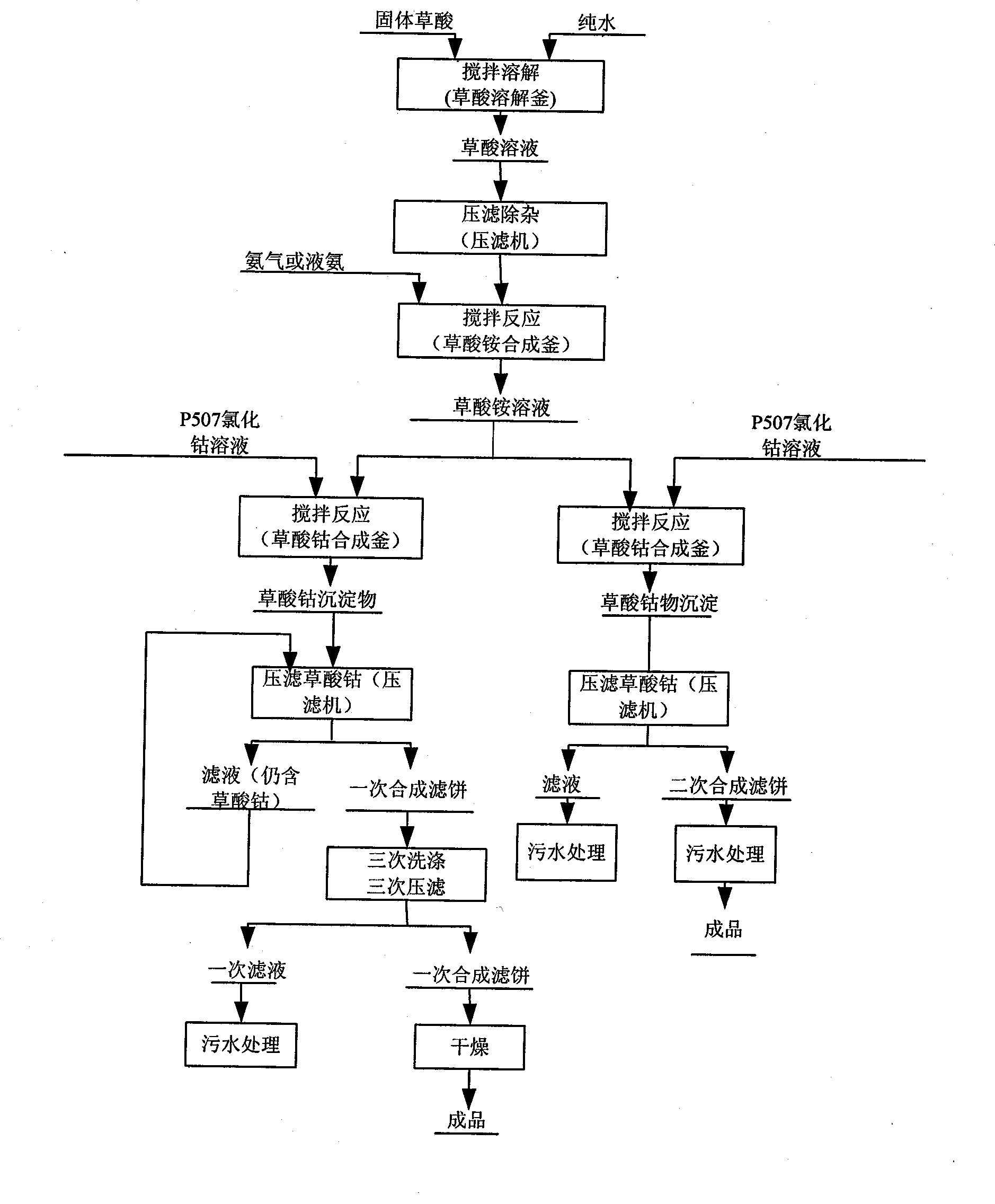

Cobalt oxalate coarseness prediction technique in hydrometallurgy synthesis course

A synthesis process and hydrometallurgy technology, applied in the direction of electrical program control, comprehensive factory control, instruments, etc., can solve problems such as difficulty in meeting production requirements, large lag in manual testing, and difficult quality control of testing values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

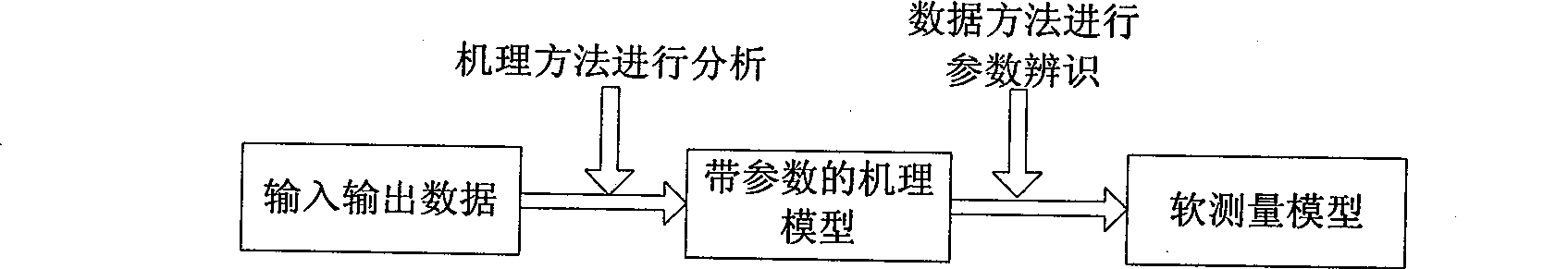

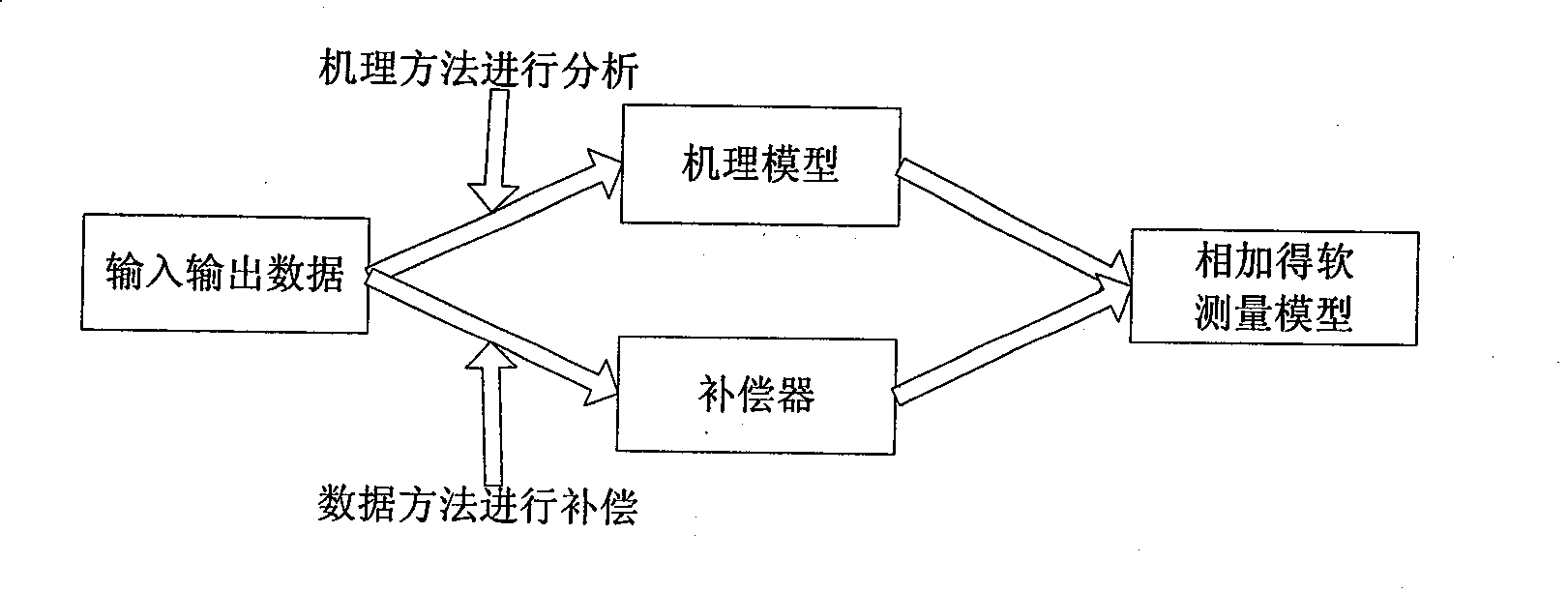

Method used

Image

Examples

Embodiment 1

[0204] Implementation of particle size prediction method on cobalt oxalate (fines) production line.

[0205] The specific implementation process is as follows:

[0206] 1) Auxiliary variable selection: The selection of auxiliary variables is the first step in establishing the soft sensor model. This step determines the input information matrix of the soft sensor, thus directly determining the structure and output of the soft sensor model. It is crucial. The selection of auxiliary variables includes the selection of variable type, the selection of variable number and the selection of detection point location.

[0207] During the synthetic process of cobalt oxalate, we select temperature (T), stirring speed (Np), cobalt chloride concentration (CB) and ammonium oxalate flow rate (V B ) is an auxiliary variable.

[0208] 2) Data collection and processing: Data collection was carried out at the site of the synthetic cobalt oxalate process. The specific measuring instruments are...

Embodiment 2

[0223] Implementation of the particle size prediction method on a cobalt oxalate (coarse material) production line.

[0224] With above-mentioned embodiment 1, first consider the situation of each position of production line, collect the data on the coarse material production line and then go through the following main modeling steps: 1) auxiliary variable selection; 2) data acquisition and processing; 3) simplified mechanism model calculation; 4 ) mixed model predictive calculation.

[0225] The cobalt oxalate (coarse material) particle size prediction model established according to this modeling method has been used in a cobalt oxalate production unit in a factory. In order to illustrate the effectiveness of the model, the calculated data were compared with the laboratory analysis values. The laboratory has 2 batches of average particle size test values per day, and a total of 25 valid data were collected (with parking during the period). The curve comparison between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com