Solid-state battery and preparation method and application thereof

A solid-state battery and solid-state technology, applied in battery electrodes, lithium batteries, secondary batteries, etc., can solve problems such as poor cycle performance and poor electrochemical performance, and achieve high conductivity, charge and discharge capacity, high first effect, and high capacity Good retention rate and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

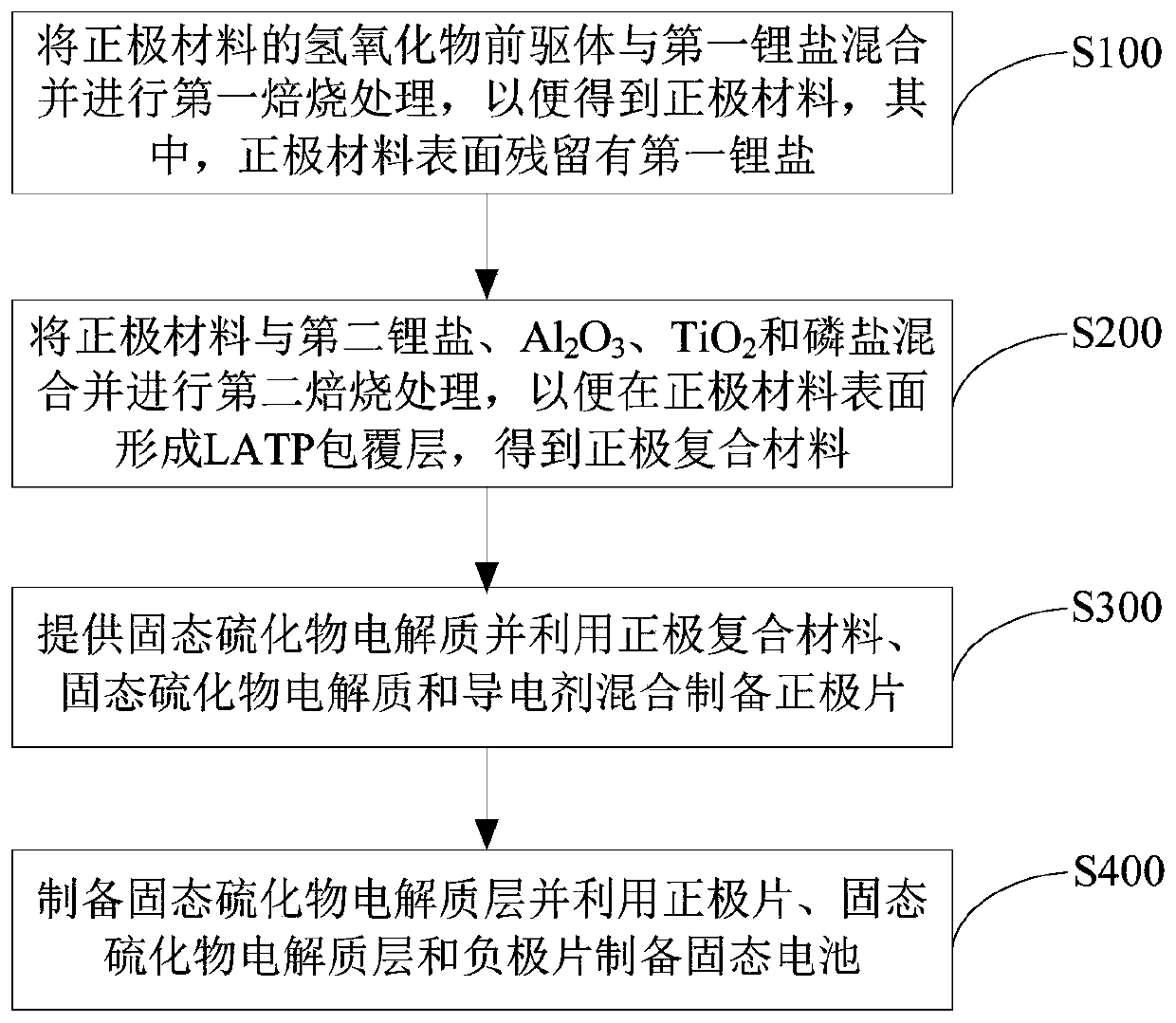

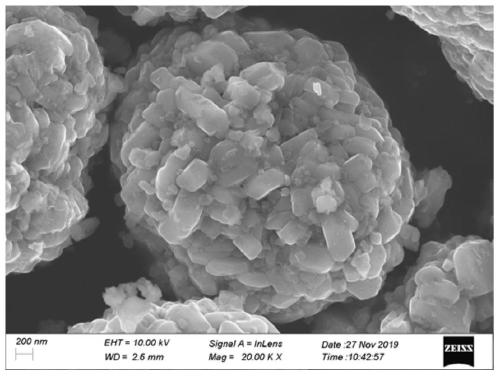

[0108] (1) Synthesis of Ni by hydroxide coprecipitation method 0.83 co 0.08 mn 0.09 (OH) 2 For the precursor, lithium hydroxide was mixed with the precursor at a molar ratio of 1.05:1, and then the mixture was calcined at 750° C. for 10 hours, and the obtained positive electrode material was named NCM-811. After the calcined powder material is ground by a mortar or an ultra-centrifugal grinder until the particle size is less than 3 μm, the sample is tested for residual alkali content, and the test result shows that the residual lithium salt content is 0.07 mol%, which is used as Subsequent in situ generation of directing agent for LATP coating layer;

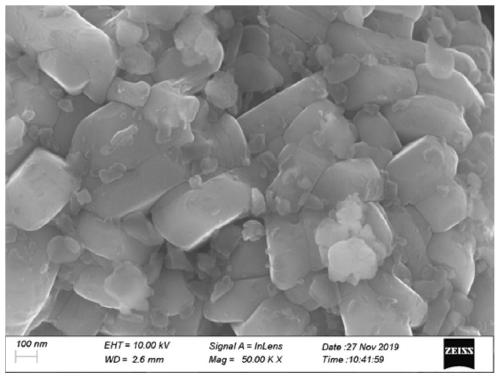

[0109] (2) Weigh 100g of the positive electrode material obtained in step (1), and weigh Li 2 CO 3 (0.18g) as the second lithium salt, Al 2 o 3 (0.02g), TiO 2 (0.35g) and (NH 4 ) 3 PO 4 (1.15g), where Li 2 CO 3 、Al 2 o 3 、TiO 2 and (NH 4 ) 3 PO 4 Has been ground to nanoparticles (2 CO 3 、Al 2 o 3 、TiO 2 an...

Embodiment 2

[0115] (1) Synthesis of Ni by hydroxide coprecipitation method 0.83 co 0.08 mn 0.09 (OH) 2 For the precursor, lithium hydroxide was mixed with the precursor at a molar ratio of 1.05:1, and then the mixture was calcined at 750° C. for 10 hours, and the obtained positive electrode material was named NCM-811. After the calcined powder material is ground by a mortar or an ultra-centrifugal grinder until the particle size is less than 3 μm, the sample is tested for residual alkali content, and the test result shows that the residual lithium salt content is 0.07 mol%, which is used as Subsequent in situ generation of directing agent for LATP coating layer;

[0116] (2) Weigh 100g of the positive electrode material obtained in step (1), and weigh Li 2 CO 3 (0.18g) as the second lithium salt, Al 2 o 3 (0.02g), TiO 2 (0.35g) and (NH 4 ) 3 PO 4 (1.15g), where Li 2 CO 3 、Al 2 o 3 、TiO 2 and (NH 4 ) 3 PO 4 Has been ground to nanoparticles (2 CO 3 、Al 2 o 3 、TiO 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com