Patents

Literature

244 results about "Oxalate salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxalate (IUPAC: ethanedioate) is the dianion with the formula C 2O2− 4, also written (COO)2− 2. Either name is often used for derivatives, such as salts of oxalic acid, for example sodium oxalate Na2C2O4, or dimethyl oxalate ((CH3)2C2O4). Oxalate also forms coordination compounds where it is sometimes abbreviated as ox.

Non-aqueous electrolytic solution

ActiveUS7255965B2Improve battery performanceGood SEIOrganic electrolyte cellsSecondary cellsHigh temperature storageLithium

The use of lithium bis(oxalate)borate (LiBOB) as an additive in a lithium secondary battery provides improved battery performance such as long life and high capacity retention after high temperature storage.

Owner:SHENZHEN CAPCHEM TECH CO LTD

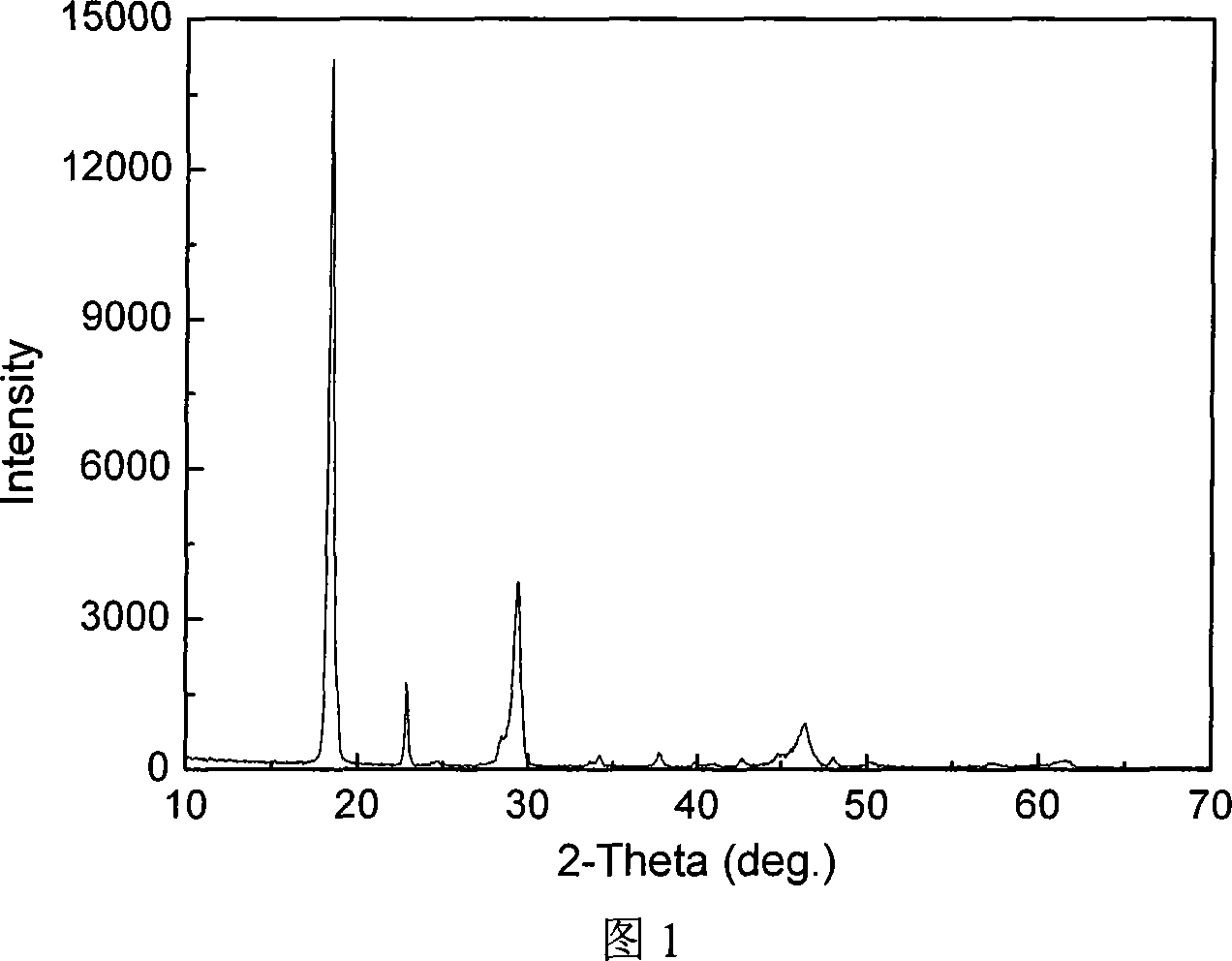

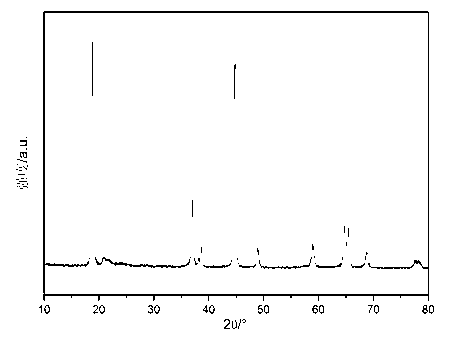

Method for preparing anode material of lithium ion battery in series of phosphate of olivine type

InactiveCN101049922AAchieve hybridEvenly distributedCell electrodesPhosphorus compoundsAluminium-ion batteryPhosphate

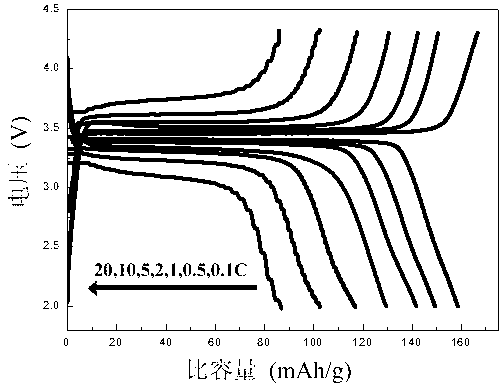

This invention relates to a method for preparing olivine-type phosphate-series lithium ion battery anode material. The method comprises: mixing one or more of ferrous salt solution, cobalt salt solution and manganese salt solution with oxalic acid or oxalate (precipitating agent) aqueous solution to obtain composite oxalate precursor, uniformly mixing with lithium source and phosphorus source by ball milling, and reacting in inert or weak-reductive atmosphere to obtain olivine-type phosphate-series lithium ion battery anode material. The method utilizes co-precipitation method for metal ion doping, and realizes molecular level uniform mixing among different ions. The obtained olivine-type phosphate-series lithium ion battery anode material has uniform chemical and physical compositions. The average particle size can be controlled within 0.3-10 mu.m. The first charge and discharge cycle specific capacity can reach 150 mAh / g at 0.1 C rate and room temperature. The livine-type phosphate-series lithium ion battery anode material has such advantages as high cycle performance and high charge / discharge performance.

Owner:CENT SOUTH UNIV

Non-aqueous electrolytic solution

ActiveUS20060240327A1Improve battery performanceGood SEIOrganic electrolyte cellsSecondary cellsLithiumHigh temperature storage

The use of lithium bis(oxalate)borate (LiBOB) as an additive in a lithium secondary battery provides improved battery performance such as long life and high capacity retention after high temperature storage.

Owner:SHENZHEN CAPCHEM TECH CO LTD

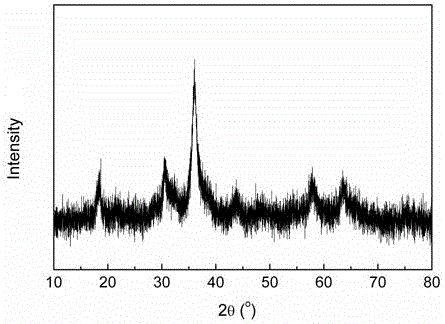

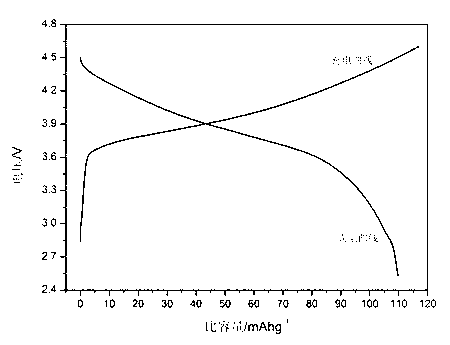

Method for preparing lithium-enriched lithium manganese oxide solid solution cathode material

ActiveCN102544475AFlexible adjustment ratioHomogeneous coprecipitationCell electrodesOXALIC ACID DIHYDRATENickel salt

The invention relates to a method for preparing a lithium-enriched lithium manganese oxide solid solution cathode material. The method comprises the following steps of: adding a mixed aqueous solution of nickel salt, cobalt salt and manganese salt into an oxalic acid or oxalate aqueous solution by an oxalate coprecipitation high-temperature solid state method, and stirring and reacting to generate nickel, cobalt and manganese oxalate coprecipitation; performing solid and liquid separation, washing and drying to obtain a nickel, cobalt and manganese oxalate precursor; and mixing and grinding the precursor and lithium salt, drying, baking at high temperature in an air atmosphere, and thus obtaining the lithium-enriched lithium manganese oxide solid solution cathode material. During preparation of the precursor, the proportion of the nickel salt, the cobalt salt and the manganese salt is adjusted, so that the constituents of the lithium-enriched lithium manganese oxide solid solution cathode material can be adjusted flexibly. The preparation method is suitable for large-scale, economic, stable and reliable production of the lithium-enriched lithium manganese oxide solid solution cathode material, has obvious advantages, and is high in practical value.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Normal temperature formaldehyde removal catalysis material

InactiveCN104741130ALow costEfficient enrichmentDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalCatalytic oxidation

The invention relates to a formula and a corresponding preparation technology of a normal temperature formaldehyde removal catalysis material, and belongs to the technical fields of normal temperature adsorption catalysis and air pollution treatment. The catalysis material is prepared by adopting a one-step co-precipitation process or a step-by-step dipping process to load active components with granular, cylindrical, spherical or honeycomb high-specific surface area shell activated carbon as a carrier, one or more non-noble metal salts as main active components, such as nitrate, sulfate or chloride of manganese, iron, cobalt, nickel, copper, zinc, lanthanum or cerium, one or more alkali metal / alkaline earth metal salts as an inorganic additive, such as oxalate, nitrate, sulfate, acetate, carbonate and bicarbonate of sodium, potassium, magnesium, calcium, and ethylenediamine tetracetic acid / ethylenediamine tetraacetic acid salt, basic amino acid, polyamide monomer and polyurethane monomer as a nitrogen-containing organic additive. The normal temperature formaldehyde removal catalysis material has the characteristics of rapid capture, high efficiency catalytic oxidation and long working cycle, and can meet requirements of long-time effective removal of formaldehyde in indoor real environment.

Owner:江苏瑞丰科技实业有限公司

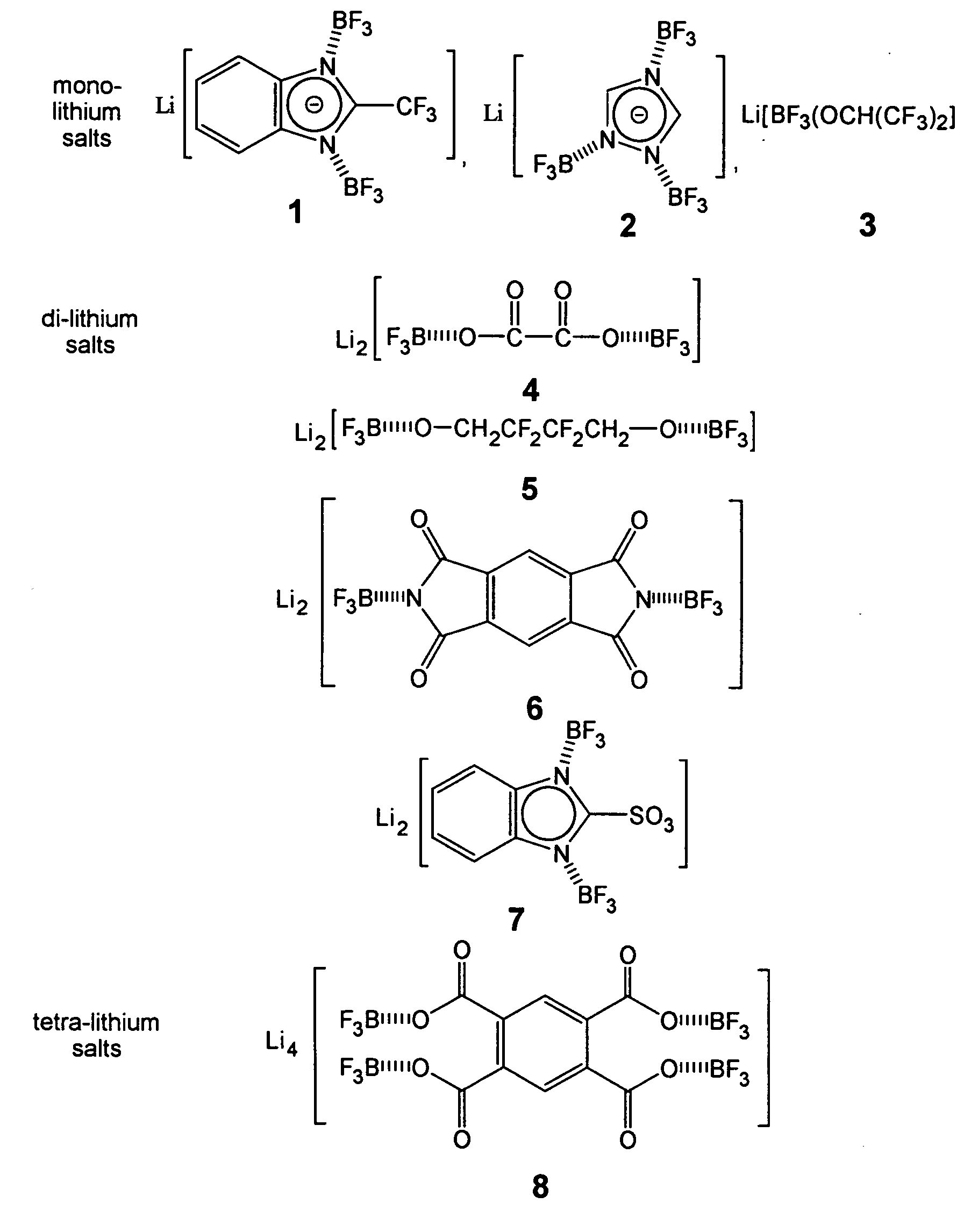

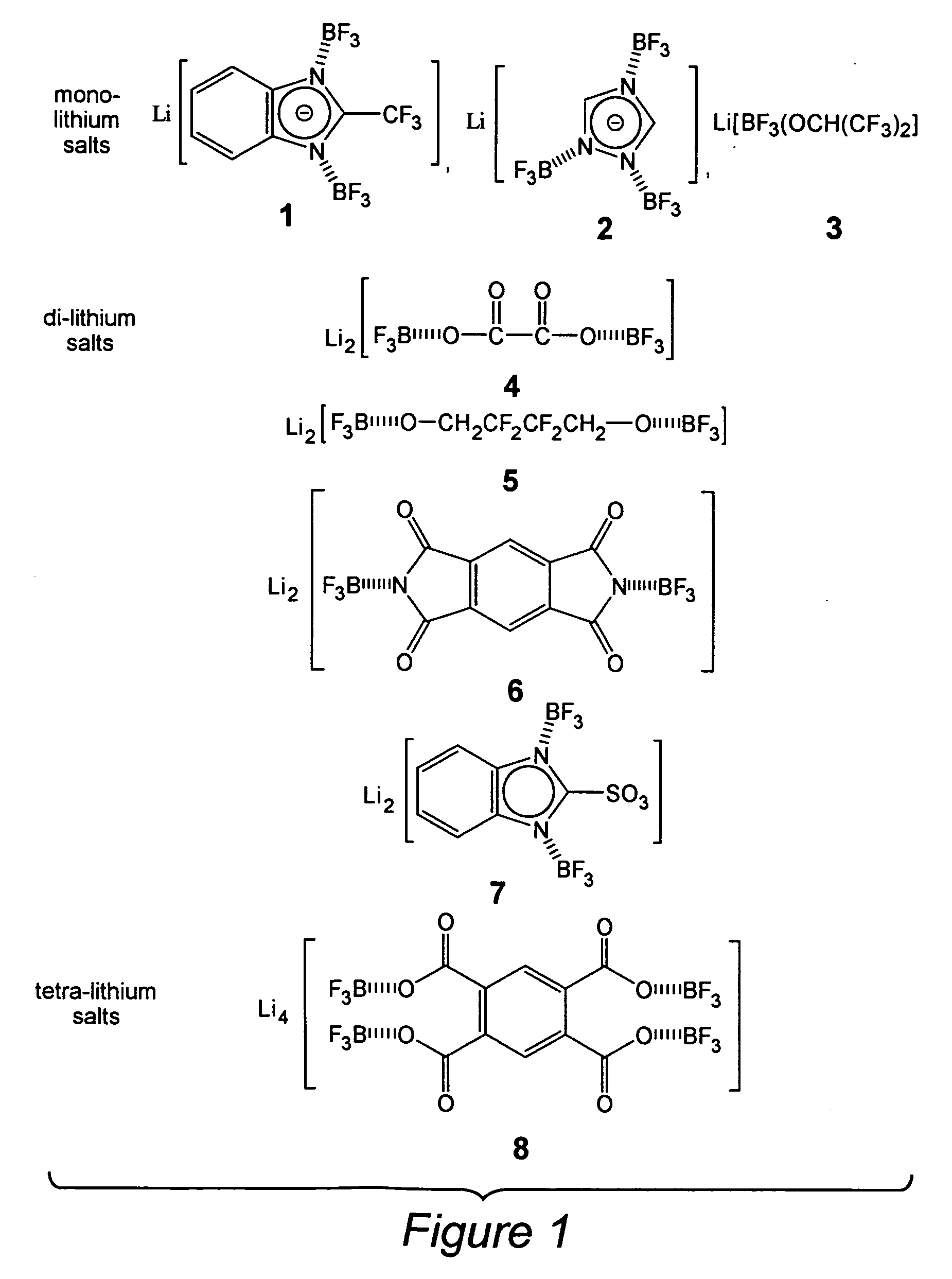

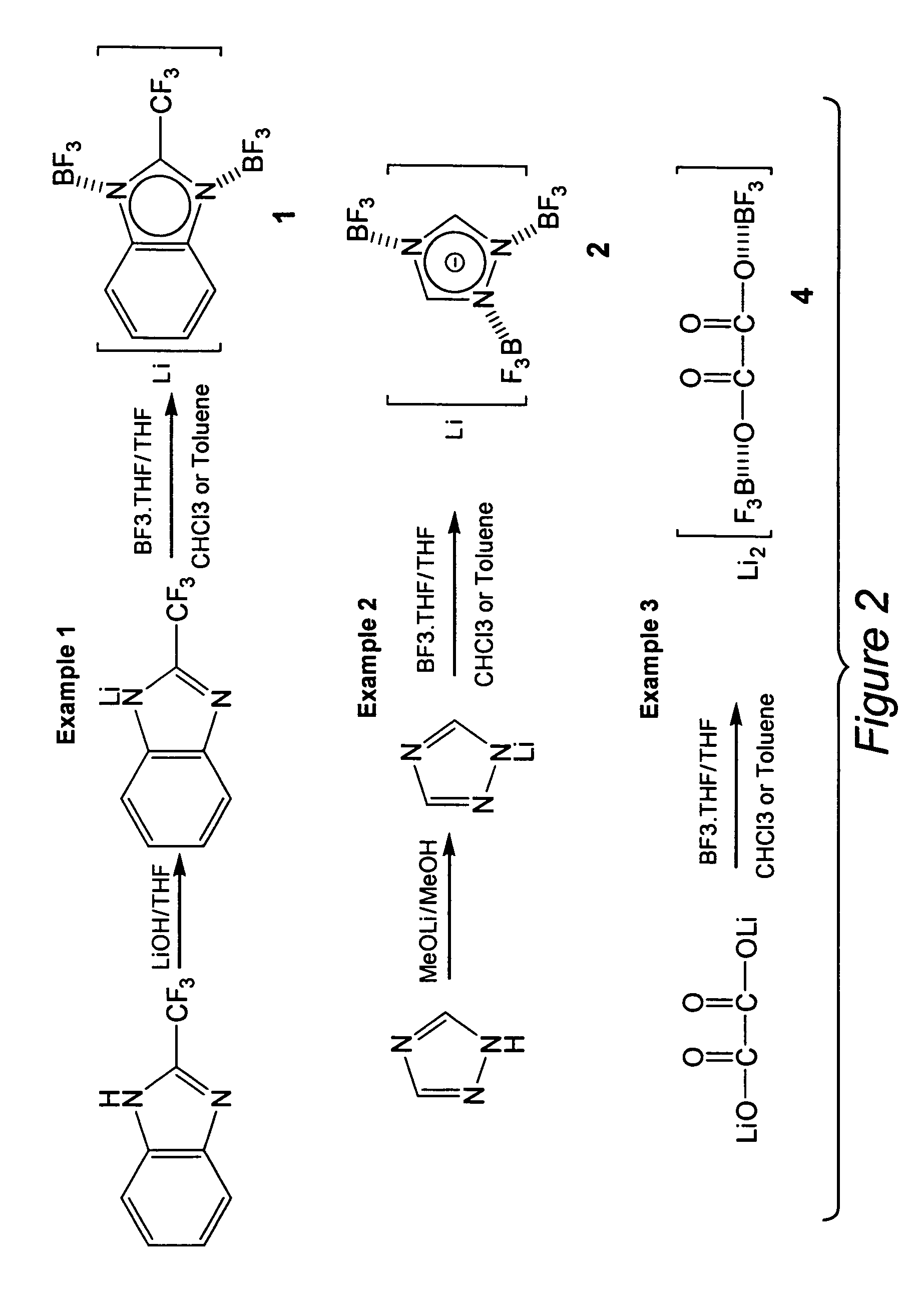

Organic lithium salt electrolytes having enhanced safety for rechargeable batteries and methods of making the same

InactiveUS20060068295A1Improve propertiesImprove thermal stabilityAlkaline accumulatorsOrganic electrolyte cellsProtonationCarboxylic salt

Organic lithium salts suitable for use in electrolytes for primary or secondary rechargeable batteries include de-localized bulky anions over Lewis acid fragments, typically BF3, and organic moieties. The organic moieties may be, for example, anions derived from fused nitrogen heterocycles (e.g. benzeneimidate, benzitriazolate and the like); multi carboxylates (e.g. oxalate, 1,2,4,5-benzenetetracarboxylate and the like), and pyromellitic diimidate. The organic lithium salts of the invention have the general formula: Liq[Org(MXn)m], in which Org represents the organic moieties and MXn represents an organic or inorganic boron, aluminum or phosphorous containing Lewis acid. The organic lithium salts are conveniently prepared by reacting an organic compound having at least one de-protonation group selected from NH, OH, SH or COOH with an inorganic or organic lithium compound to generate an organic lithium processor salt, and thereafter bringing the organic lithium processor salt into contact with an inorganic or organic Lewis acid to obtain the organic lithium product salt.

Owner:SKC POWER TECH

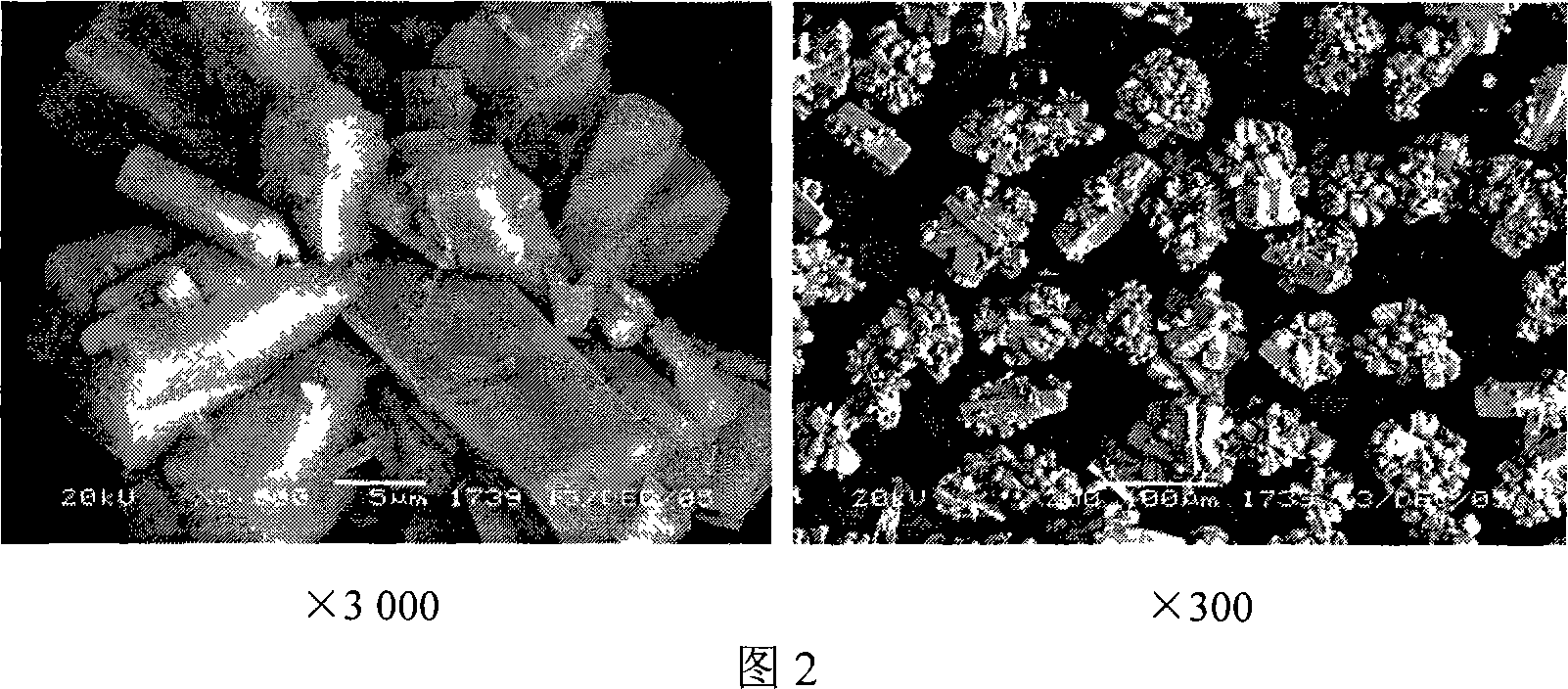

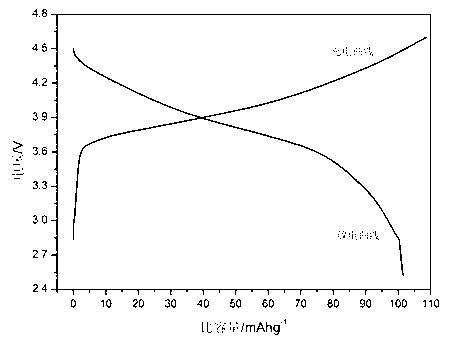

Oxide solid solution, preparation method of oxide solid solution, lithium ion battery anode material and preparation method of lithium ion battery anode material

ActiveCN102627332AThe composition is determined and reliableImprove stabilityCell electrodesManganese oxides/hydroxidesOXALIC ACID DIHYDRATENickel salt

The invention relates to oxide solid solution, a preparation method of the oxide solid solution, a lithium ion battery anode material and a preparation method of the lithium ion battery anode material. The oxide anode material is prepared by using the oxide solid solution as precursors. The preparation method of the oxide anode material comprises the steps of adding mixed water solution of nickel salt, cobalt salt and manganese salt into oxalic acid or oxalate water solution to produce nickel, cobalt and manganese oxalate co-precipitated products, separating solid from liquid, washing, drying, calcining in an atmosphere of air and decomposing to obtain the oxide solid solution; and mixing and grinding the solid solution and lithium salt, drying and roasting at high temperature to obtain the oxide anode material. The solid solution is an ideal raw material for preparing the oxide anode material, the process stability and the product consistency are improved and the material performance is improved; and the oxide anode material is a high-voltage and high-capacity anode material. The preparation methods are suitable for the large-scale, economic, stable and reliable production of the solid solution and the oxide anode material.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

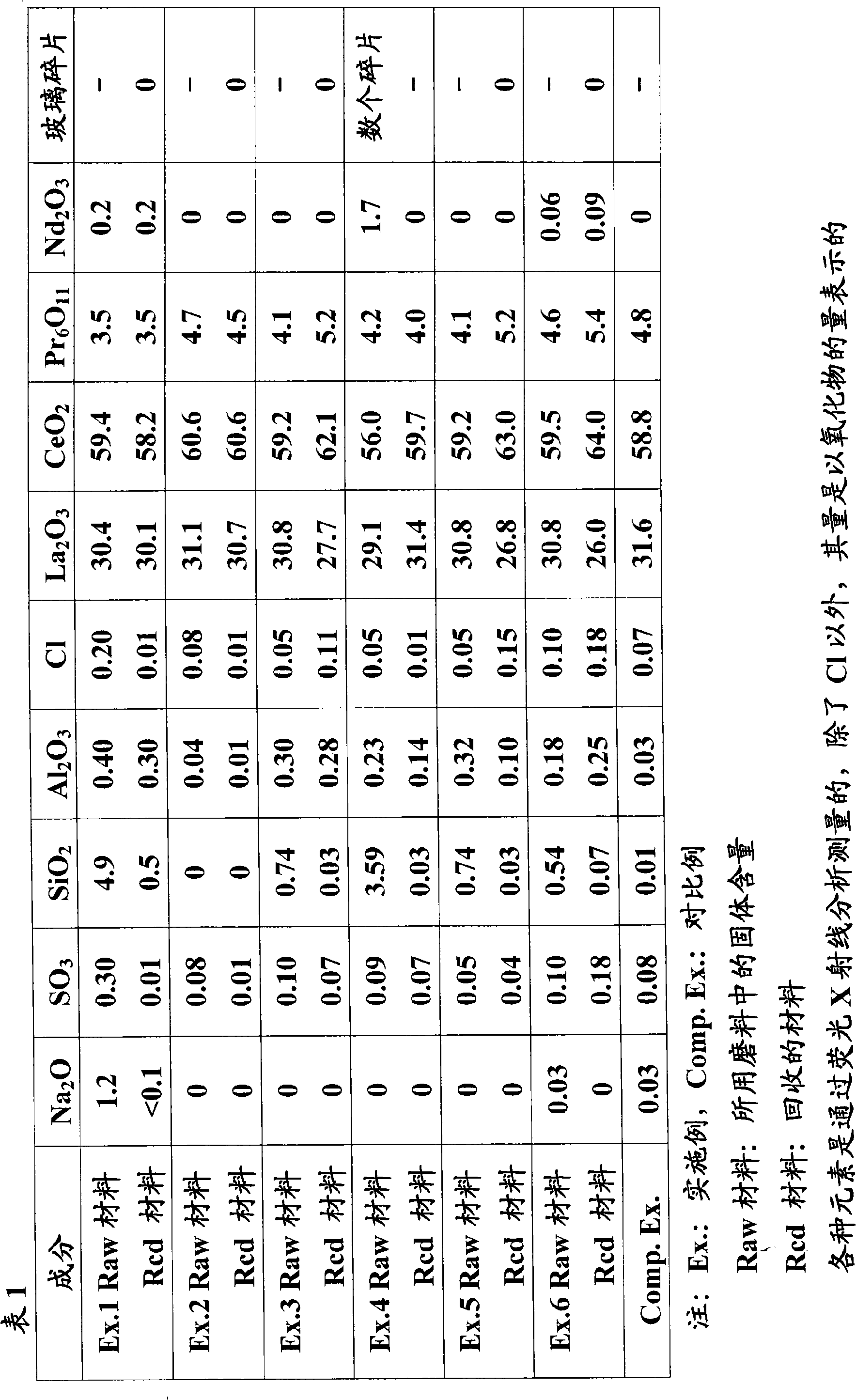

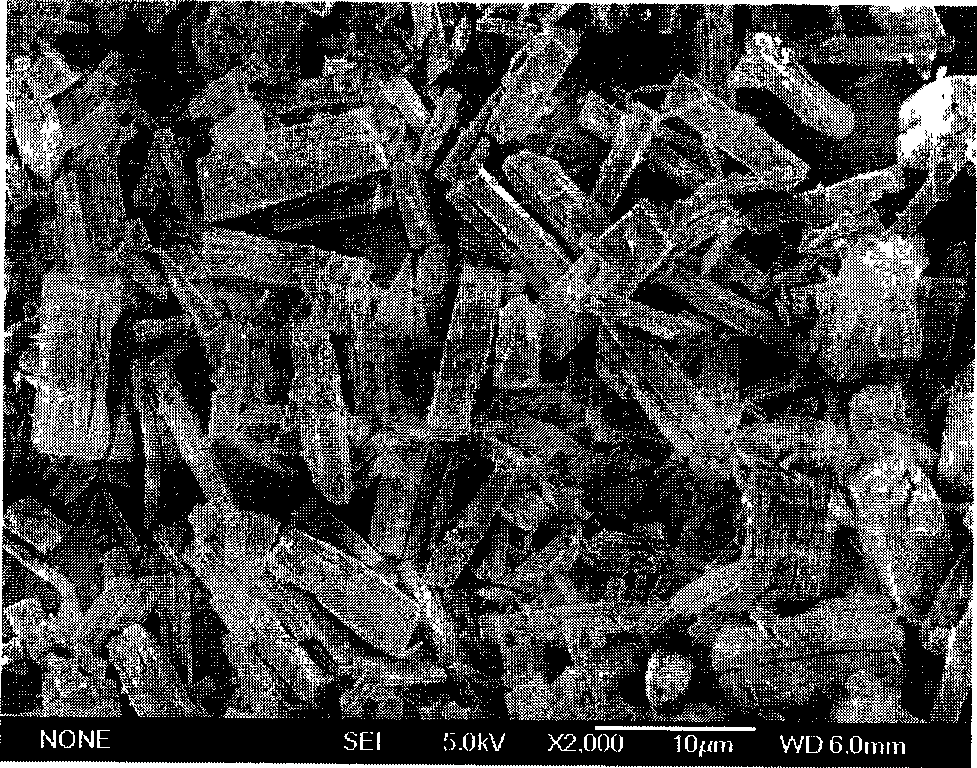

Process for recovering rare earth oxide from waste liquid containing rare earth element, and process for producing rare earth oxide using same

InactiveCN1675131AImprove efficiencySolid waste disposalRare earth metal compoundsDicarbonateOxalate

ABSTRACT Rare earth oxides capable of being re-used as an abrasive are recovered from an abrasive waste liquid by a process comprising the steps of (1) mixing and heating a rare earth element-containing waste liquid with an acid, to dissolve rare earth elements contained in the liquid; (2) removing insoluble matter from the rare earth element solution; (3) incorporating a soluble carbonate salt or a soluble hydrogencarbonate salt, or an oxalic acid in the rare earth element solution, to convert the rare earth elements to rare earth carbonates or rare earth oxalates; (4) separating the rare earth carbonates or rare earth oxalates from a slurry of the rare earth carbonates or rare earth oxalates; (5) baking the separated rare earth carbonate or rare earth oxalate to produce rare earth oxides; and (6) recovering the rare earth oxides.

Owner:SHOWA DENKO KK

Cerium oxide-zirconium oxide based composite rare-earth oxide with high specific surface area and high oxygen storage capacity and preparation method thereof

ActiveCN103191711ATotal pore volumeFresh specific surface area is highDispersed particle separationCatalyst activation/preparationZirconium hydrideSlurry

The invention discloses a method for preparing a cerium oxide-zirconium oxide based composite rare-earth oxide. The method comprises the following steps of: (1) heating a zirconium salt solution at room temperature, slowly adding sulfate ions, controlling the temperature rise rate so that the temperature is increased in the range of 90-95 DEG C when the sulfate ions are added completely, and then preserving heat for 20-100 minutes, thereby forming a zirconium basic sulfate composite salt precursor; (2) adding a cerium salt and a rare-earth metal salt to the precursor solution and stirring evenly, thereby obtaining a slurry; (3) settling the slurry by using basic carbonate and / or a basic oxalate solution, thereby obtaining a precipitate; and (4) filtering and washing the precipitate obtained in the step (3), removing purities, and calcining the washed precipitate. The cerium oxide-zirconium oxide based composite rare-earth oxide prepared by the method by controlling raw materials and process conditions has the characteristics of being high in total fine pore volume, high in fresh specific surface area, high in oxygen storage capacity and the like.

Owner:CHAOZHOU THREE CIRCLE GRP

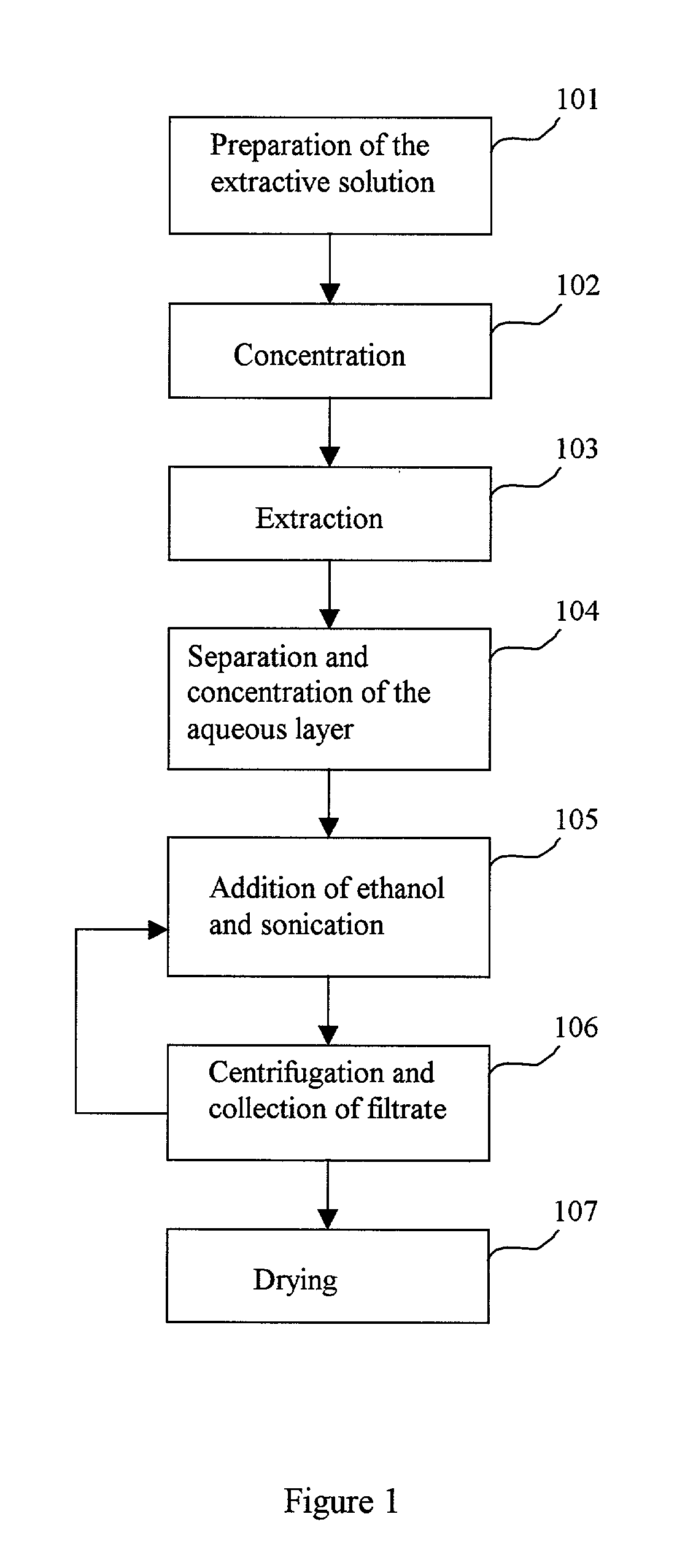

Process for extracting glycoside using an aqueous two-phase system

An aqueous two-phase system for extracting glycosides from a herb includes the extractive solution, about 5 wt %-30 wt % of salt, about 5 wt %-30 wt % of polyol and about 0.5 wt %-30 wt % of alcohols. The salt can be dihydrogen phosphate, hydrogen phosphate and phosphate or a mixture thereof, and it also can be sulfates, chlorides, oxalates, or acetates. In addition, a process for extracting glycosides using an aqueous two-phase system is disclosed. The procedures includes preparation of extractive solution, concentration and drying, phase separation, concentration of the water layer and drying, washing with solvent, sonication, centrifugation, concentration of filtrate and drying of the final products.

Owner:IND TECH RES INST

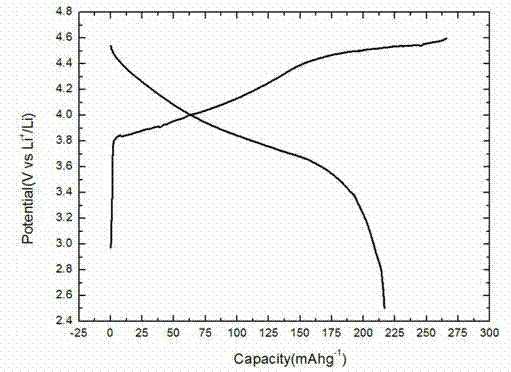

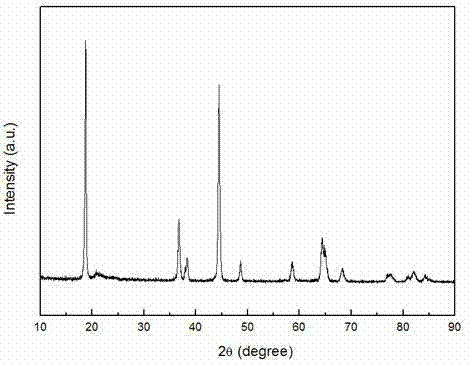

Oxalate coprecipitation preparation method for high-capacity lithium-rich cathode material

InactiveCN102730761AImprove structural stabilityImprove charge and discharge specific capacityCell electrodesManganese oxides/hydroxidesOXALIC ACID DIHYDRATEPhysical chemistry

The invention relates to an oxalate coprecipitation preparation method for a high-capacity lithium-rich cathode material. The preparation method is characterized by comprising the following concrete steps: dissolving soluble Ni salt, or Co salt and Mn salt, or Ni salt, Co salt and Mn salt in a proper amount of deionized water according to a stoichiometric ratio to prepare a metal salt solution with certain concentration, dissolving oxalate or oxalic acid in deionized water to prepare an oxalate solution with certain concentration, mixing the metal salt solution with an oxalate or oxalic acid solution in a way of straight adding, reverse adding or combined adding, adjusting the pH value of a mixed solution to be in a range of from 6.5 to 8.5, allowing a coprecipitation solution to be formed, and carrying out filtration with filter paper, rinsing with deionized water and drying on the coprecipitation solution so as to obtain precipitation precursor; and subjecting excess Li salt and the precipitation precursor in a certain stoichiometric ratio to ball milling and mixing and carrying out high temperature sintering so as to obtain an xLi2MnO3.(1 - x)LiMO2 (wherein M is Co, Ni1 / 2Mn1 / 2 or Ni1 / 3Co1 / 3Mn1 / 3) material at last. The method costs little and does not need a high temperature in preparation of a lithium-rich material and allows the shape and the size of the prepared material to be easily controllable.

Owner:CHINA FIRST AUTOMOBILE

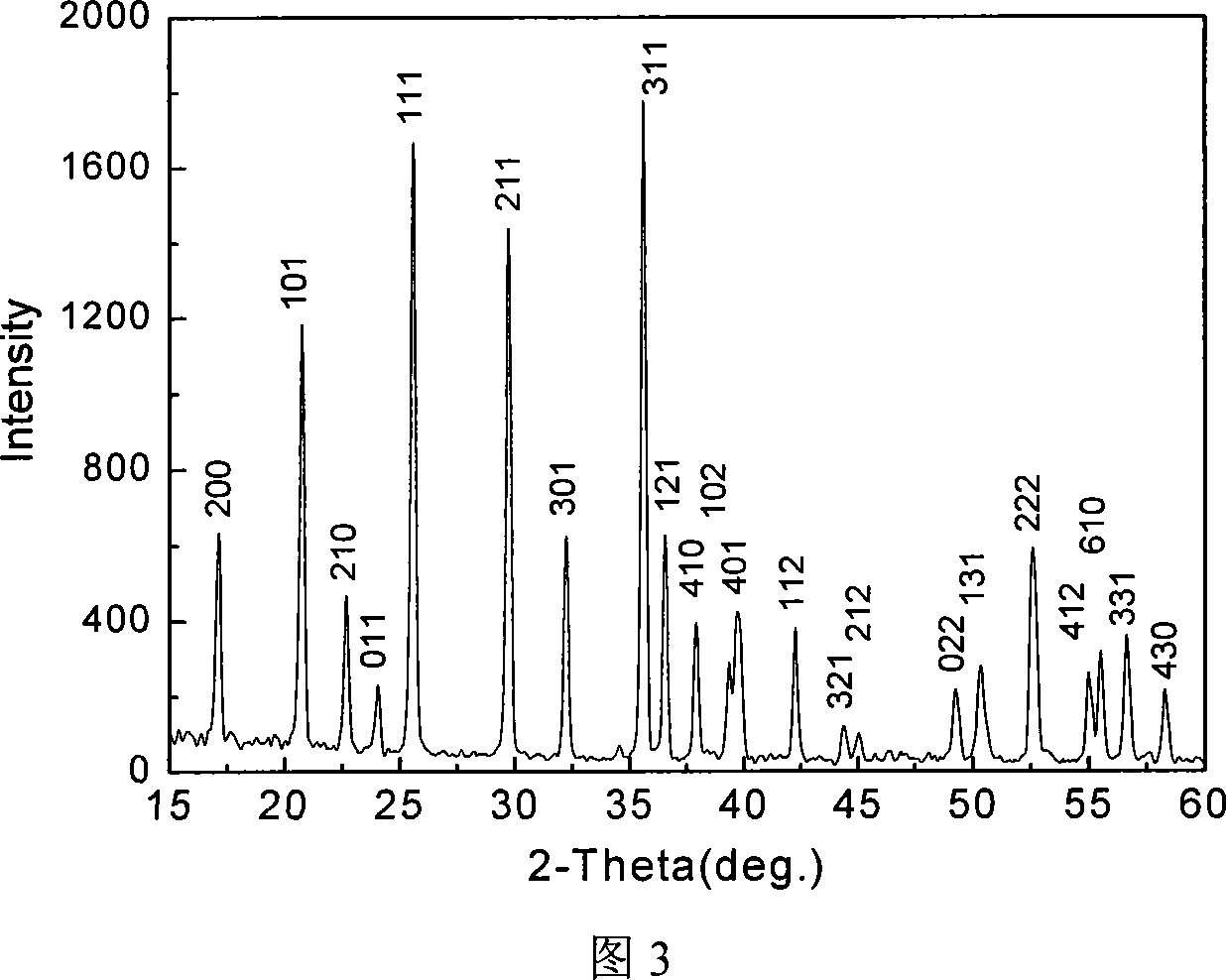

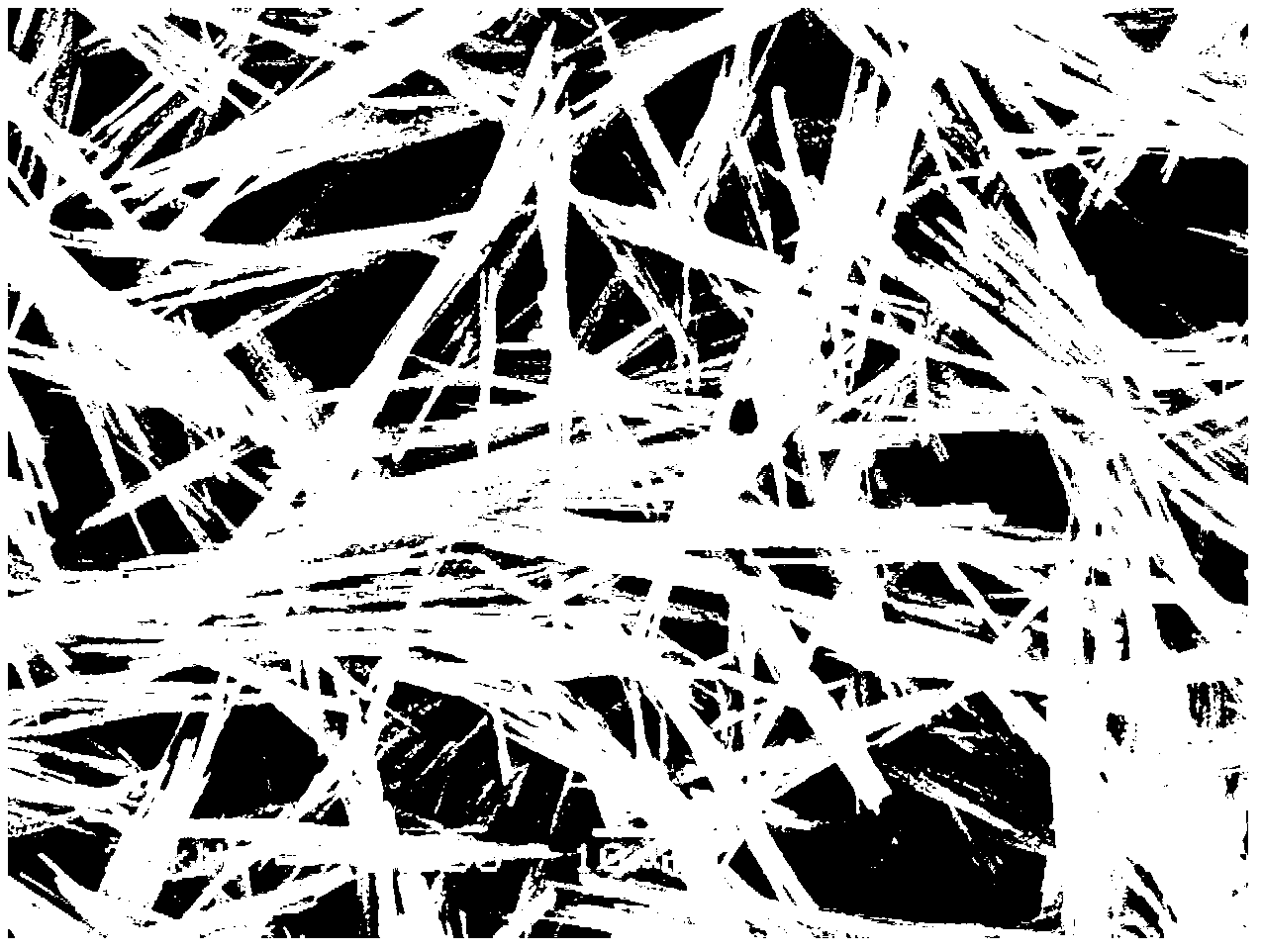

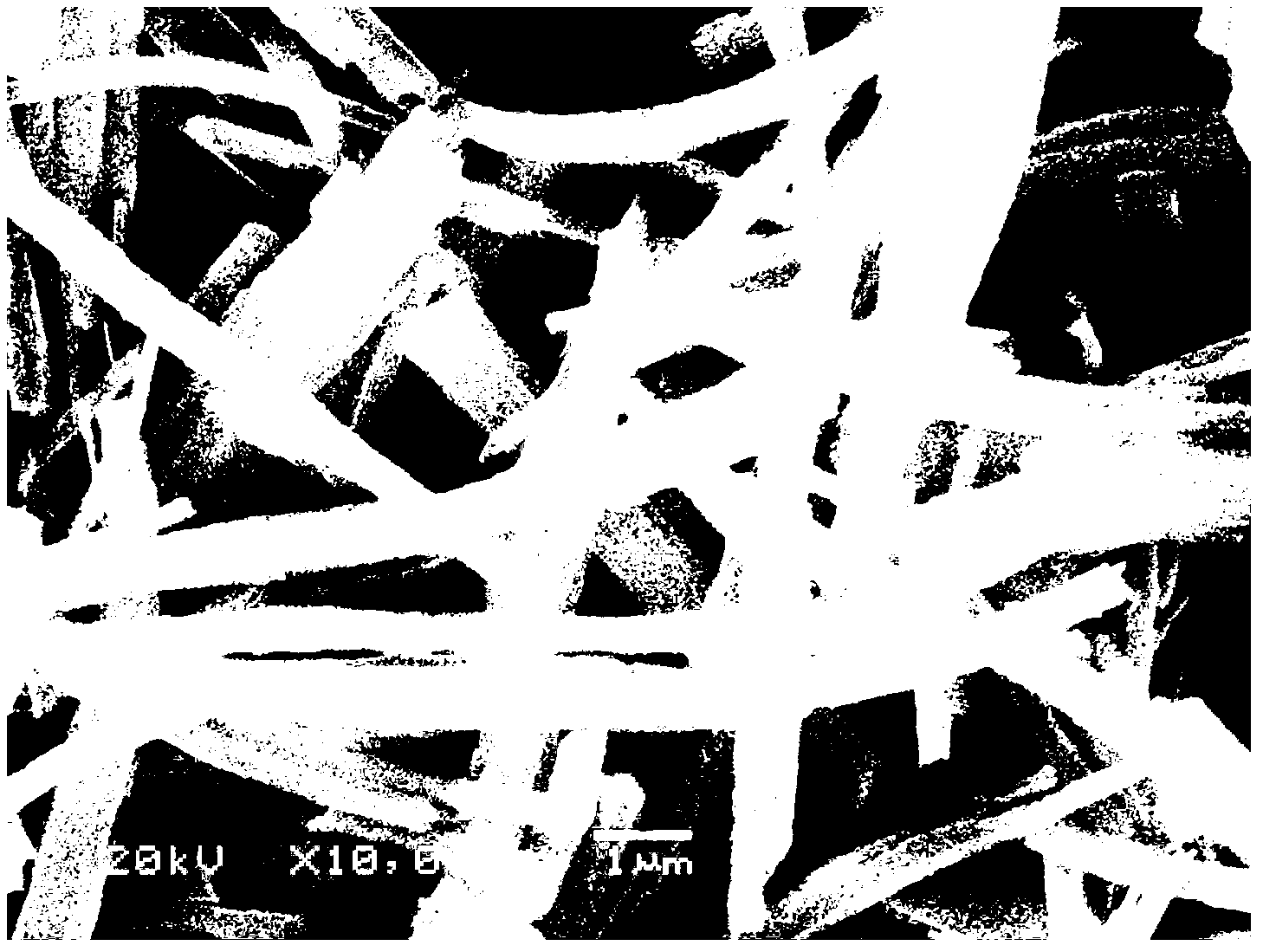

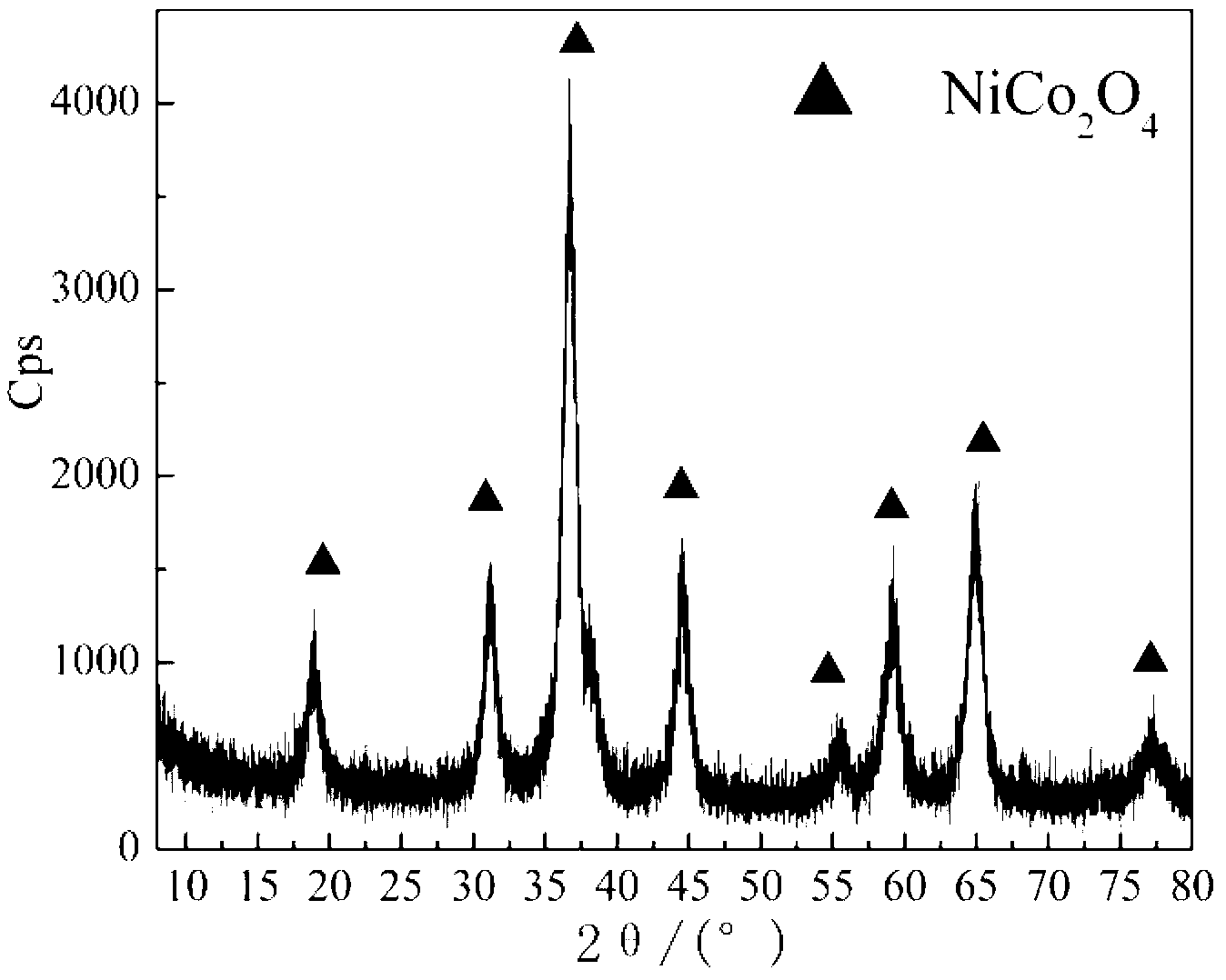

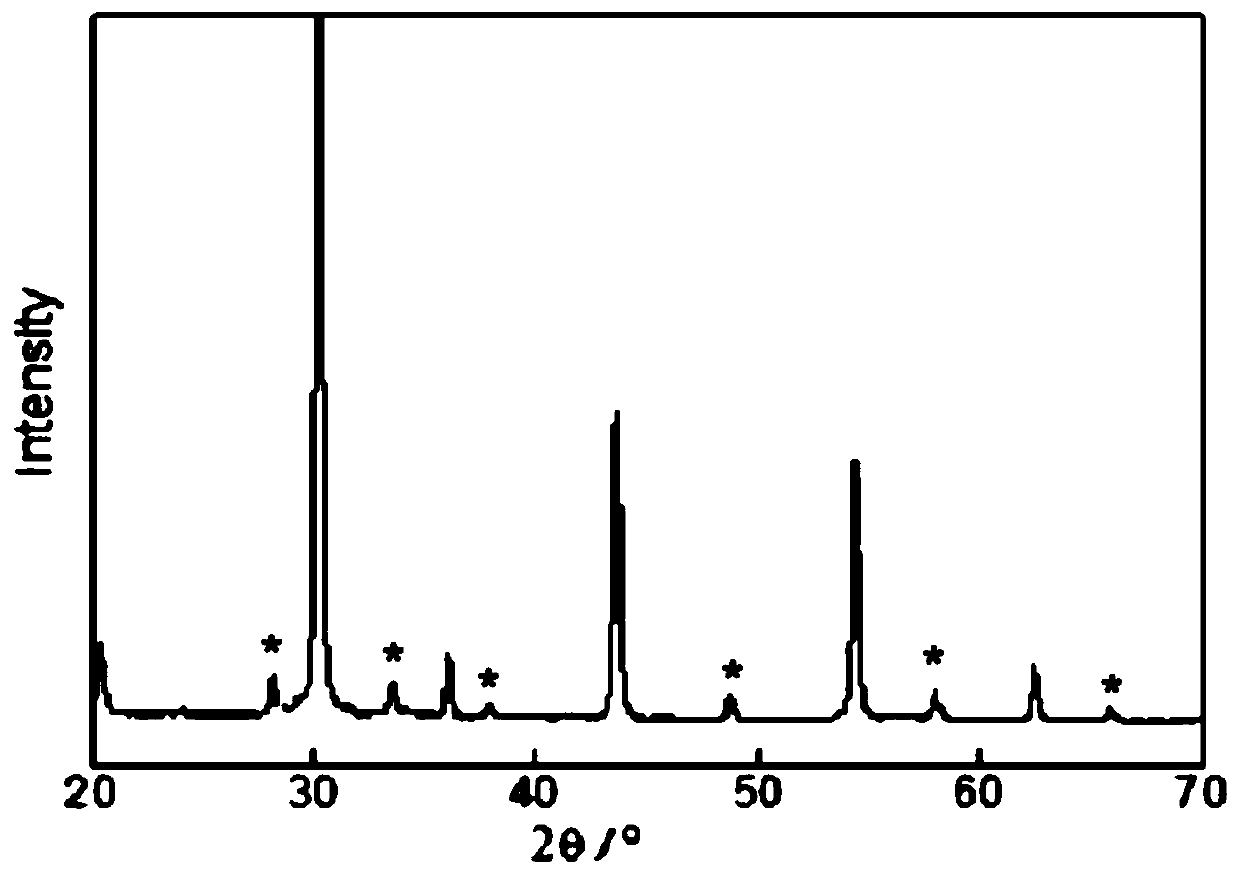

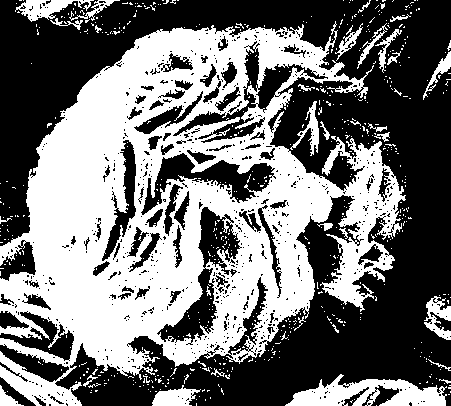

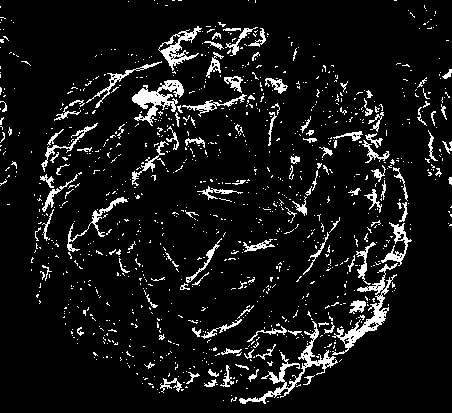

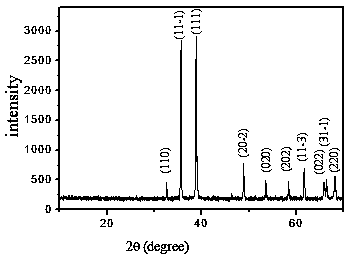

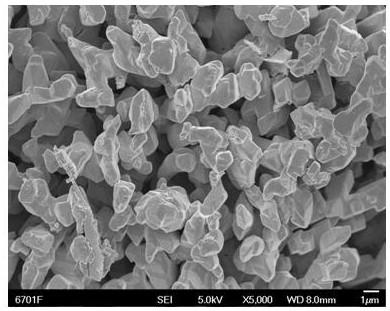

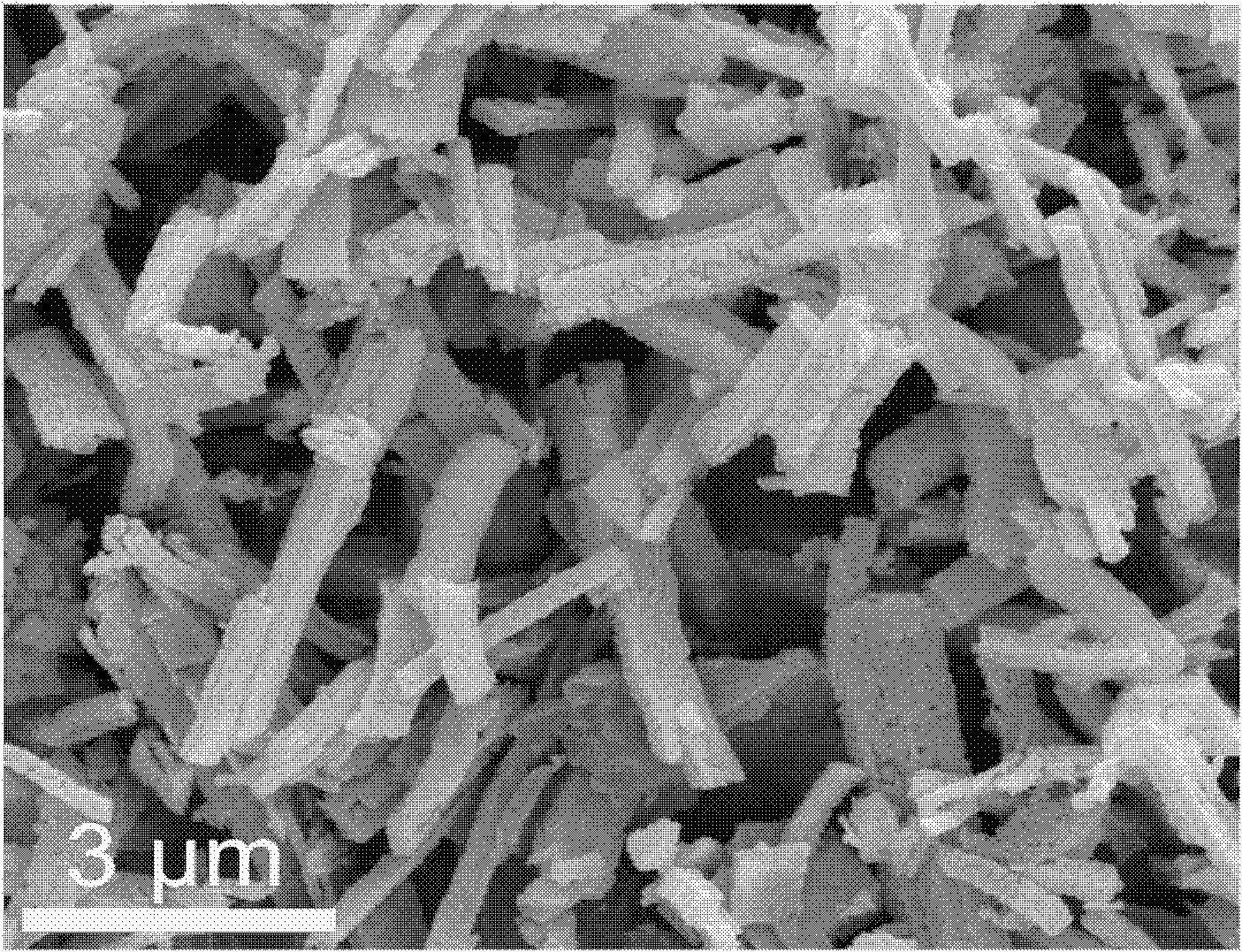

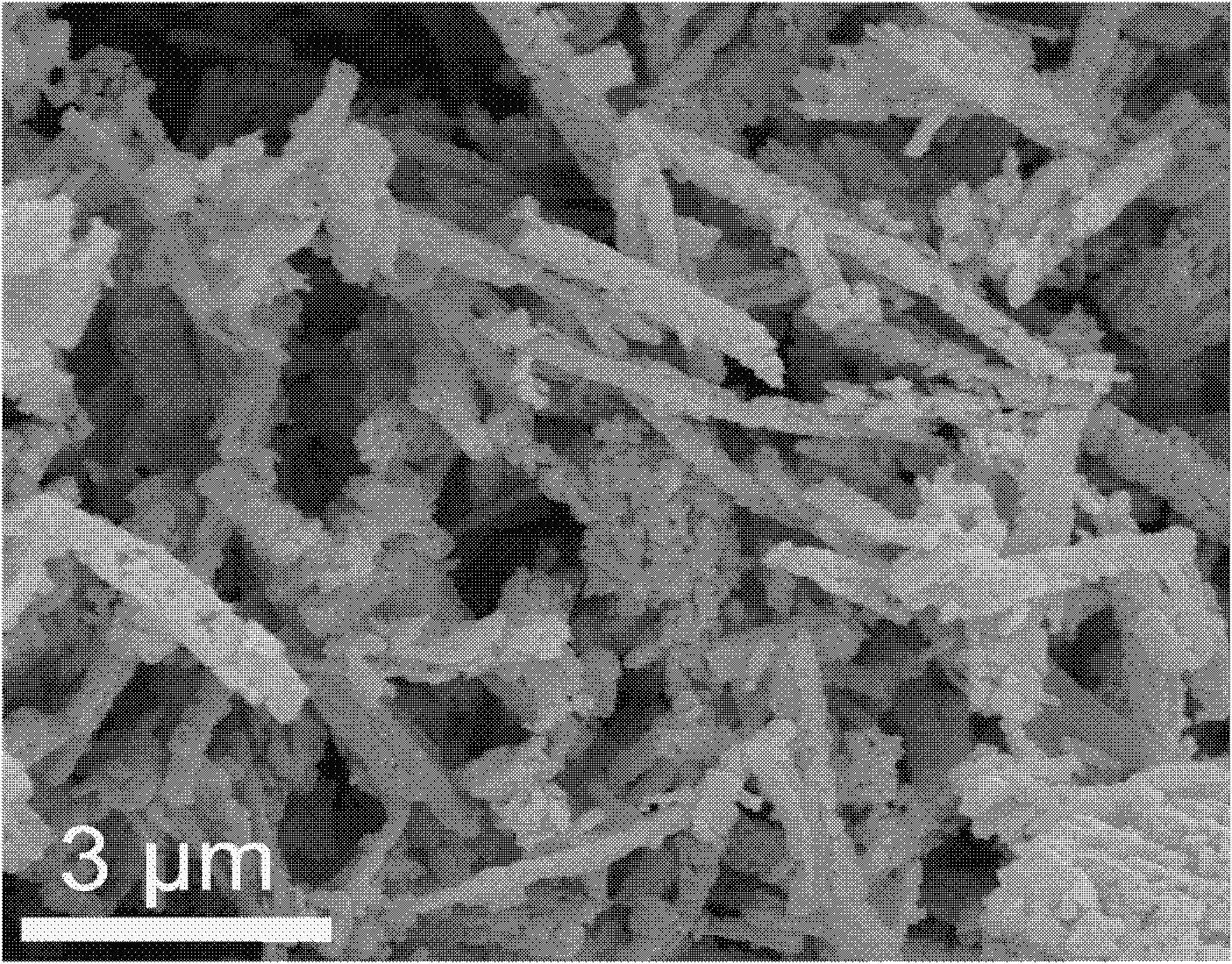

Preparation method of mesoporous nickel cobaltate fiber and application thereof

ActiveCN103318978AEasy to operateGood experimental reproducibilityCell electrodesNickel compoundsFiberAir atmosphere

The invention brings forward a preparation method of mesoporous nickel cobaltate fiber. According to the preparation method, an organic solvent is added during the preparation process of a precursor; a mixed phase of a water phase and an organic phase is used as a solvent, soluble nickel salt and cobalt salt are used as raw materials, and oxalate is used as a precipitating agent; in a system of Ni<2+>-Co<2+>-NH3-NH4<+>-SG<n->-C2O4<2->-H20-C2H5OH, a fibrous precursor is prepared; and the fibrous precursor is subjected to thermal decomposition in the air atmosphere at 250-400 DEG C so as to obtain the mesoporous NiCo2O4 fiber. According to the invention, coprecipitation based on the Ni-Co ratio set in the raw materials is effectively realized. The prepared NiCo2O4 powder is a cubic phase, has high purity and large specific surface area, is fibrous and porous, and is applicable to be used as a catalyst or an alkaline solution oxygen-evolution / hydrogen-evolution electrode material or direct alcohol fuel cell anode catalyst. The method provided by the invention is simple to operate and easy to control, has advantages of mild condition and low cost, and is suitable for commercialized production.

Owner:CENT SOUTH UNIV

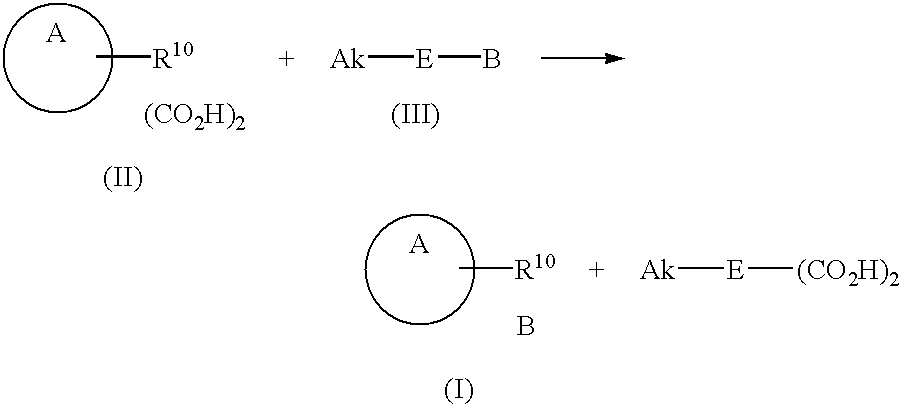

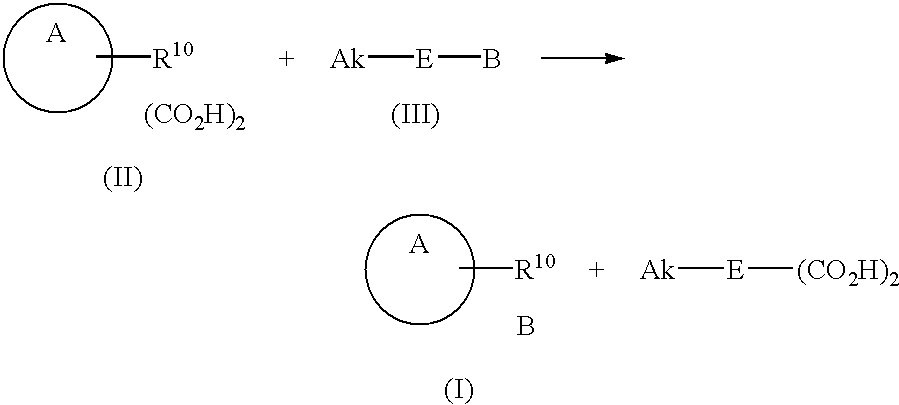

Process for the preparation of basic antibiotic inorganic acid addition salts and oxalate intermediate

A production process which comprises subjecting a basic antibiotic.oxalate (II) to salt-exchange with an alkali earth metal salt (III) of an inorganic acid:wherein the ring A means the basic antibiotic; R<10 >means a protected functional group used in organic synthesis; Ak-E means the alkali earth metal; and B means the inorganic acid, respectively.

Owner:EISIA R&D MANAGEMENT CO LTD

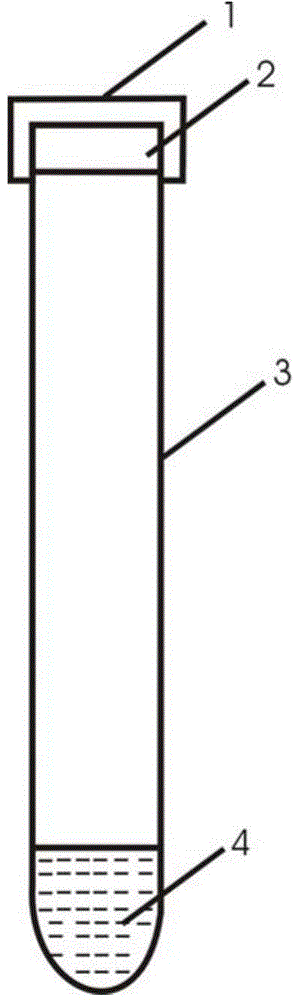

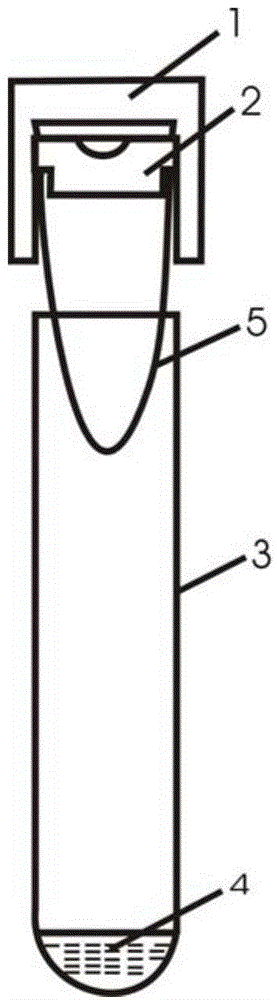

Blood sample collecting device

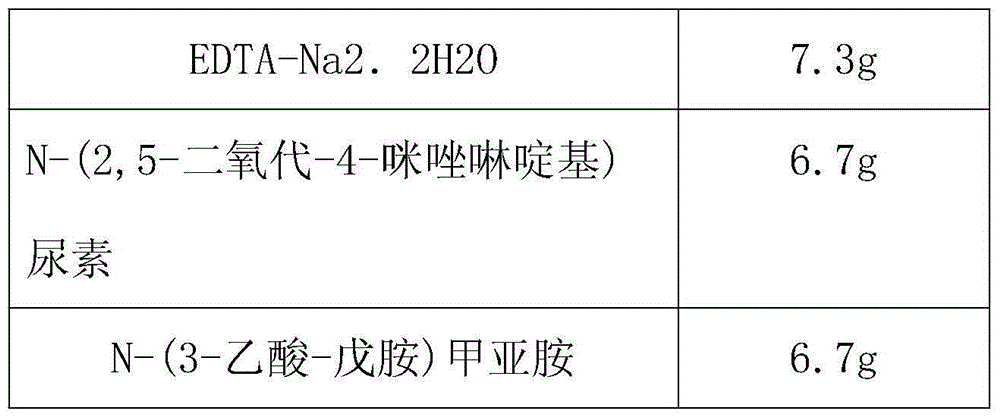

ActiveCN104673623AImprove integrityFor long-term storageBioreactor/fermenter combinationsBiological substance pretreatmentsBlood plasmaSodium hydroxide

The invention discloses a blood sample collecting device. The collecting device comprises a collecting tube, wherein an orifice of the collecting tube is provided with a sealing rubber plug, the outside of the rubber plug is provided with a protective cap, the collecting tube is filled with additives, the additives are composed of a blood anticoagulation, a hemocyte nucleic acid stabilizing agent, a blood plasma nucleic acid stabilizing agent, and a pH buffer solution; the blood anticoagulation is one or more of oxalate, heparinate and citrate, the pH buffer solution is one of glycine-sodium hydroxide-hydrochloric acid buffer solution; the hemocyte nucleic acid stabilizing agent is one or more of allantoin, 5,5-dimethyl hydantoin and oxazolidine; the blood plasma nucleic acid stabilizing agent is N-acetic acid azomethine, N-(3-acetic acid-amylamine)azomethine. The blood sample collecting device simultaneously contains the hemocyte nucleic acid stabilizing agent and the blood plasma nucleic acid stabilizing agent, and does not contain free aldehyde material, so that the blood sample can be stored in long term at normal temperature, and the free nucleic acid level of the blood sample can be stabilized, and the completeness of the free nucleic acid can be maintained.

Owner:广州维帝医疗技术有限公司

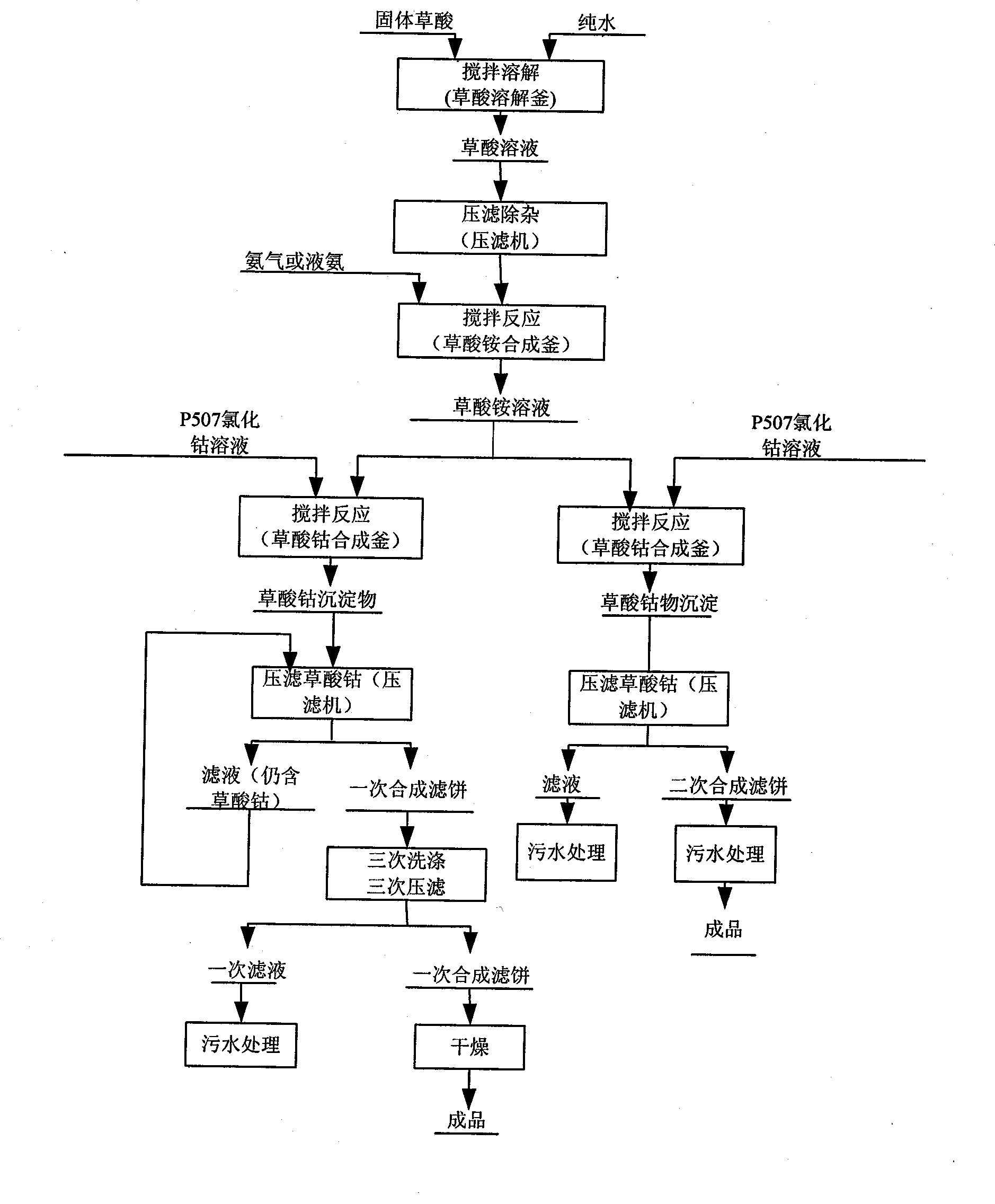

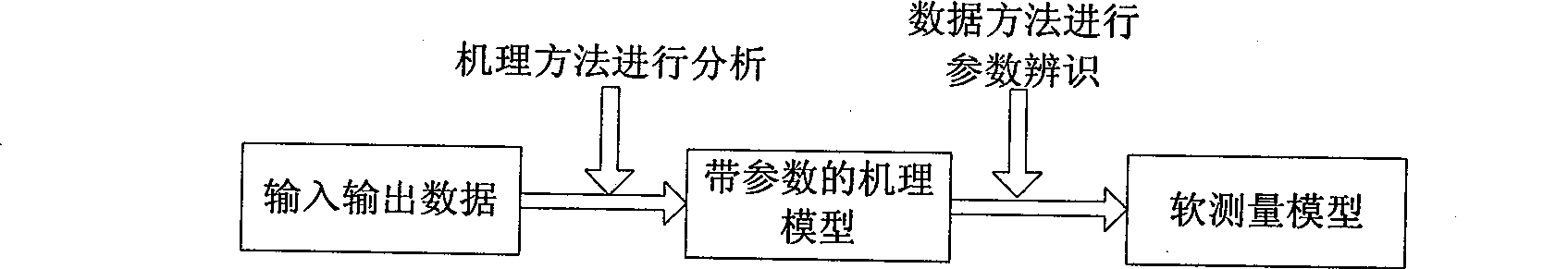

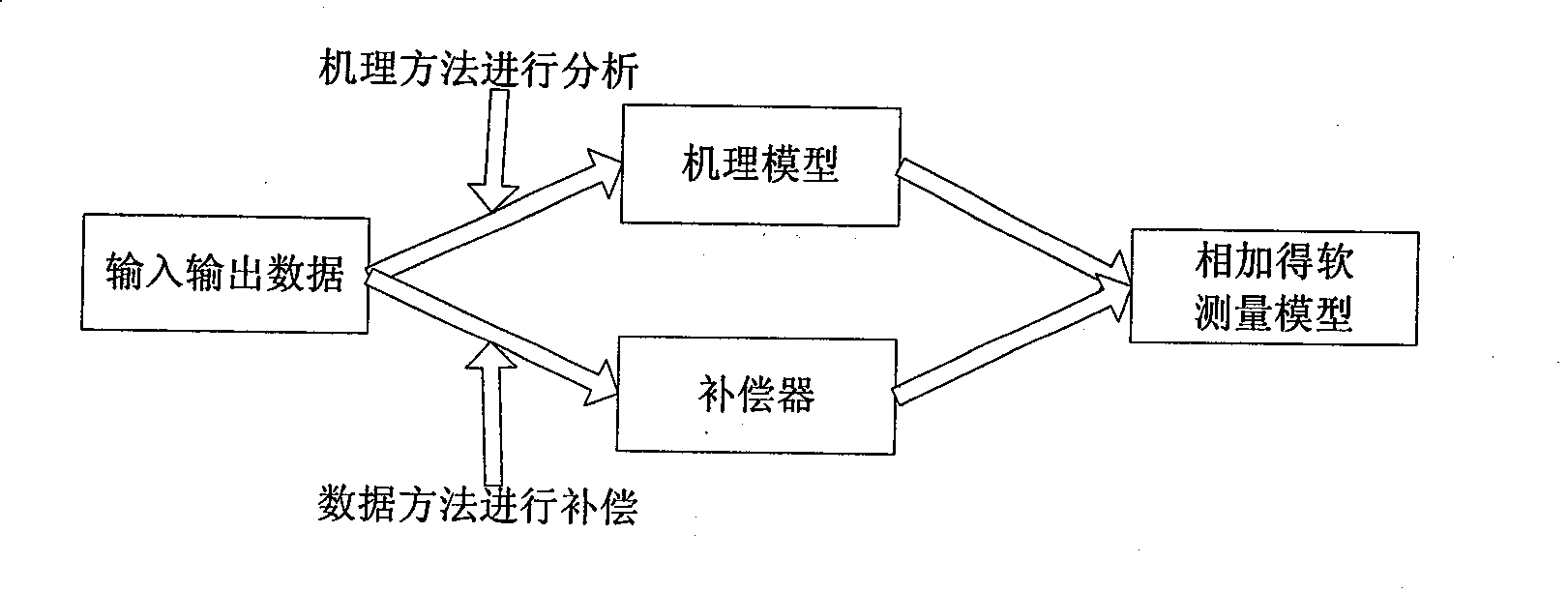

Cobalt oxalate coarseness prediction technique in hydrometallurgy synthesis course

InactiveCN101482750AComplex process monitoringImplement inputOrganic chemistryTotal factory controlSoftware systemPredictive methods

The present invention provides a cobalt oxalate granularity real-time prediction method in hydrometallurgy synthesis process. The method comprises the steps of data collecting, auxiliary variable selecting, standardized processing, hybrid model establishing, etc. The invention is characterized in that a parallel-connected structure hybrid model composed based on mechanism model and based on data driving model is established. A genetic algorithm is adopted for confirming the related model parameter in the mechanism model. A model based on data driving is used as an error compensating model of mechanism model. The invention also provides a software system which actualizes the cobalt oxalate granularity prediction. The software system comprises a main program, a database and a human-machine interaction interface. The system software uses a microcomputer of hydrometallurgy synthesis process control system as a hardware platform. When the cobalt oxalate granularity real-time prediction method is used for the cobalt oxalate synthesis process of a certain hydrometallurgy factory for predicting the granularity of cobalt oxalate, the prediction result is in the preset error range. The cobalt oxalate granularity real-time prediction method according to the invention has the advantages of simple model, strong interpretability, good extrapolation property and higher prediction precision.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Process for recovering rare earth oxide, process for producing abrasive containing rare earth oxide and polishing method using abrasive

InactiveCN101353178AImprove efficiencyOther chemical processesRare earth metal compoundsOXALIC ACID DIHYDRATERare-earth element

The present invention relates to process for recovering rare earth oxide from waste liquid containing rare earth elements, and process for producing rare earth oxides by the recovering process. Rare earth oxides capable of being re-used as an abrasive are recovered from an abrasive waste liquid by a process comprising the steps of (1) mixing and heating a rare earth element-containing waste liquid with an acid, to dissolve rare earth elements contained in the liquid; (2) removing insoluble matter from the rare earth element solution; (3) incorporating a soluble carbonate salt or a soluble hydrogencarbonate salt, or an oxalic acid in the rare earth element solution, to convert the rare earth elements to rare earth carbonates or rare earth oxalates; (4) separating the rare earth carbonates or rare earth oxalates from a slurry of the rare earth carbonates or rare earth oxalates; (5) baking the separated rare earth carbonate or rare earth oxalate to produce rare earth oxides; and (6) recovering the rare earth oxides.

Owner:SHOWA DENKO KK

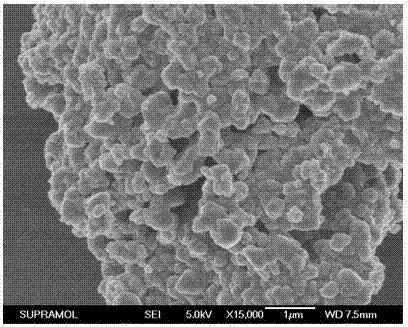

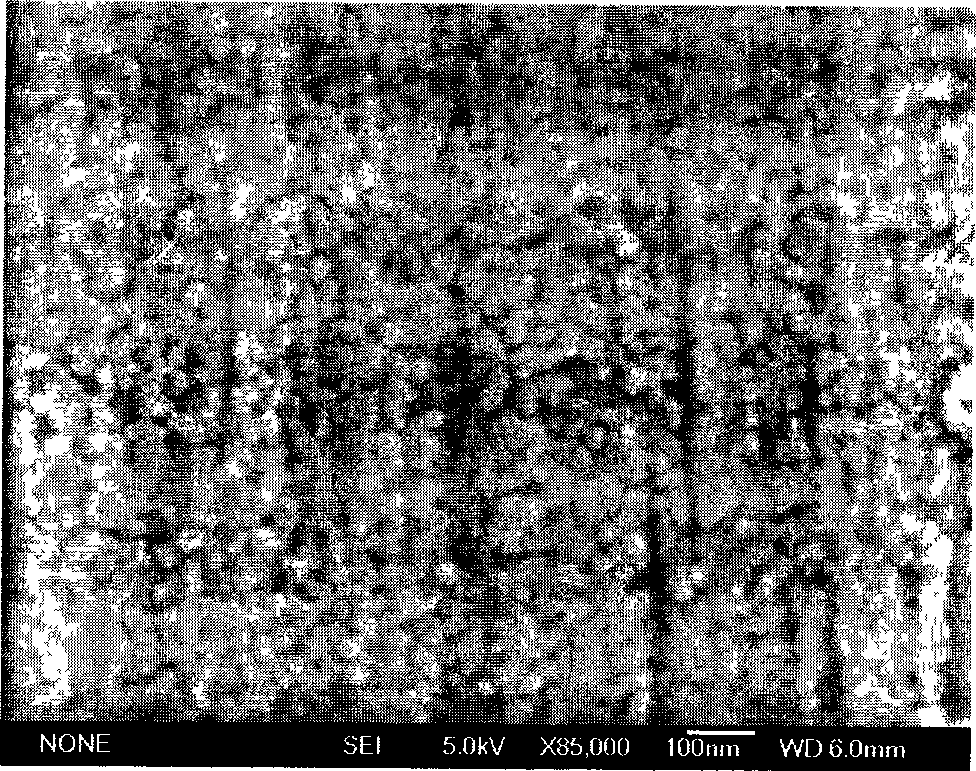

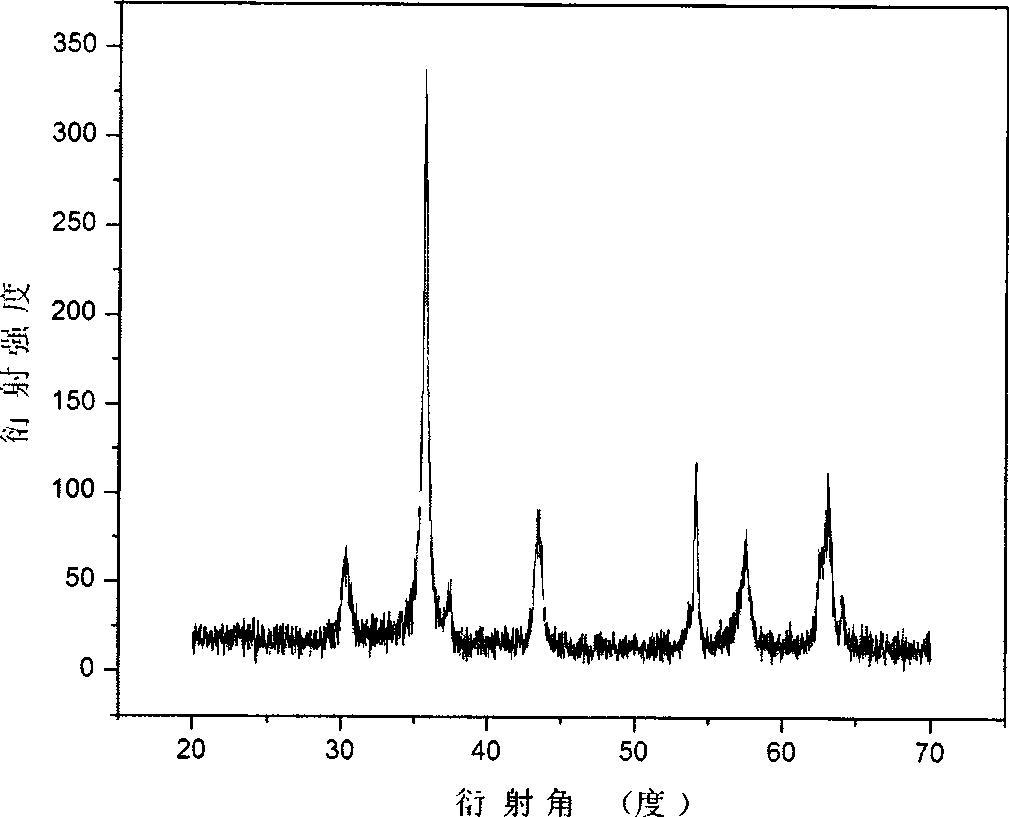

Nano-superstructure polyporous material of ferrite and method of preparing the same

The invention relates to a ferrite nanometer superstructure porous material and a method for preparing the same, in particular to a method for preparing a nickel ferrite, cobalt ferrite or zinc ferrite nanometer superstructure porous material. The preparation method comprises that: sodium oxalate is used as a precipitator, the soluble nickel, cobalt or zinc salt used as a raw material reacts with the soluble iron salt to prepare a precursor of oxalate, and the precursor is degraded by calcination at certain temperature to obtain the nickel ferrite, cobalt ferrite or zinc ferrite nanometer superstructure porous material. The nickel ferrite, cobalt ferrite or zinc ferrite nanometer superstructure porous material synthesized by the method has the advantages of high purity, uniform size, good dispersibility, mild reaction conditions, simple equipment, easily controlled process conditions and low cost, and meets the need of the actual production.

Owner:HUAZHONG NORMAL UNIV

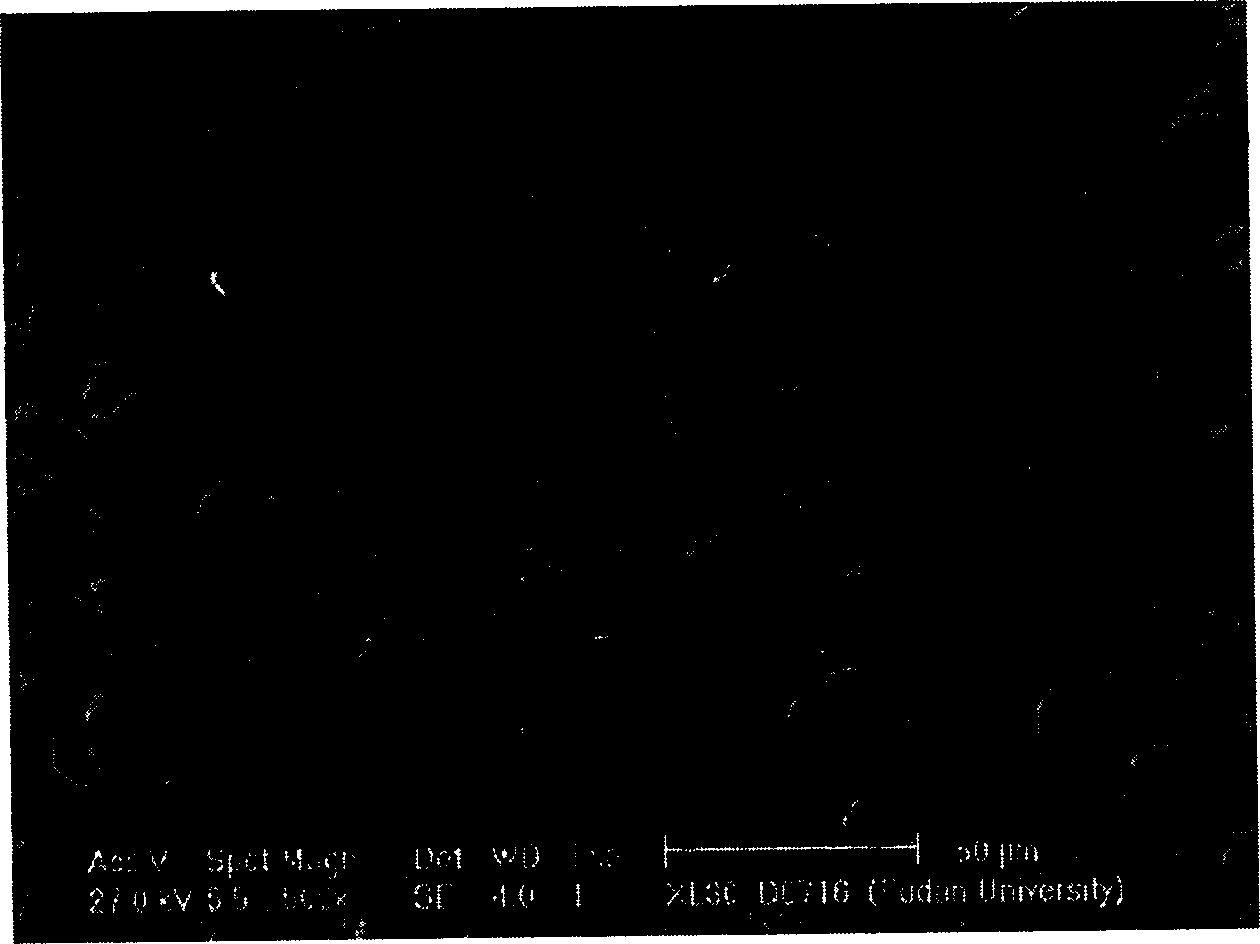

Composite oxide catalyst for preparing propylene by oxidative dehydrogenation of propane and preparation method thereof

InactiveCN1557546AEasy to manufactureLow priceHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsComposite oxideChemical technology

The present invention belongs to the field of chemical technology, and is one kind of composite nano RE oxide catalyst with low temperature activity for propane oxidizing dehydrogenation process to prepare propylene and its preparation process. The catalyst consists of cerium oxide and transition metal oxide, and has cerium content of 10-90 mol%. The catalyst is prepared through oxalate co-precipitation process including dissolving certain amount of oxalic acid in water or alcohol solution, dripping in solution of soluble salt of cerium and transition metal, ageing in stirring, centrifugal separation, drying, roasting and other steps. The prepared catalyst has unique nano solid solution structure and rather high catalytic activity at low temperature of 300 deg.c, and is used for propane oxidizing dehydrogenation process to prepare propylene to result in propylene yield as high as 15 %.

Owner:FUDAN UNIV

Method for preparing perovskite-type composite oxide high entropy ceramic powder by ion compensation mixture coprecipitation

The invention discloses a method for preparing perovskite type composite oxide high entropy ceramic powder by ion compensation mixture coprecipitation method, belonging to the field of lead-free dielectric ceramic materials. The method comprises the following steps: dissolving the chloride of Ba and Sr or the mixture of the two, and the chloride of Zr, Sn, Ti, Nb (Hf), Y or Ce, Er (Mn) and oxalate, and mixing to form a mixed salt solution, wherein the concentration of easily lost components Ba, Sn, Ti and Hf is compensated; taking aqueous ammonia solution as precipitant or mixed aqueous solution of sodium carbonate and ammonia water as precipitant; reacting the mixed salt solution and the precipitant solution under intense stirring to form a precipitate; using ammonia bicarbonate solutionas buffer solution, repeatedly cleaning and filtering the precipitate; obtaining high entropy ceramic powder after vacuum azeotropic distillation and roasting.

Owner:CHANGZHOU UNIV

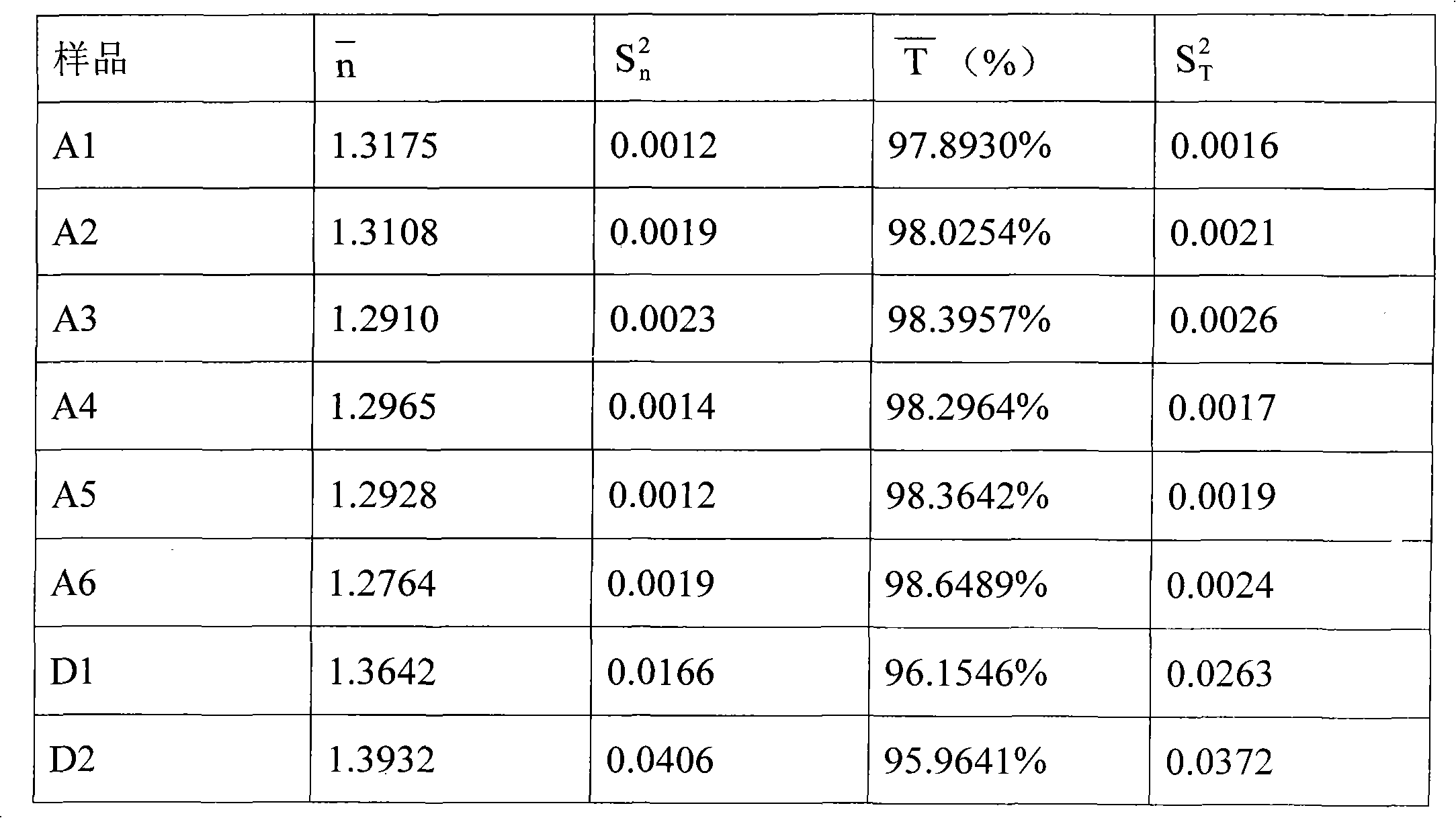

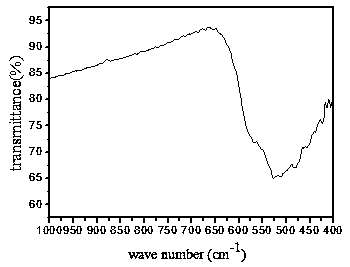

Method for preparing silica antireflective film

InactiveCN101995589ALow refractive indexThe control method is simple and convenientCoatingsOptical elementsDicarbonateCITRATE ESTER

The invention provides a method for preparing a silica antireflective film, which comprises the following steps of: a) uniformly mixing a tetraethoxysilane and absolute ethyl alcohol-containing system, and preparing silica sol under the alkaline condition through a sol-gel method, wherein the system also comprises one or more of soluble carbonate, bicarbonate, citrate, tartrate and oxalate; and b) coating the silica sol prepared in the step a) and performing heat treatment so as to prepare the silica antireflective film. By the provided preparation method, an antireflective film with the refractive index of 1.18 to 1.32 and the light transmittance of 97 to 99 percent can be stably prepared, the technology is simple and controllable, and the repeatability is high.

Owner:BYD CO LTD

Porous lithium iron phosphate/carbon composite microspheres and preparation method thereof

InactiveCN103078114ALarge specific surface areaHigh tap densityCell electrodesPhosphorus compoundsCarbon compositesIron salts

The invention provides porous lithium iron phosphate / carbon composite microspheres and a preparation method thereof. The porous lithium iron phosphate / carbon composite microspheres and the preparation method thereof are characterized in that iron phosphate oxalate is used as a precursor and the preparation method comprises the following steps: (1) dispersing solution of iron salt and phosphate solution into a precipitating agent ethanol, adding lithium salt, carrying out ultrasonic stirring to enable the solution of iron salt, the phosphate solution and the lithium salt to be totally dissolved, and adding a certain quantity of oxalic ethanol solution into the obtained solution; (2) placing the obtained mixture into an oven to dry at a certain temperature so as to obtain a yellow jelly iron phosphate oxalate precursor; and (3) after mixing a carbon source and the iron phosphate oxalate precursor, calcining to obtain the porous lithium iron phosphate / carbon composite microspheres. The preparation method provided by the invention is low in cost and is simple and easy to operate; the pH does not need to be regulated; the products have high purity, high tap density and good repeatability; the products are spherical particles formed by self-assembling disk nano-scale particles, and thus, the specific surface area is large; and moreover, the diffusion path of lithium ions is greatly shortened, so that the porous lithium iron phosphate / carbon composite microspheres have excellent electrochemical property and are suitable for large-scale production.

Owner:QINGDAO UNIV OF SCI & TECH

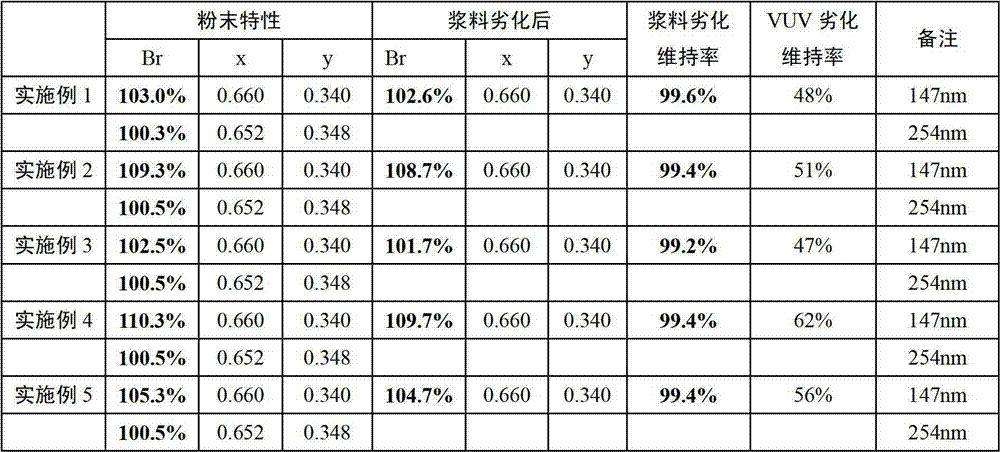

Preparation method for yttrium gadolinium europium oxide red fluorescent powder applicable to 3D PDP

InactiveCN102766457AReduce hydrolysisImprove surface integritySolid cathode detailsLuminescent compositionsRare earthYttrium

A preparation method for yttrium gadolinium europium oxide red fluorescent powder applicable to a 3D PDP (Plasma Display Panel) comprises the steps as follows: a rare earth oxalate coprecipitation body is prepared by adopting a coprecipitation method, rare earth metal oxide is balanced and dissolved in nitric acid or chlorhydric acid to form a rare earth metal salt solution; an oxalic acid solution or a carbonate solution is prepared and added into the rare earth metal salt solution to obtain rare earth metal oxalate or a carbonate precipitate; the carbonate precipitate is filtered and isolated, dried and burned to obtain a rare earth oxide coprecipitation body; the coprecipitation body is oxidized and burned to form a yttrium gadolinium europium oxide red fluorescent powder burned body; the rare earth oxide coprecipitation body is added with a cosolvent and is loaded in an aluminum oxide crucible and is burned under high temperature in an oxidizing furnace; after burned, the rare earth oxide coprecipitation body is shattered after burning to obtain a yttrium gadolinium europium finished product; and finally, the yttrium gadolinium europium oxide red fluorescent powder is obtained according to a downstream treatment process. The fluorescent powder prepared according to the method has the advantages of high lighting brightness, good color purity, complete crystal morphology, small powder center particle size, simple manufacturing method and low production cost, and is suitable for industrial production.

Owner:CAIHONG GRP ELECTRONICS CO LTD

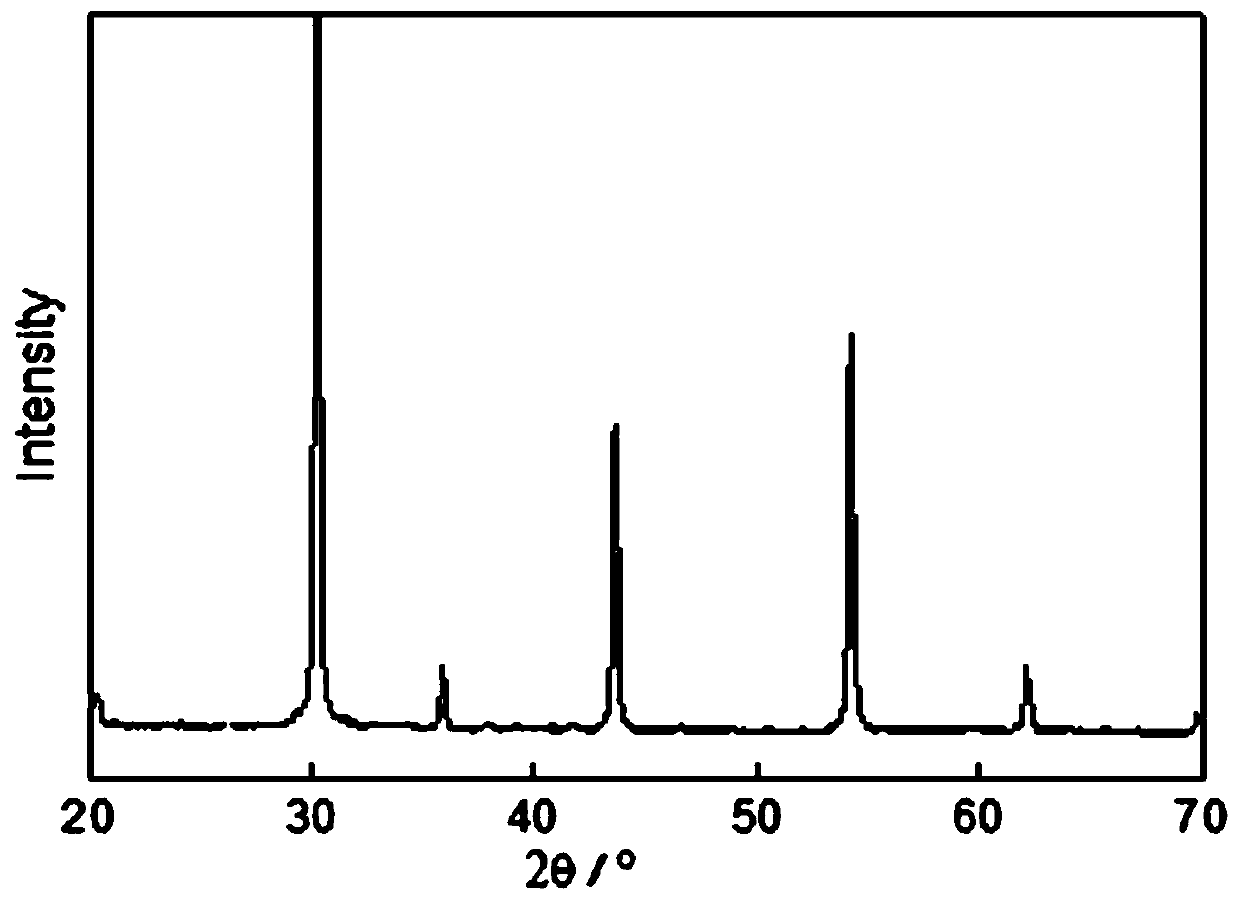

Preparation method of high-specific-surface CuMn2O4 catalyst for CO low-temperature oxidation removal

InactiveCN106031873ALarge specific surface areaSimple preparation processMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention discloses a preparation method of a high-specific-surface CuMn2O4 catalyst for CO low-temperature oxidation removal. The method comprises the steps that soluble copper salt and soluble manganese salt with the mole ratio being 1:2 are prepared into a solution with the total mole concentration of 0.21-0.45 mol / L, then, an ammonium oxalate solution with the mole concentration of 0.3-0.5 mol / L is added, the mixture continues to be stirred and is dried at the temperature of 60-90 DEG C after being precipitated and washed to obtain a copper manganese oxalate precursor, and the copper manganese oxalate precursor is heated at the heating speed of 0.5-2 DEG C / min to 300-400 DEG C to be roasted for 0.5-3 h to obtain the spinel type CuMn2O4 catalyst. The prepared CuMn2O4 catalyst has the advantages of being large in specific surface, simple in preparation process, convenient to operate, good in repeatability and the like, can achieve oxidization removal of CO in air within the wide temperature range, and has the quite good stability.

Owner:HENAN NORMAL UNIV

Preparation method and application of flaky nano copper oxide

ActiveCN110436508ASimple preparation processReduce manufacturing costNanotechnologyCopper oxides/halidesPhotocatalytic degradationCopper salt

The invention discloses a preparation method and application of flaky nano copper oxide. The preparation method of the flaky nano copper oxide mainly comprises the following steps: accurately weighingcopper salt and oxalic acid or oxalate, uniformly mixing the copper salt and the oxalic acid or the oxalate, then grinding, adding a proper amount of distilled water in the grinding process to enablethe mixture to be in a fluid state, heating, cleaning and drying after grinding to obtain a precursor copper oxalate, and calcining the precursor copper oxalate to obtain the flaky nano copper oxide.A preparation technology is simple, no organic solvent except ethanol is used in a preparation process, the preparation method is environment-friendly and safe, and prepared flaky nano copper oxide particles are uniform in size and small in particle size, and have good photocatalytic degradation performance on a methylene blue solution.

Owner:GANSU AGRI UNIV

Preparation method of nickel coated copper composite powder

The invention relates to a preparation method of nickel coated copper composite powder. The preparation method comprises the following process steps that copper salt and oxalate or carbonate take reaction to generate cupric oxalate or copper carbonate sediments, the filtering is carried out, pure water is used for flushing to be in a neutral state, and solution with the concentration being 10 to 80g / L is prepared; and nickel salt solution and the required oxalate or carbonate solution are prepared according to a proportion that the copper nickel weight ratio is 2:1 to 1:2 and are added into the cupric oxalate or copper carbonate solution for reaction to generate nickel coated copper resultants. The preparation method has the advantages that firstly, nickel salts are used for coating copper salts, then, the thermal decomposition is carried out, nickel coated copper powder is obtained, the production process is simple, the operation is easy, the production cost is low, and the industrial production can be realized. The nickel coated copper powder or alloy prepared by the method has the morphology in a spherical shape, a near-spherical shape, an irregular shape or a tree branch shape, and has the advantages that the powder dispersion is uniform, no segregation is generated, the coating effect is good, the coating is compact, the particle size is controllable, and the like. The nickel coated copper powder or alloy can be used for electromagnetic shielding materials and powder metallurgy prealloyed powder. The preparation method can be used for preparing nickel-copper alloy powder.

Owner:NAT ENG RES CENT FOR SPECIAL METAL MATERIALS OF TANTALUM & NIOBIUM

A kind of porous structure lithium manganate electrode material and preparation method and application

ActiveCN102280634AImprove electrochemical performanceIncrease contact areaCell electrodesManganateManganese

The invention provides a lithium manganese oxide electrode material with a porous structure. The material has a one-dimensional porous structure and comprises lithium manganese oxide porous nanorods, lithium manganese oxide porous submicron rods and lithium manganese oxide porous micron rods. A manufacturing method of the material comprises the following steps: adding oxalate into an organic mixed solution and then adding a manganese salt solution for reaction; carrying out centrifugation, separation and washing on a white product and then heating to decompose the processed white product to obtain a black product; and adding lithium to the black product for mixing and roasting to obtain a target product, namely, the lithium manganese oxide electrode material, wherein the lithium manganeseoxide electrode material can be used for manufacturing the lithium manganese oxide anode of a lithium ion battery. According to the invention, the lithium manganese oxide electrode material can form a spinel phase with rich lithium, has the larger specific area, and can increase the contact area of active substances and an electrolyte; the lithium manganese oxide electrode material has smaller internal grains which can form a dispersion channel capable of shortening ions, thus improving the electrochemical performance; and the lithium manganese oxide electrode material has good high multiplying power performance and cycle performance, thus being possible to apply to the new-generation power batteries massively. The manufacturing method is simple in process, easy to implement and beneficial to popularization and application.

Owner:NANKAI UNIV

Method for preparing fused salt-oxalate co-precipitation of lithium-rich materials for lithium batteries

InactiveCN102938458AContributes to structural stabilityImprove structural stabilityCell electrodesSalt solutionOxalate salt

The invention discloses a method for preparing fused salt-oxalate co-precipitation of lithium-rich materials for lithium batteries. The method is characterized in that a Ni, Co and Mn metal salt solution and an oxalate root solution are prepared, and the two solutions are mixed together in different dropwise adding mode to form precipitation to serve as a precursor. The precursor, fused salt and lithium salt are mixed and sintered, resultants are cleaned and dried to obtain high-volume lithium-rich cathode materials x Li2MnO3*(1-x) LiMO2 (M=Co, Ni1 / 2 Mn1 / 2, Ni1 / 3Co1 / 3Mn1 / 3). When the lithium-rich materials are prepared, liquid environments of the fused salt are helpful for contact and reaction of the materials, and accordingly, reaction start time is reduced and reaction time is shortened. The oxalate is used as a precipitator, resultant particles are uniform, any impurity is not introduced, and the stability of material structures is facilitated and the electrochemical performance is improved.

Owner:CHINA FIRST AUTOMOBILE

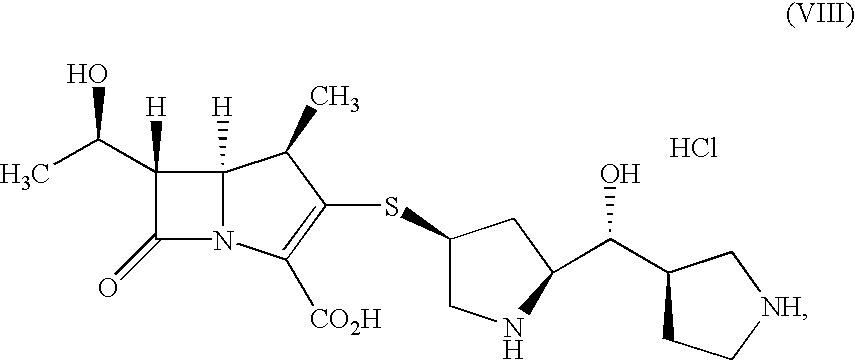

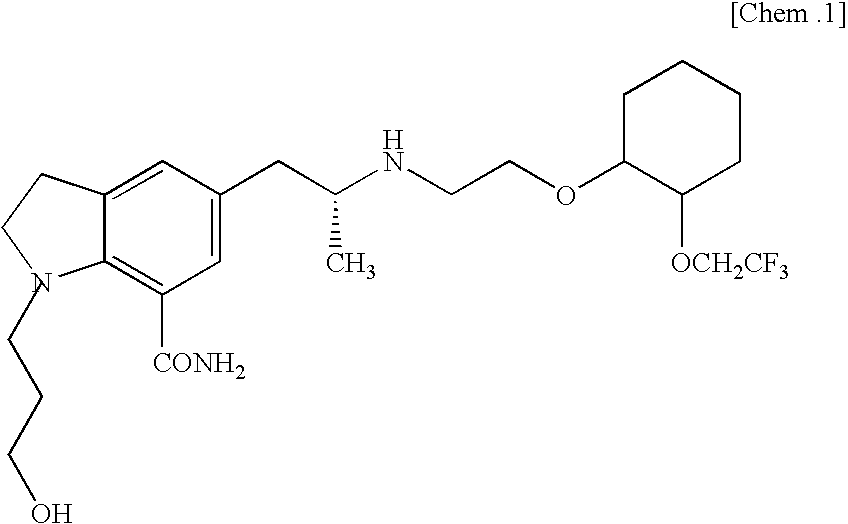

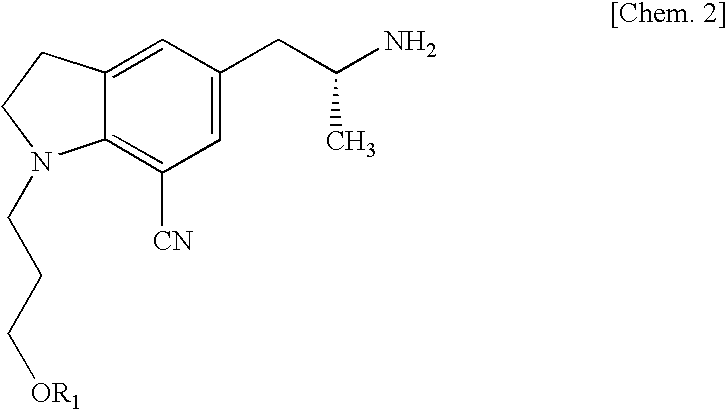

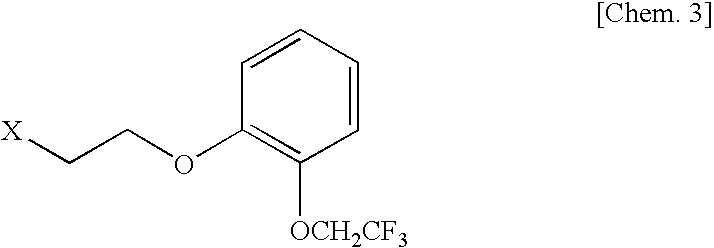

Indoline compound and process for producting the same

ActiveUS20070197627A1Simple methodEasy to handleBiocideOrganic active ingredientsPropyl benzoateOXALIC ACID DIHYDRATE

The present invention provides an industrial method production of silodosin, which is useful for a therapeutic agent for dysuria associated with benign prostatic hyperplasia. The production of silodosine is characterized by mixing 3-{7-cyano-5-[(2R)-2-({(2-[2-(2,2,2-trifluoroethoxy)-phenoxy]ethyl}amino]propyl]-2,3-dihydro-1H-indol-1-yl}-propyl benzoate and oxalic acid to yield the oxalate, subsequently hydrolyzing the oxalate salt to yield 1-(3-hydroxypropyl)-5-[(2R)-2-({2-[2-(2,2,2-trifluoroethoxy)phenoxy]ethyl}amino]propyl]-2,3-dihydro-1H-indole-7-carbonitrile and hydrolyzing the same, and manufacturing intermediates used therefore.

Owner:KISSEI PHARMA

Lubricant for cold forging and cold extruding and preparation method and using method thereof

InactiveCN107523386AStrong environmental protectionEasy to useLubricant compositionPolyethylene glycolTalc

The invention discloses a lubricant for cold forging and cold extruding and a preparation method and a using method thereof. The lubricant comprises distilled water, sodium carboxymethylcellulose, sodium polyacrylate, polymethacrylate, mica powder, talc powder, boron nitride, zinc stearate, sodium stearate, alkyl sodium sulfonate, diglycol, triethanolamine, polyvinylpyrrolidone, vinyl triethoxy silane, polyisobutene, polyethylene glycol, nonyl phenol polyoxyethylene ether, an ethylene-vinyl acetate copolymer, an alkaline silica sol, sodium silicate, a styrene-acrylic emulsion, oxalate, vulcanized fat, alkylated aromatic amine and sodium methylenedinaphthalene. The lubricant disclosed by the invention can adsorb a uniform plastic film formed on the surface of a workpiece, so that the workpiece and a mold are isolated by the lubricating film all the way, and the lubricant is good in environmental friendliness and convenient to use, can replace a phosphorizing-saponifying treatment process, and is a non-graphite high molecular lubricant suitable for cold forging and cold extruding forming of metals or nonferrous metals.

Owner:QINGDAO YUANDA GRAPHITE

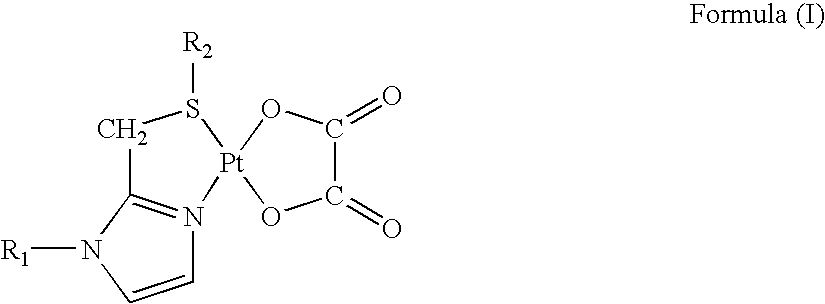

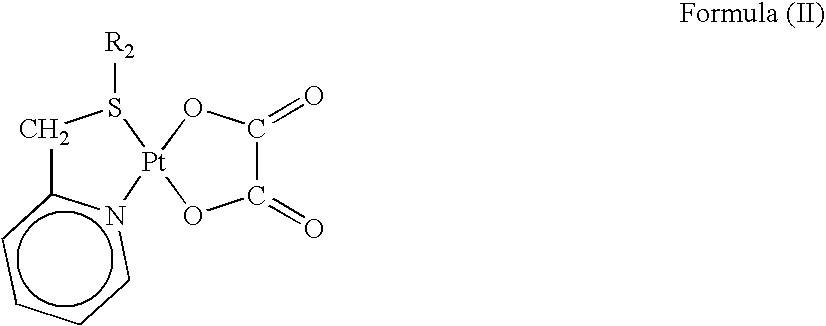

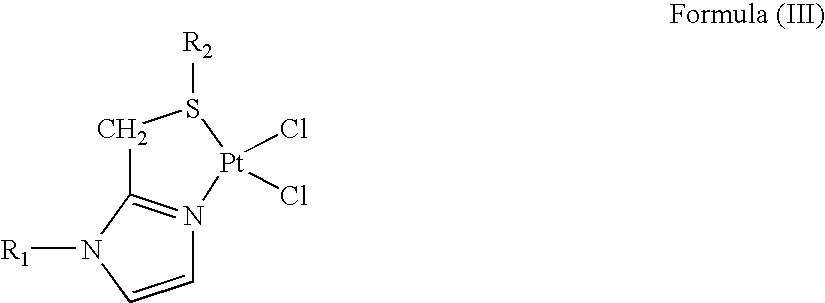

Preparation of Platinum(II) Complexes

This invention relates to a method for the preparation of a platinum(II) complex containing a neutral bidentate ligand, such as oxaliplatin. The method includes the step of reacting a halogenoplatinum complex containing a neutral bidentate ligand with an oxalate salt in a solvent, wherein more than 1 g / L of the oxalate salt is soluble in the solvent. The invention also relates to new platinum(II) complexes.

Owner:PLACTO TECH PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com