Nano-superstructure polyporous material of ferrite and method of preparing the same

A porous material and superstructure technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve problems such as high cost and complicated preparation process, and achieve uniform particle size, uniform pore distribution, and easy process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

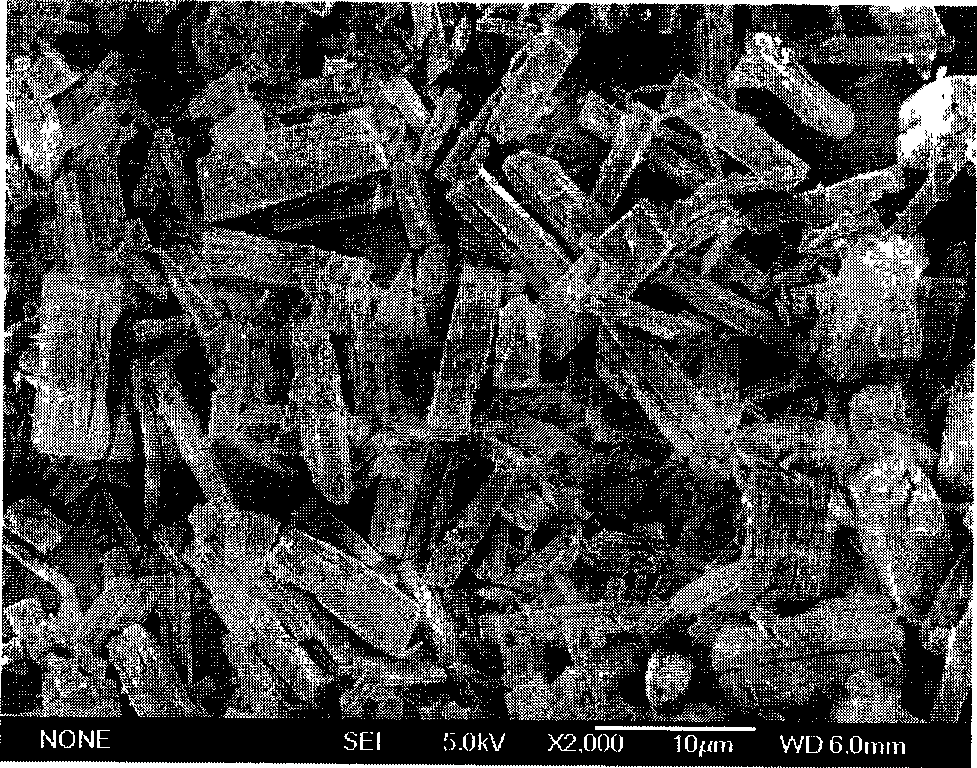

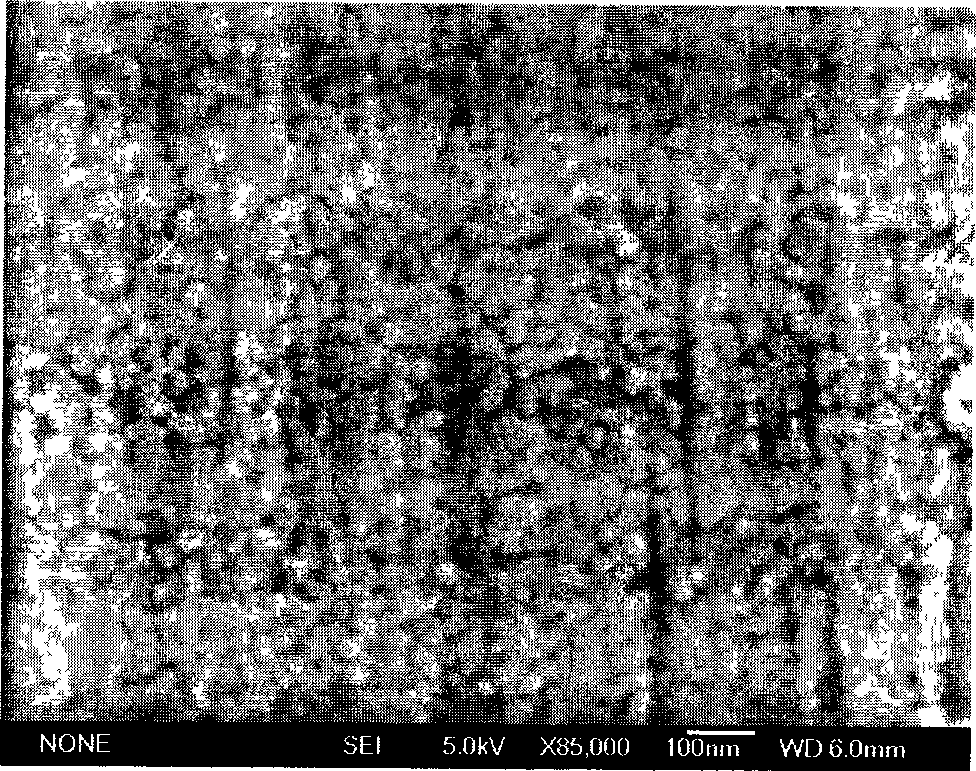

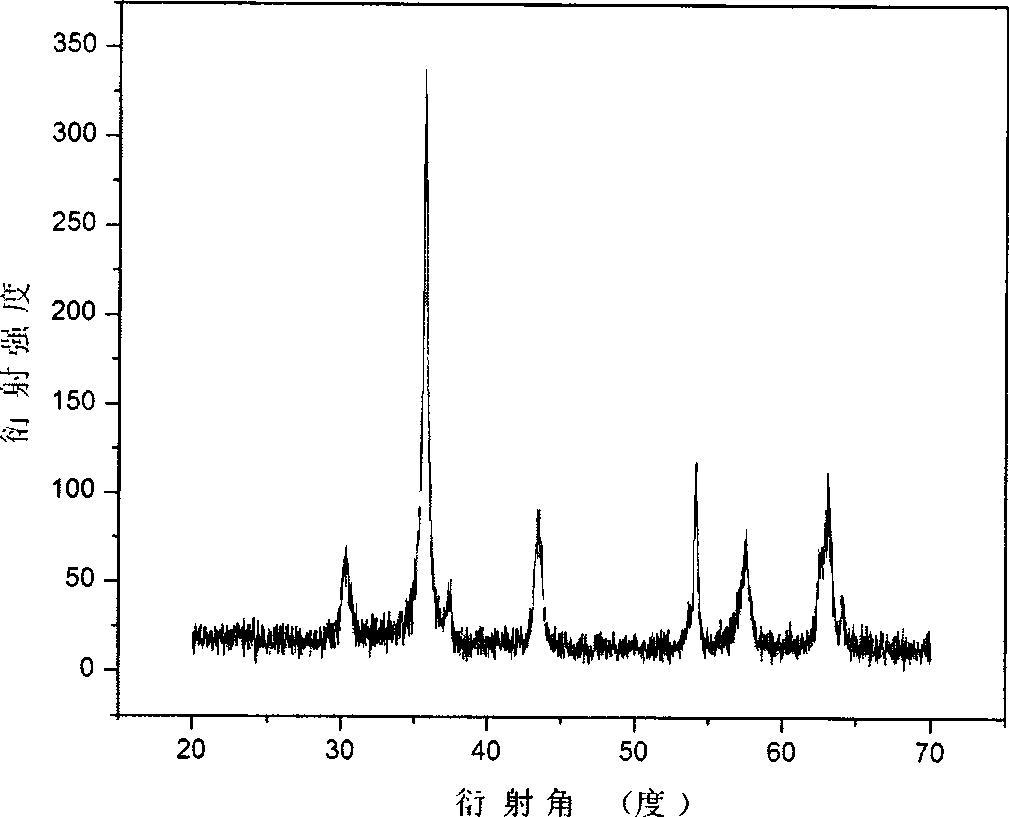

[0033] Preparation of nickel ferrite nano superstructure porous material, the preparation steps are:

[0034] Step 1, adopt soluble nickel sulfate as raw material, configure divalent nickel salt solution with distilled water, the content of nickel ion in the solution is 0.1mol / L;

[0035] Step 2, in another container, configure ferrous chloride solution with distilled water, the content of iron ion in the solution is 0.2mol / L;

[0036] Step 3. Heat the solutions obtained in step 1 and step 2 to 80°C respectively, and pour the solution obtained in step 2 into the solution obtained in step 1 while the solution obtained in step 1 is under stirring conditions, and set aside;

[0037] Step 4. In another container, prepare sodium oxalate solution with distilled water, the content of sodium oxalate in the solution is 0.5mol / L, and heat to 80°C;

[0038] Step 5, under the condition that the solution obtained in step 3 is stirred, pour the solution obtained in step 4 into the solution...

Embodiment 2

[0042] Preparation of nickel ferrite nano superstructure porous material, the preparation steps are:

[0043] Step 1, adopt soluble nickel nitrate as raw material, configure divalent nickel salt solution with distilled water, the content of nickel ion in the solution is 1mol / L;

[0044] Step 2, in another container, configure iron sulfate solution with distilled water, the content of iron ion in the solution is 2mol / L;

[0045] Step 3. Heat the solutions obtained in step 1 and step 2 to 100°C respectively, and pour the solution obtained in step 2 into the solution obtained in step 1 while the solution obtained in step 1 is under stirring conditions, and set aside;

[0046] Step 4. In another container, prepare a sodium oxalate solution with distilled water, the content of sodium oxalate in the solution is 1mol / L, and heat to 100°C;

[0047] Step 5, under the condition that the solution obtained in step 3 is under stirring, pour the solution obtained in step 4 into the solutio...

Embodiment 3

[0051] Preparation of nickel ferrite nano superstructure porous material, the preparation steps are:

[0052] Step 1, adopt soluble nickel chloride as raw material, configure divalent nickel salt solution with distilled water, the content of nickel ion in the solution is 0.5mol / L;

[0053] Step 2, in another container, configure ferric chloride solution with distilled water, the content of iron ion in the solution is 1mol / L;

[0054] Step 3. Heat the solutions obtained in step 1 and step 2 to 80°C respectively, and pour the solution obtained in step 2 into the solution obtained in step 1 while the solution obtained in step 1 is under stirring conditions, and set aside;

[0055] Step 4. In another container, prepare sodium oxalate solution with distilled water, the content of sodium oxalate in the solution is 0.5mol / L, and heat to 80°C;

[0056] Step 5, under the condition that the solution obtained in step 3 is stirred, pour the solution obtained in step 4 into the solution o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com