Process for recovering rare earth oxide, process for producing abrasive containing rare earth oxide and polishing method using abrasive

A technology of rare earth oxides and rare earth hydroxides, which is applied in the fields of rare earth metal compounds, chemical instruments and methods, and inorganic chemistry, and can solve problems such as impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] Embodiment 1 (recover rare earth oxide from abrasive waste liquid)

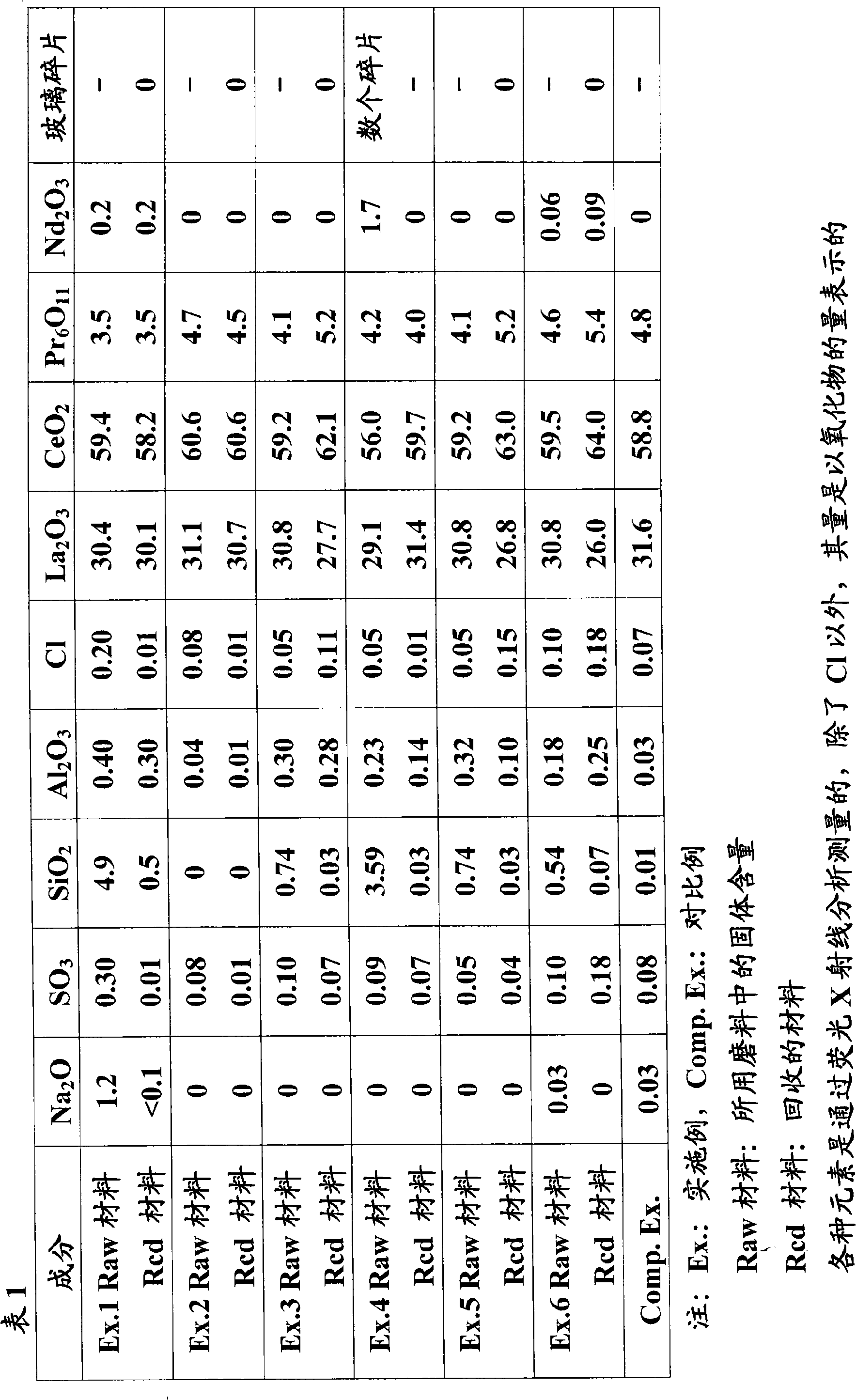

[0137] Rare earth oxides were recovered from abrasive waste liquids having solid components shown in Table 1, which were generated when glass dishes were polished, by the following procedure.

[0138] In 1 liter of abrasive waste liquid, adding 38 g concentration is 20 mass % aluminum sulfate aqueous solution and 0.2 g polymeric flocculant (KuriflocTM ; available from Kurita Water Industries Ltd.) and mixed to aggregate and deposit the solid ingredients. Separate and recover the sediment.

[0139] Then, 100 g of the recovered solid was put into a beaker containing 262 g of concentrated sulfuric acid having a concentration of 95% by mass, and the mixture was stirred for 5 minutes. The beaker was heated to 100°C, and the organic material was decomposed by the dehydration action of hot sulfuric acid, producing a black liquid. 20 g of aqueous hydrogen peroxide was added dropwise thereto, thereby removing...

Embodiment 2

[0144] Example 2 (Recovery of Rare Earth Oxide from Abrasive Waste Liquid)

[0145] Powdery rare earth oxides were recovered from abrasive waste liquids having solid components shown in Table 1, which were generated when optical filters were polished, by the following steps.

[0146] 100 g of the recovered powder was added to a SUS beaker containing 245 g of aqueous sulfuric acid having a concentration of 98% by mass, and the mixture was stirred with a SUS spatula. The beaker was then covered with a watch glass, placed on a heater, heated at 600W for 30 minutes, and allowed to cool.

[0147] The obtained yellow solid (rare earth sulfate) was placed in a mortar and crushed with a pestle. Another 1 liter of cold water was placed in a beaker surrounded by ice water and stirred. To this ice water was gradually added the crushed material obtained above and mixed to prepare an acidic sulfate solution containing rare earth sulfate (brown transparent solution). The rare earth sul...

Embodiment 3

[0153] Example 3 (Recovery of Rare Earth Oxide from Abrasive Waste Liquid)

[0154] Rare earth oxides were recovered from abrasive waste liquids having solid components shown in Table 1, which were generated when polishing glass substrates for hard disks, by the following steps.

[0155] 0.5 liter of abrasive waste liquid containing 100 g of solid content and 250 g of hydrochloric acid with a concentration of 35% by mass were put into a flask equipped with a water-cooled tube. This content was heated and maintained at a temperature of 103°C. The vapors emitted by heating are cooled by water-cooled tubes and sent back to the flask so that the liquid surface does not lower. When the contents were heated for 48 hours, the abrasive waste liquid became a mixed liquid consisting of a green acidic aqueous solution containing rare earth chlorides, white silica gel and insoluble materials such as polishing pad fragments.

[0156] The water-cooled tube was removed from the flask, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com