Preparation method of high-specific-surface CuMn2O4 catalyst for CO low-temperature oxidation removal

A technology of high specific surface area and catalyst, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc. Chemical industry production, problems affecting catalyst activity and stability, etc., to achieve the effect of low cost, short time consumption and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

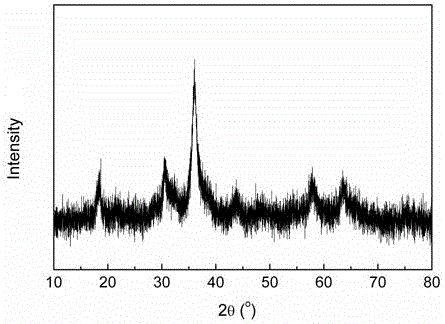

[0015] Weigh 10mmol of copper acetate and 20mmol of manganese acetate and dissolve them in 100mL of deionized water to prepare a mixed solution with a total molar concentration of about 0.3mol / L, and quickly add 100mL of the solution with a molar concentration of 0.3mol / L under the conditions of ultrasonic assistance and strong stirring. L ammonium oxalate solution, gradually a light blue precipitate formed. Wherein the ultrasonic power is 50W, and the rotational speed of the stirrer is 800r / min. After continuing to stir for 40 min, the precipitate was filtered and washed three times with absolute ethanol, and then dried at 60° C. for 24 h to obtain a copper manganese oxalate precursor. Then the CuMn oxalate precursor was ground and then heated to 300 °C in the air for 2 h (heating rate 1 °C / min), and finally the spinel CuMn 2 o 4 Catalyst (if attached figure 1 shown), its specific surface area is 109m 2 / g.

[0016] The catalyst needs to be made into 40-60 mesh particles...

Embodiment 2

[0020] Weigh 10mmol of copper nitrate and 20mmol of manganese nitrate and dissolve them in 100mL of deionized water to prepare a mixed salt solution with a total molar concentration of about 0.3mol / L. Under the conditions of ultrasonic assistance and strong stirring, quickly add 60mL of / L of ammonium oxalate solution, a light blue precipitate gradually formed. Wherein the ultrasonic power is 80W, and the rotational speed of the stirrer is 1200r / min. After continuing to stir for 60 min, the precipitate was filtered and washed three times with absolute ethanol, and then dried at 80° C. for 12 h to obtain a copper manganese oxalate precursor. Then the CuMn oxalate precursor was ground and then heated to 400 °C in air for 1 h (heating rate was 2 °C / min), and finally the spinel CuMn 2 o 4 Catalyst with a specific surface area of 100m 2 / g.

[0021]Catalyst treatment and activity evaluation methods are the same as in Example 1, but the CO content in the feed gas is 2000ppm, a...

Embodiment 3

[0023] Weigh 14mmol of copper acetate and 28mmol of manganese acetate and dissolve them in 100mL of deionized water to prepare a mixed solution with a total molar concentration of about 0.42mol / L. Under the conditions of ultrasonic assistance and strong stirring, 140mL of L ammonium oxalate solution, gradually a light blue precipitate formed. Wherein the ultrasonic power is 70W, and the rotational speed of the stirrer is 900r / min. After continuing to stir for 45 min, the precipitate was filtered and washed three times with absolute ethanol, and then dried at 70° C. for 20 h to obtain a copper manganese oxalate precursor. Then the copper manganese oxalate precursor was ground and then heated to 350 °C in air and roasted for 3 h (heating rate was 0.5 °C / min) to obtain spinel CuMn 2 o 4 Catalyst with a specific surface area of 104m 2 / g.

[0024] Catalyst treatment and activity evaluation methods are the same as in Example 1, but the content of CO in the feed gas is 500ppm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com