Preparation method of mesoporous nickel cobaltate fiber and application thereof

A technology of nickel cobalt oxide and fiber, applied in the field of preparation of nickel cobalt oxide, can solve the problems of low product purity, small specific surface area, low catalytic activity, etc., and achieve the effects of high purity, large specific surface area, and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

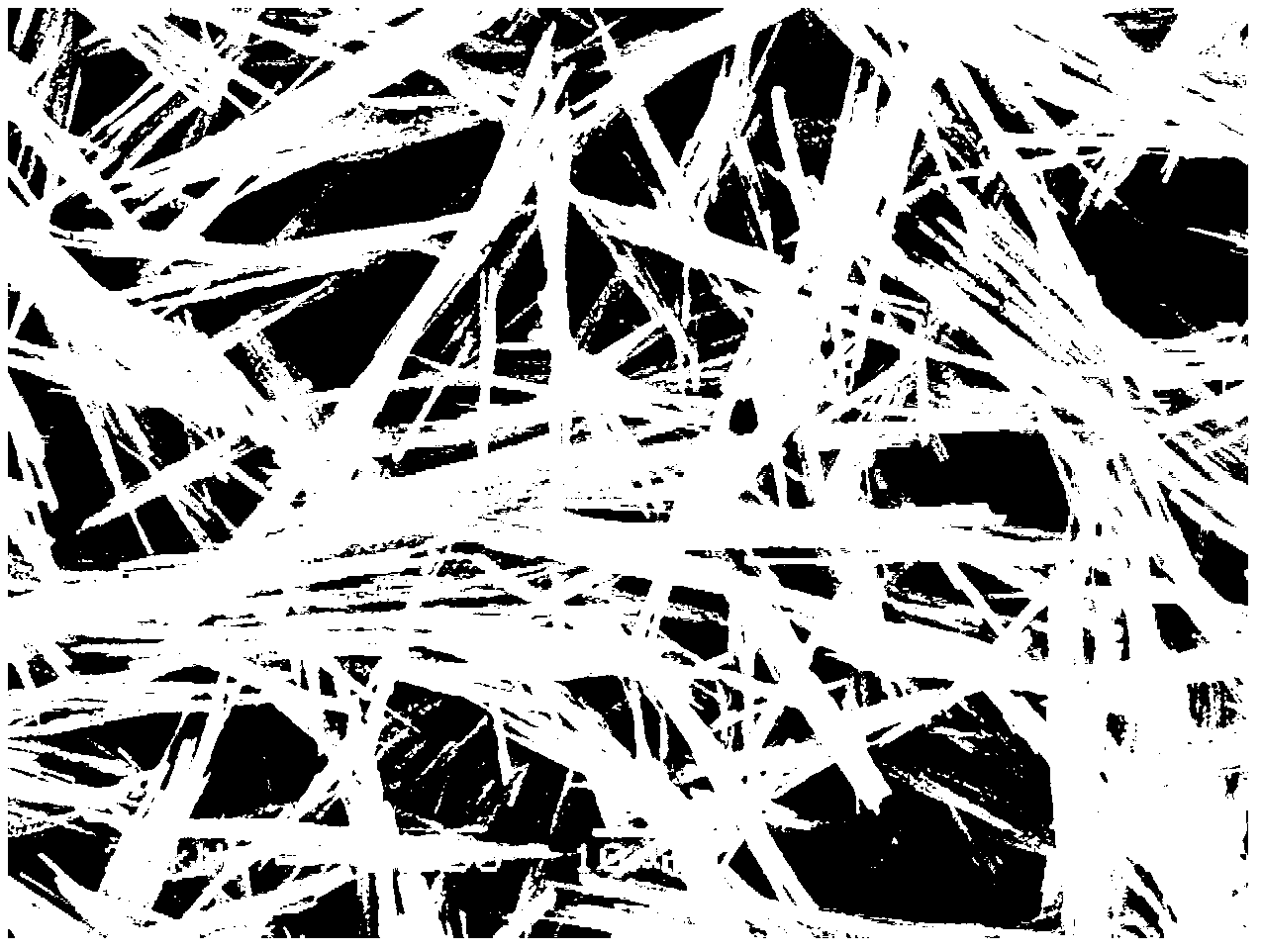

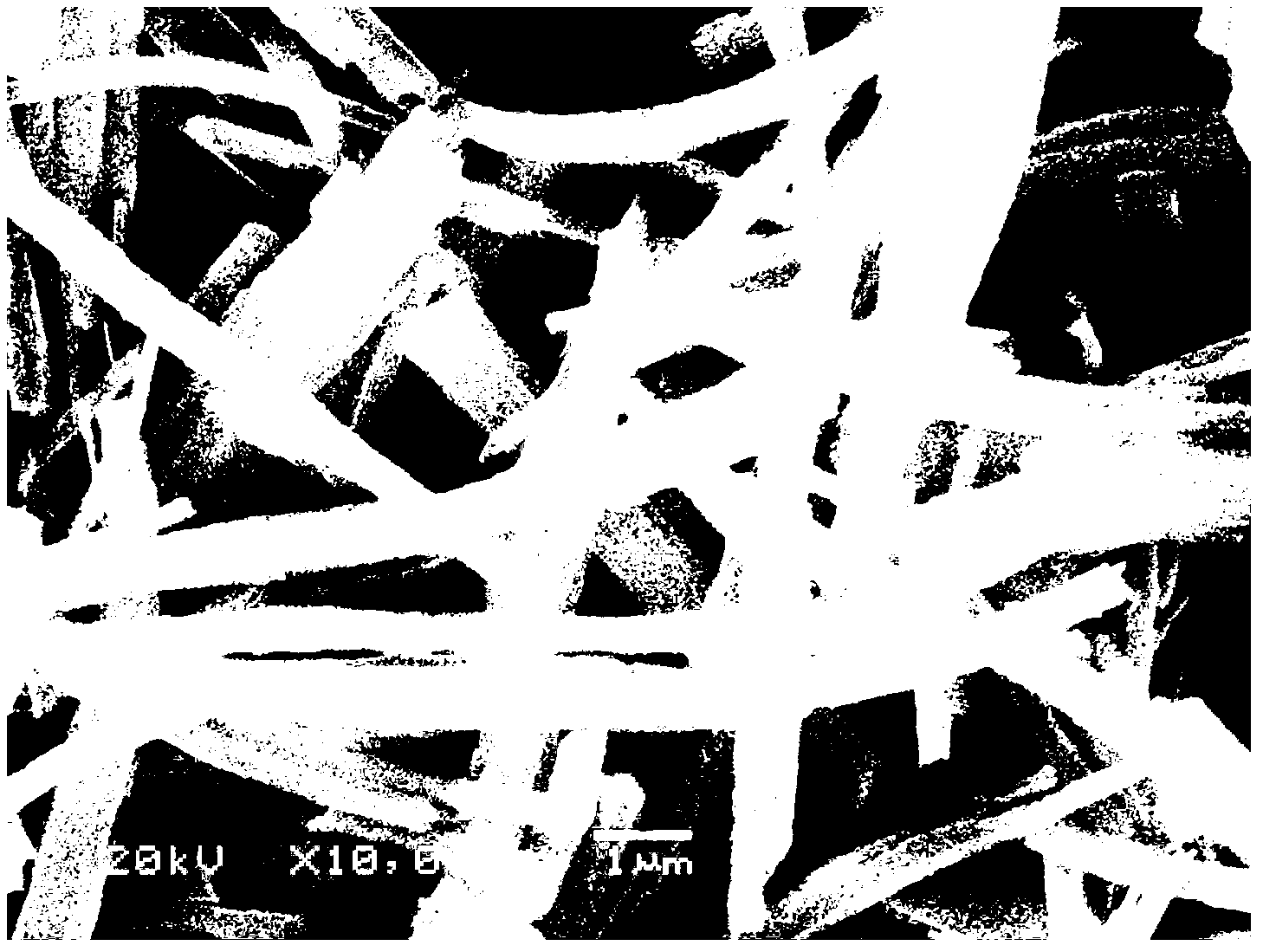

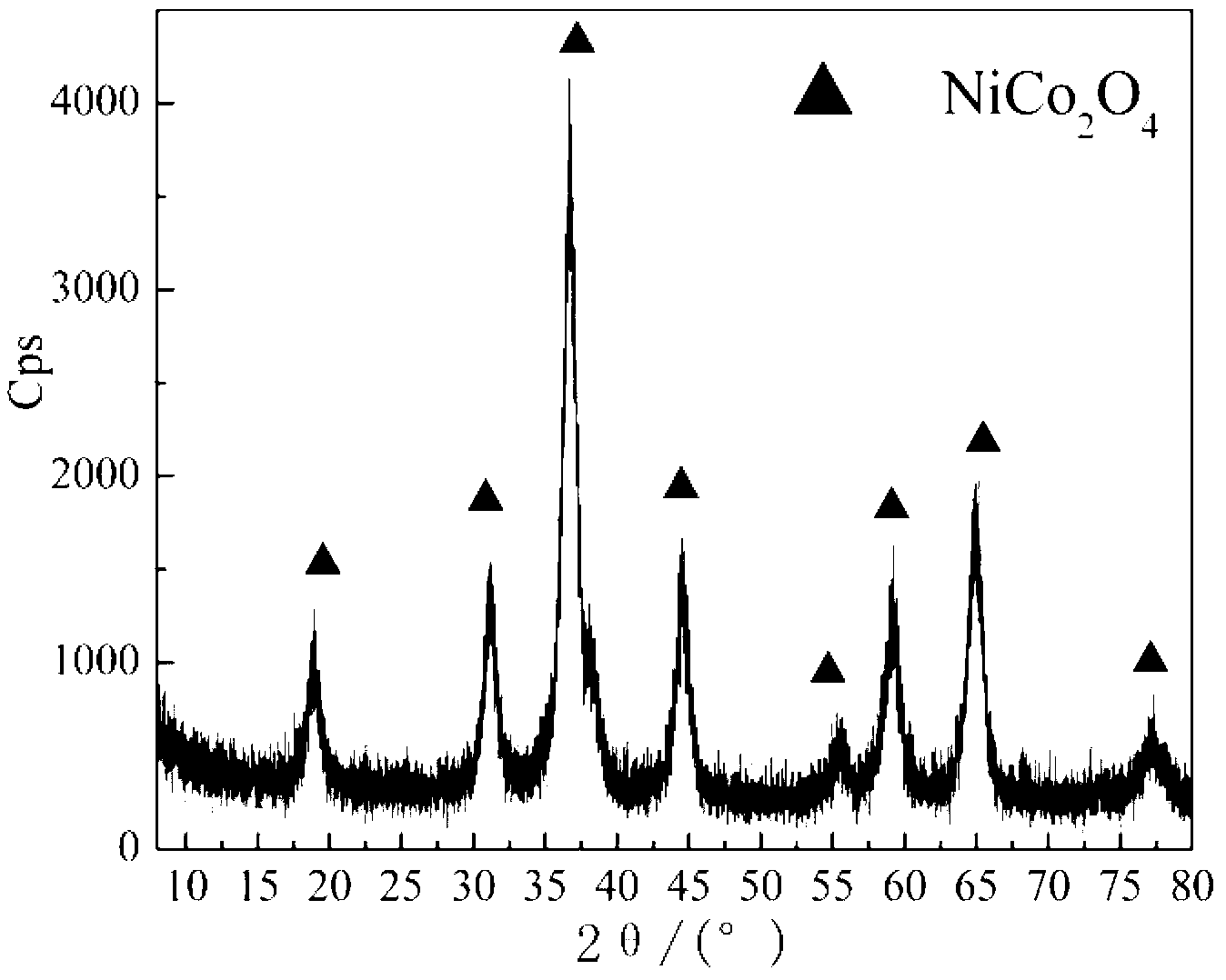

Image

Examples

Embodiment 1

[0039] 1) Weigh 0.02mol of NiCl with a purity of 98.0% respectively 2 ·6H 2 O and 0.04 mol purity of 99.0% CoCl 2 ·6H 2 O, NiCl 2 ·6H 2 O and CoCl 2 ·6H 2 The ratio of the amount of O substance is 1:2. NiCl 2 ·6H 2 O and CoC l2 ·6H 2 O was co-dissolved in 100ml deionized water and formulated to contain Ni 2+ and Co 2+ The mixed metal salt solution A100ml, the mixed metal salt solution A, Ni 2+ and Co 2+ The total concentration is 0.6mol / L.

[0040] 2) Dissolve 0.072mol of oxalic acid with a purity of 99% in a mixed solvent of 50ml of organic reagent ethanol and 50ml of deionized water. The organic reagent is ethanol with a purity of 99.7%, and configure it as oxalic acid solution B.

[0041] 3) Add 100ml of mixed metal salt solution A prepared in step 1 dropwise to 100ml of oxalic acid solution B prepared in step 2, stir while adding dropwise, while controlling the reaction temperature to 60°C, adjust the pH value with ammonia water, and keep the pH value 8.2, ...

Embodiment 2

[0045] Example 2: Electrode material prepared by mesoporous nickel cobaltate and its electrochemical characterization

[0046] A modified glassy carbon electrode was used as the working electrode. First, use 50nm alumina polishing powder to grind the glassy carbon electrode on a polishing cloth until the surface is smooth; then ultrasonically wash it three times in distilled water, and dry it for use. Take 0.05 g of the mesoporous nickel cobaltate powder prepared in Step Example 1, dissolve it in 2 mL of distilled water, and disperse evenly by ultrasonic; use a micro-sampler to draw 0.4 μL of sample, and apply it on the surface of the glassy carbon electrode. After drying at room temperature, 0.2 μL of Nafion solution (0.5 wt%) was applied to the surface of the sample. After drying at room temperature, a glassy carbon electrode modified with mesoporous nickel cobaltate was obtained, with a loading capacity of 0.5 mg / cm 2 .

[0047] The glassy carbon electrode modified by me...

Embodiment 3

[0051] 1) Weigh 0.02mol of NiCl with a purity of 98.0% respectively 2 ·6H 2 O and 0.04 mol purity of 99.0% CoCl 2 ·6H 2 O, the NiCl 2 ·6H 2 O and CoCl 2 ·6H 2 The ratio of the amount of O substance is 1:2. The NiCl 2 ·6H 2 O and CoCl 2 ·6H 2O, dissolved together in 100ml deionized water, formulated to contain Ni 2+ and Co 2+ 100ml of mixed metal salt solution A, the mixed metal salt solution A, Ni 2+ and Co 2+ The total concentration is 0.6mol / L.

[0052] 2) Dissolve 0.072mol of ammonium oxalate with a purity of 99.0% in a mixed solvent of 20ml of ethanol and 80ml of deionized water, the ethanol is ethanol with a purity of 99.7%, and configure as oxalate solution B.

[0053] 3) Add 100ml of mixed metal salt solution A prepared in step 1 dropwise to 100ml of oxalic acid solution B prepared in step 2), stir while adding dropwise, while controlling the reaction temperature to 60°C, adjust the pH value with ammonia water, and maintain the pH value is 8.0, after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com