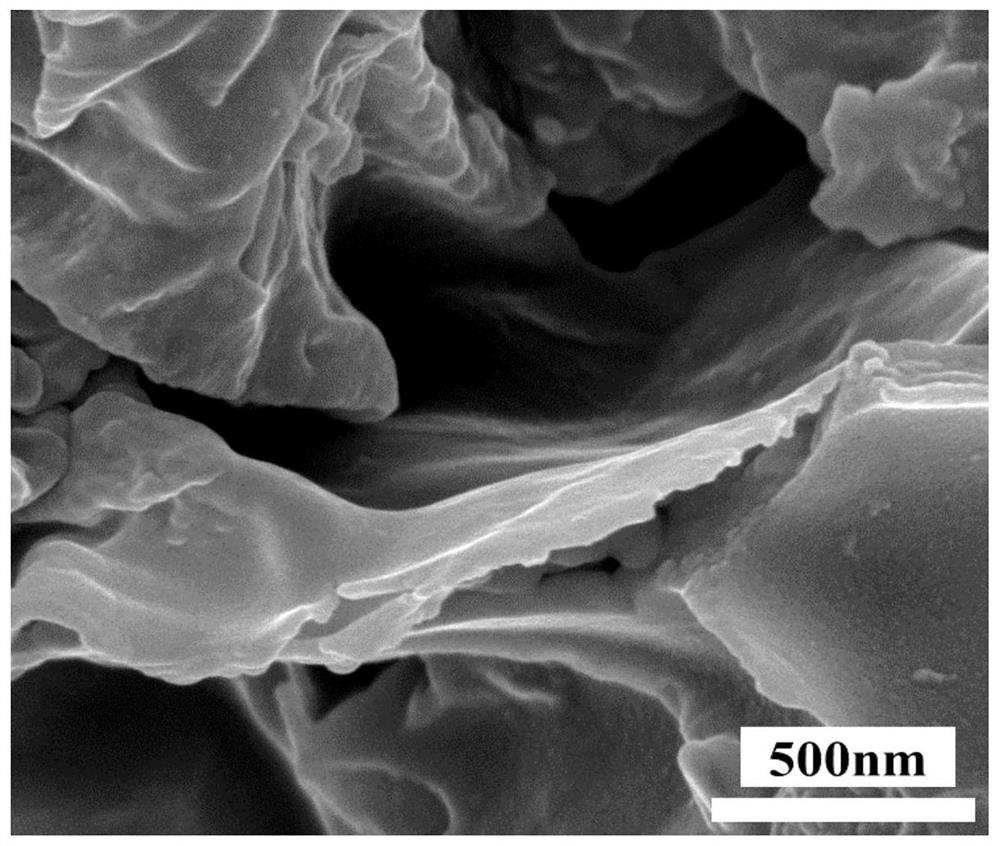

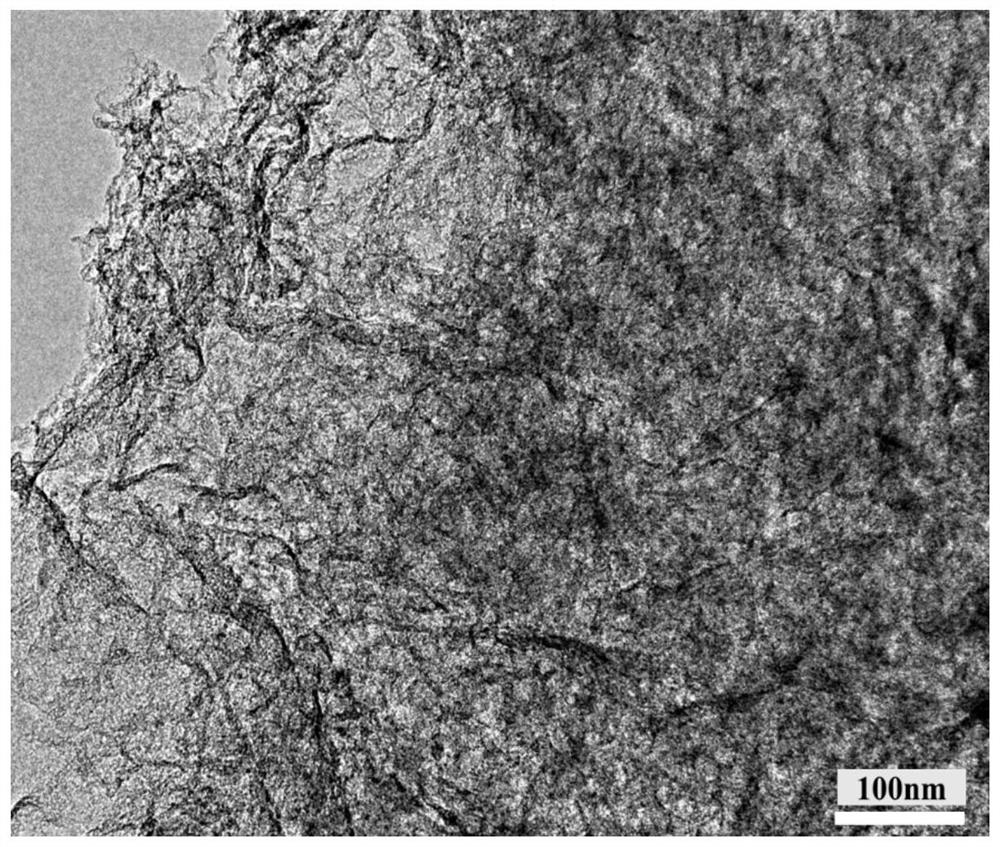

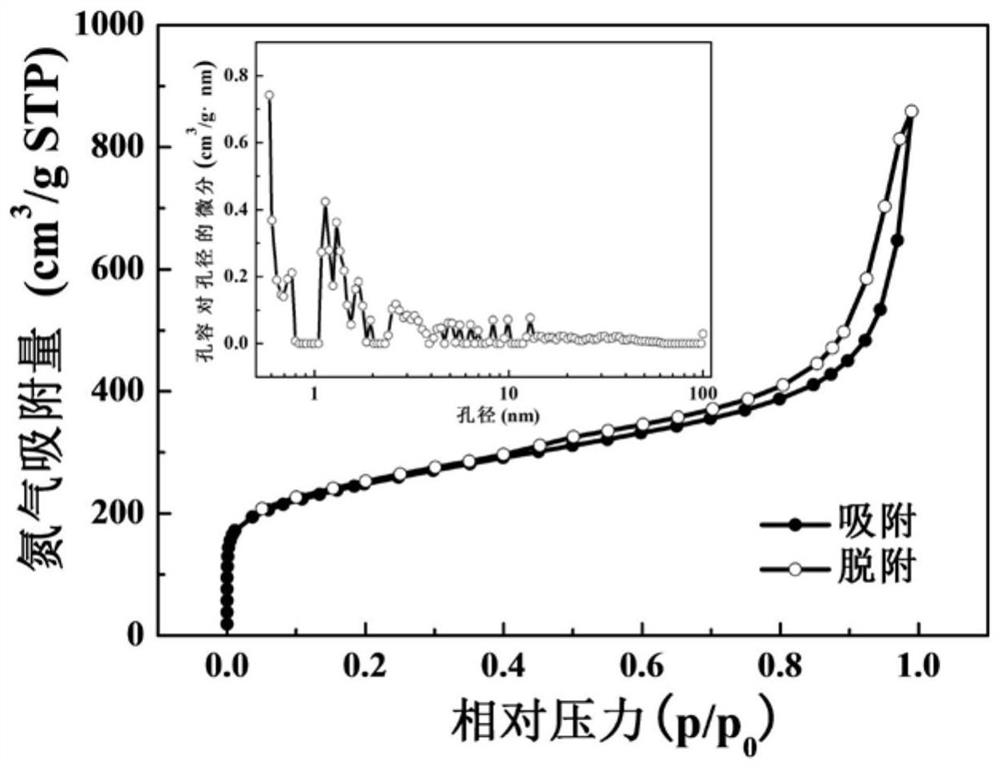

A silver-doped lignin porous carbon nanosheet and its preparation method and application in supercapacitor electrode materials

A technology of lignin and porous carbon, applied in hybrid capacitor electrodes, nano-carbon, chemical instruments and methods, etc., can solve the problems of single distribution of porous carbon pore structure, difficult to control the nitrogen content of products, complicated preparation process, etc., and achieve the preparation process. Simple and environmentally friendly, good application value, and the effect of reasonable pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 5 parts by mass of sodium lignosulfonate, 0.25 parts by mass of silver nitrate and 5 parts by mass of zinc oxalate solid powder were weighed into 500 parts by volume of water, heated and stirred at 50° C. for 30 min to prepare stable dispersion A. Take 50 parts by volume of dispersion liquid A, add 50 parts by volume of ethanol under stirring, and separate the precipitate after standing to obtain a silver / lignin / zinc oxalate complex. Then take 50 parts by volume of dispersion A, add the silver / lignin / zinc oxalate composite prepared above, stir for 20 minutes, add 50 parts by volume of ethanol, and separate the silver / lignin / zinc oxalate composite after standing. The above operation was repeated 6 times, and the precipitate was separated to obtain a layer-by-layer self-assembled composite silver / lignin / zinc oxalate composite.

[0064] The layer-by-layer self-assembled silver / lignin / zinc oxalate composite was placed in an inert atmosphere, carbonized at 650 °C for 3 h to ...

Embodiment 2

[0066] 5 parts by mass of magnesium lignosulfonate, 0.25 parts by mass of silver fluoride and 7.5 parts by mass of magnesium oxalate solid powder were weighed into 500 parts by volume of water, heated and stirred at 50° C. for 30 min to prepare stable dispersion A. Take 50 parts by volume of dispersion liquid A, add 50 parts by volume of ethanol under stirring, and separate the precipitate after standing to obtain a silver / lignin / magnesium oxalate complex. Then take 50 parts by volume of dispersion liquid A, add the silver / lignin / magnesium oxalate composite prepared above, stir for 20 minutes, add 50 parts by volume of ethanol, and separate the silver / lignin / magnesium oxalate composite after standing. The above operation was repeated 8 times, and the precipitate was separated to obtain a layer-by-layer self-assembled composite silver / lignin / magnesium oxalate composite.

[0067] The layer-by-layer self-assembled silver / lignin / magnesium oxalate composite was placed in an inert a...

Embodiment 3

[0069] 10 parts by mass of calcium lignosulfonate, 0.5 parts by mass of silver nitrate and 5 parts by mass of calcium oxalate solid powder were weighed into 500 parts by volume of water, heated and stirred at 50° C. for 30 min to prepare stable dispersion A. Take 50 parts by volume of a dispersion of calcium lignosulfonate, silver and calcium oxalate, add 50 parts by volume of ethanol under stirring, and separate the precipitate after standing to obtain a silver / lignin / calcium oxalate complex. Then take 50 parts by volume of dispersion A, add the silver / lignin / calcium oxalate composite prepared above, stir for 20 minutes, add 50 parts by volume of ethanol, and separate the silver / lignin / calcium oxalate composite after standing. The above operation was repeated 6 times, and the precipitate was separated to obtain a layer-by-layer self-assembled composite silver / lignin / calcium oxalate composite.

[0070] The layer-by-layer self-assembled silver / lignin / calcium oxalate composite w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com