Method for preparing silica antireflective film

A technology of silicon dioxide and anti-reflection coatings, which is applied in the direction of instruments, coatings, optics, etc., can solve the problems of poor repeatability and controllability of the refractive index of anti-reflection coatings, and achieve simple, controllable and high repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

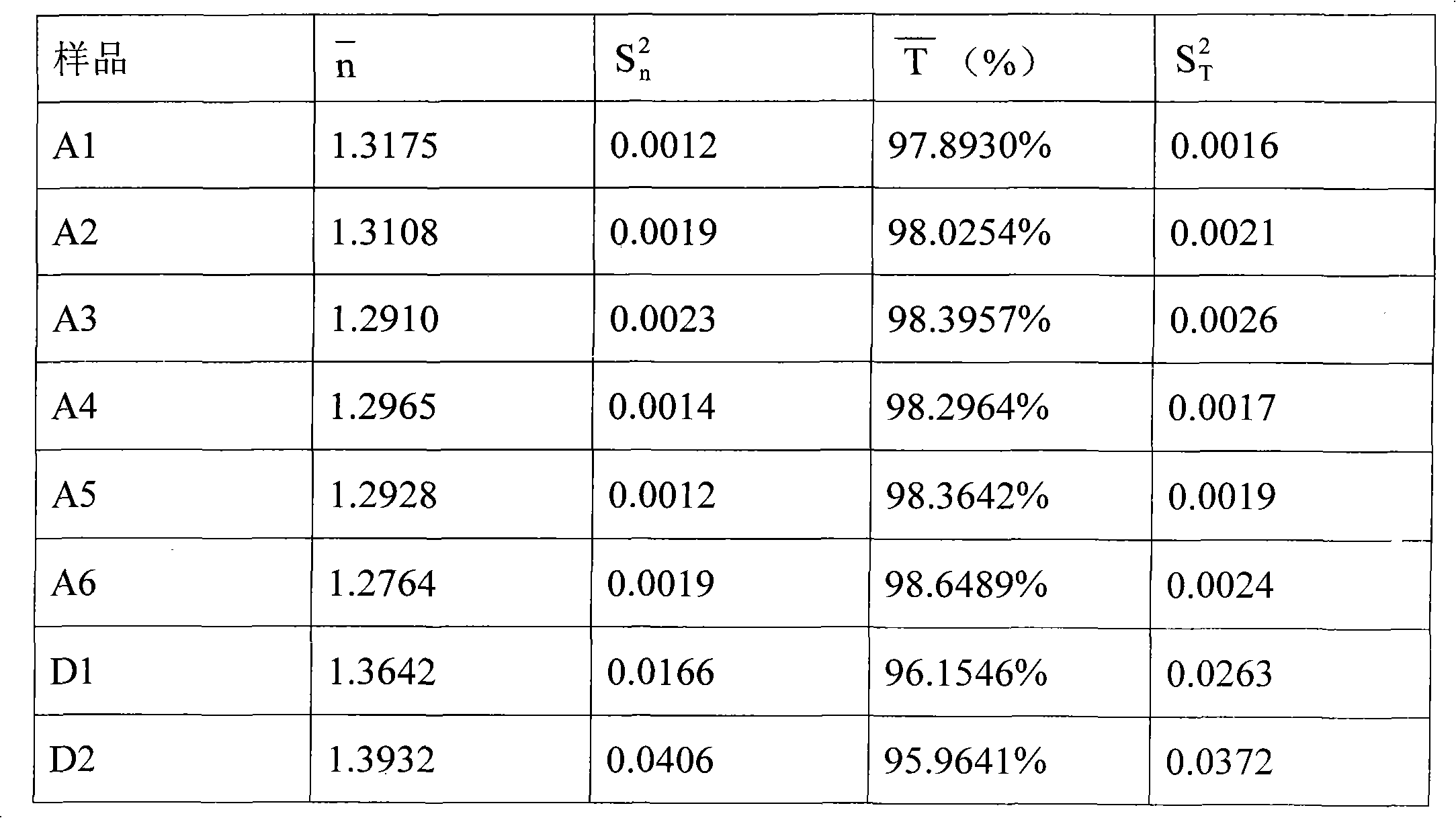

Examples

preparation example Construction

[0009] The invention provides a kind of preparation method of silicon dioxide anti-reflection film, comprises the following steps:

[0010] a) Mix the system containing tetraethyl orthosilicate and absolute ethanol evenly, and obtain silica sol by sol-gel method under alkaline conditions; the system also contains soluble carbonate, bicarbonate, lemon One or more of tartrates, tartrates and oxalates;

[0011] b) using the silica sol obtained in step a) to coat a film and perform heat treatment to obtain the silica anti-reflection film.

[0012] In the present invention, the silica sol is prepared by the sol-gel method commonly used by those skilled in the art. The sol-gel method comprises: uniformly mixing a system containing ethyl orthosilicate and absolute ethanol, and hydrolyzing the ethyl orthosilicate under alkaline conditions to obtain the silica sol.

[0013] Based on the total mass of the system, the content of ethyl orthosilicate is 5-20wt%, and the content of absolu...

Embodiment 1

[0026] (1) Take 20g of ammonium bicarbonate and dissolve it in 100g of deionized water to prepare a 0.2g / mL ammonium bicarbonate solution;

[0027] (2) Disperse 6.25g of tetraethyl orthosilicate in 60mL of absolute ethanol, add 1g of ammonia water, then add 1.5mL of the ammonium bicarbonate solution in step (1), stir at room temperature for 8h, age for 5d, reflux and stir in a water bath at 50°C 4h, then add 5mL PEG400 to obtain silica sol;

[0028] (3) After aging the silica sol in step (2) for 2 days, by pulling the coating film, it was placed on a 25.4mm×76.2mm×1.2mm microscope slide (refractive index 1.5146, light transmittance 91.1911%) ) coated with the silica sol, the amount of sol is 0.0052g / cm 2 ; Transfer to an oven, bake at 200°C for 1h, and sinter at 390°C for 3h.

[0029] Through the above steps, the glass sample with the anti-reflection film of this embodiment attached on the surface was obtained, which was denoted as A1.

Embodiment 2

[0031] Adopt the method identical with embodiment 1 to prepare glass sample, difference is:

[0032] In step (1), take by weighing 10g salt of wormwood and be dissolved in 100g deionized water, be mixed with the potassium carbonate solution of 0.1g / mL; In step (2), replace the bicarbonate in embodiment 1 with the potassium carbonate solution of 1.2mL ammonium solution.

[0033] A glass sample was obtained through the above steps, denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com