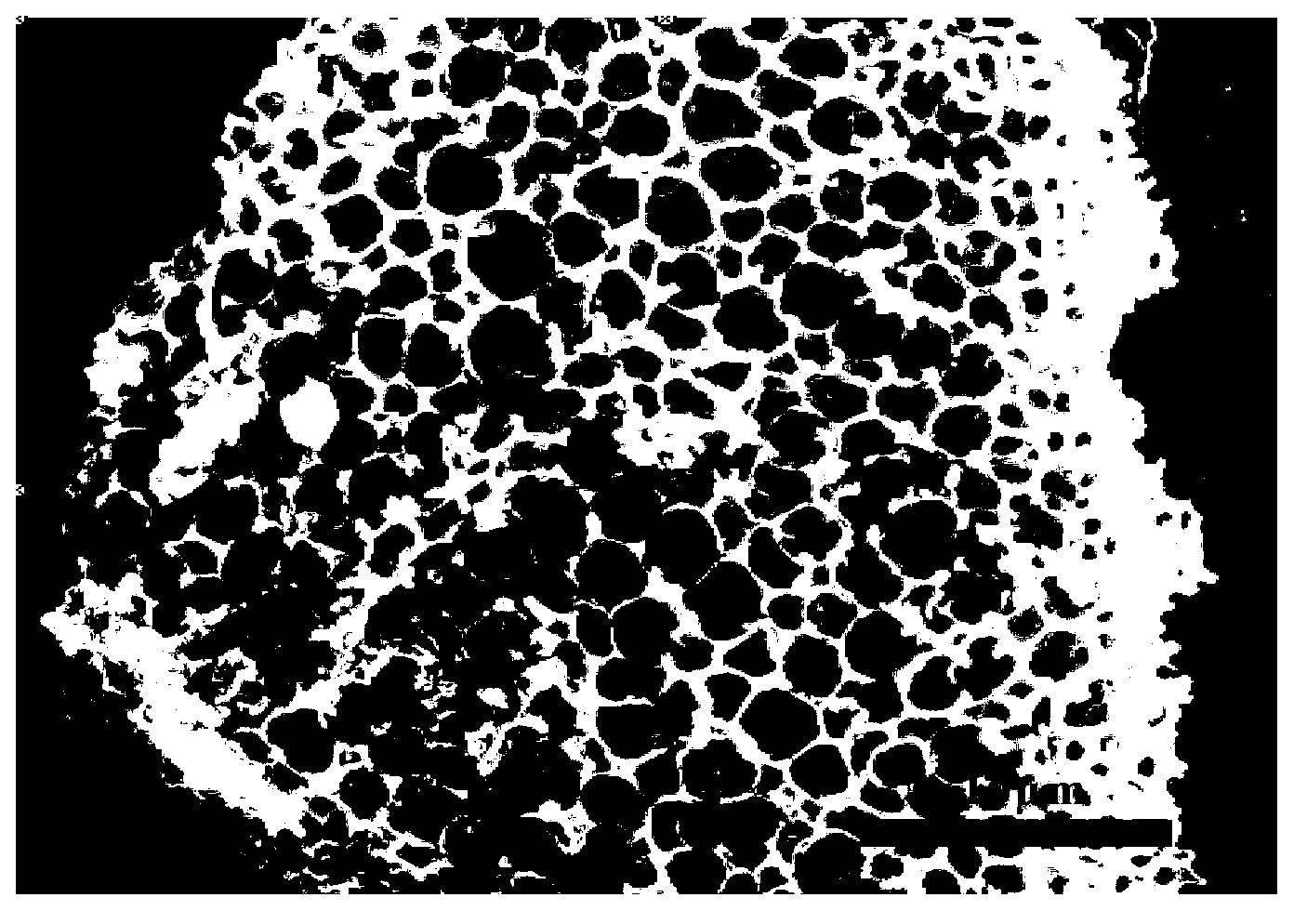

[0019] Clean Artemia egg shells, ball mill them for 2 hours, and then use HCl with a concentration of 6mol / L and HCl with a concentration of 8mol / L, respectively. 2 SO 4 , 6mol / L HNO 3 , 2mol / L KOH soaking pretreatment, soaking time is 6h for each substance, and drying to remove water. Calcinate the treated eggshell in an inert atmosphere, raise the temperature to 250°C at a rate of 1°C / min, keep it for 2 hours, then raise the rate of temperature rise to 500°C at a rate of 1°C / min and keep it for 1 hour. HNO 3 Ultrasonic treatment for 1 hour, the ultrasonic frequency is 40KHz, and the power is 30W. Then soak in 6mol / L HCl for 12h, wash to neutral, and dry to obtain a multi-level porous carbon material. The resulting material was characterized under SEM as figure 1 As shown, the hierarchical pore structure of carbon materials can be observed.

[0020] Grind the carbon material into powder, take 80 mg of carbon material, 15 mg of acetylene black, and 5 mg of PTFE emulsion ...

Embodiment 2

[0024] Clean Artemia egg shells, ball mill them for 7 hours, and then use HCl with a concentration of 9mol / L and HCl with a concentration of 13mol / L, respectively. 2 SO 4 , 10mol / L of HNO 3 , 4mol / L KOH soaking pretreatment, soaking time is 27h for each substance, and dry to remove water. Calcinate the above-mentioned treated Artemia eggshells in an inert atmosphere, raise the temperature to 300°C at a rate of 3°C / min, keep it for 7h, then raise the temperature to 750°C at a rate of 5.5°C / min and heat it for 24.5h, then HNO at 10mol / L 3 Ultrasonic treatment for 5.5 hours, the ultrasonic frequency is 40KHz, and the power is 40W. Then soak in 9mol / L HCl for 18h, wash until neutral, and dry to obtain a multi-level porous carbon material.

[0025] Grind the carbon material into powder, take 80 mg of carbon material, 15 mg of acetylene black, 5 mg of PTFE emulsion with a mass fraction of 60%, mix them uniformly with ethanol ultrasonically, heat in a water bath at 65°C until it ...

Embodiment 3

[0029] Clean Artemia egg shells, ball mill for 12 hours, and then use 12mol / L HCl, 18mol / L H 2 SO 4 , 14mol / L HNO 3 And 6mol / L KOH soaking pretreatment, the soaking time is 48h for each substance, and dry to remove water. Calcinate the above-mentioned treated Artemia egg shells in an inert atmosphere, raise the temperature to 300°C at a rate of 5°C / min, keep it for 10h, and then raise the rate of temperature rise to 1000°C at a rate of 10°C / min and keep it for 48h. / L HNO 3 During ultrasonic treatment for 10 hours, the ultrasonic frequency is 40KHz and the power is 50W. Then soak in 9mol / L HCl for 24 hours, wash to neutrality, and dry to obtain a multi-level porous carbon material.

[0030] Grind the carbon material into powder, take 80 mg of carbon material, 15 mg of acetylene black, 5 mg of PTFE emulsion with a mass fraction of 60%, mix them uniformly with ethanol ultrasonically, heat in a water bath at 65°C until it becomes muddy, and then spread 5 mg of mud evenly on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com