A kind of preparation method of carbon hollow microspheres with asymmetric structure

An asymmetric structure, microsphere technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of low purity of carbon hollow spheres, less research on the mechanism of catalyst action, and increase the cost of carbon hollow spheres. And the effect of controllable hollow rate, rich pore size distribution, and large liquid storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

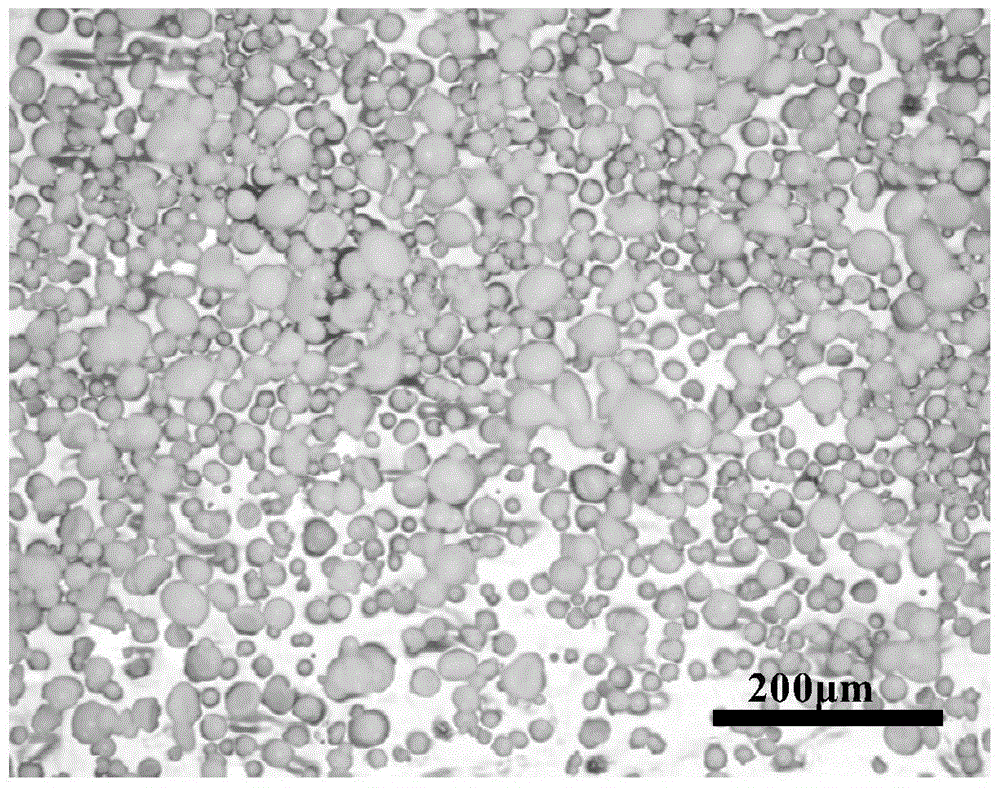

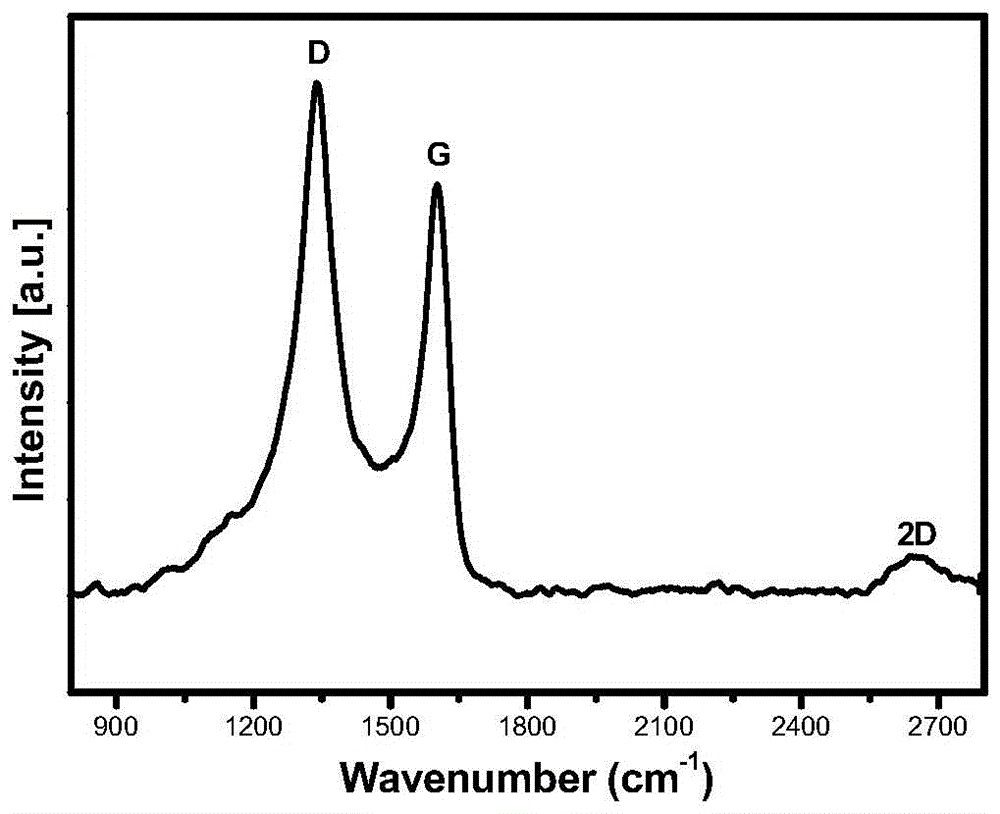

[0027] A method for preparing carbon hollow microspheres with an asymmetric structure, using the following steps:

[0028] Step 1: Preparation of carbon hollow microsphere precursor slurry

[0029] The carbon hollow microsphere precursor slurry is prepared from a solute and a solvent. The polymer is first added to the solvent, and the slurry is fully stirred and dissolved for degassing, and finally a slurry suitable for the preparation of the carbon hollow microsphere precursor is obtained. The added polymer is any one of cellulose acetate, polysulfone, polyethersulfone or polyvinylidene fluoride, and the solvent is any one of N-methylpyrrolidone, acetone, acetylacetone or dimethylacetamide. The mass ratio of solute and solvent is 10-40:90-60.

[0030] Step 2: Preparation of carbon hollow microsphere precursor

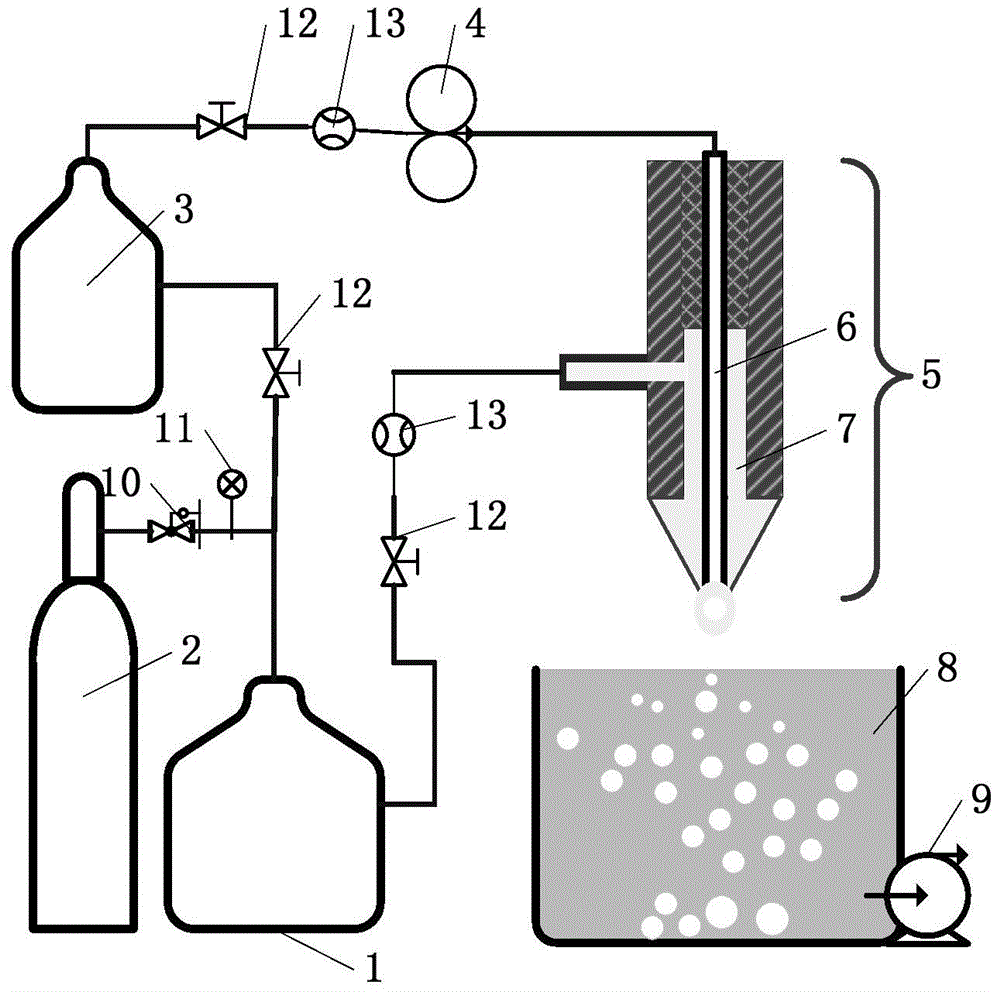

[0031] Carbon hollow microsphere precursors in figure 1 Prepared in the peristaltic pump assisted coaxial microfluidic system shown, the structure of the peristalti...

Embodiment 1

[0037] Step 1: Add 8g of polyethersulfone to 90g of NMP, stir to dissolve and mix evenly, then age and degas to obtain a slurry.

[0038] Step 2: Use deionized water as the non-solvent. The inner tube 6 of the coaxial nozzle has a diameter of 0.15 mm and the outer tube 7 of the coaxial nozzle has a diameter of 0.5 mm. The distance between the coaxial nozzle 5 and the non-solvent tank 8 is set to 10 mm. First open the compressed nitrogen drive pressure system: compressed nitrogen cylinder 2, pressure reducing valve 10, precision pressure gauge 11, screw valve 12, rotameter 13 to deliver the driving pressure within 0.1MP, by adjusting the non-solvent pipeline The rotary valve and the peristaltic pump speed (0.5 rev / min) make the non-solvent in the non-solvent tank 3 smoothly drop out in droplet shape. Then pour the slurry prepared in step 1 into the slurry tank 1, open the screw valve 12 on the slurry pipeline, and adjust the rotameter to reach the driving pressure within the r...

Embodiment 2

[0041] Step 1: Add 28g of polyethersulfone into 60g of NMP, stir to dissolve, mix evenly, age and degas to obtain a slurry.

[0042] Step 2: Use deionized water as a non-solvent. Choose a coaxial nozzle with a diameter of 0.5 mm in the inner tube 6 of the coaxial nozzle and a diameter of 1.2 mm in the outer tube 7 of the coaxial nozzle. Set the coaxial nozzle 5 and the non-solvent tank 8. The distance between them is 50mm. First open the compressed nitrogen drive pressure system: compressed nitrogen cylinder 2, pressure reducing valve 10, precision pressure gauge 11, screw valve 12, rotameter 13 to deliver the driving pressure within 0.1MP, by adjusting the non-solvent pipeline The rotary valve and the peristaltic pump speed (0.5 rev / min) make the non-solvent in the non-solvent tank 3 smoothly drop out in droplet shape. Then pour the slurry prepared in step 1 into the slurry tank 1, open the screw valve 12 on the slurry pipeline, and adjust the rotameter to reach the driving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com