Dust collector used for airflow micronizer

The technology of a dust removal device and a micropowder machine is applied in the fields of removing smoke and dust, cleaning methods and utensils, and grain processing. The effect of increasing the vacuuming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

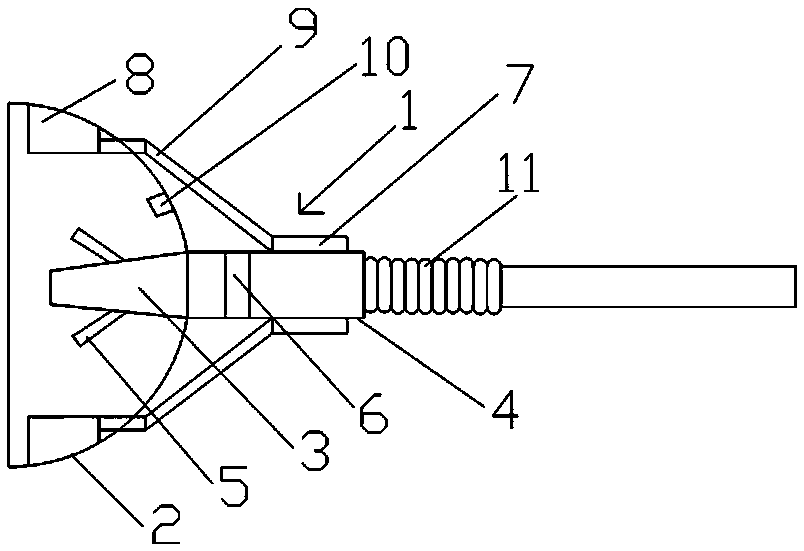

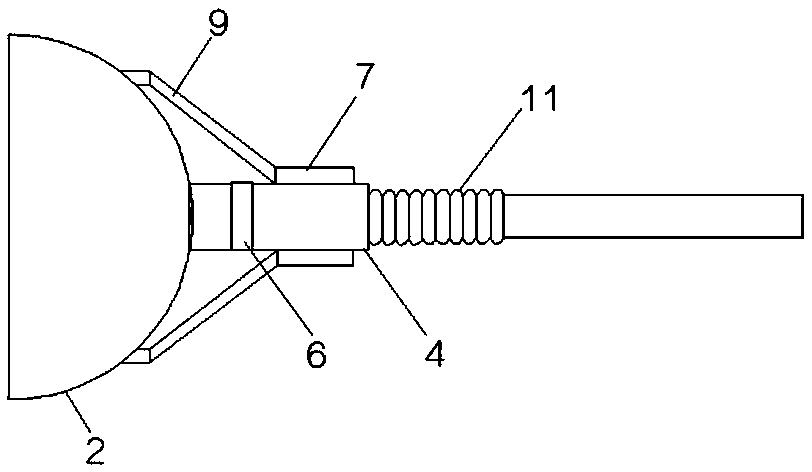

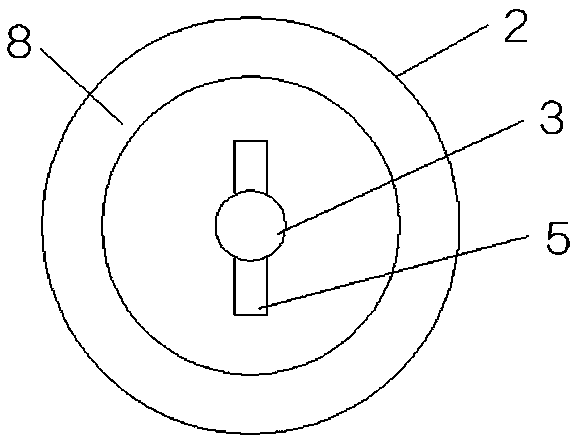

[0019] Such as figure 1 As shown, a dust removal device for an airflow micro-powder machine includes a dust removal mechanism 1 and a dust cover 2, the dust removal mechanism 1 is fixedly connected with the dust cover 2, and the dust removal mechanism 1 includes a dust suction pipe 3, a pipe body 4 and The air outlet device 7, the side of the dust suction pipe 3 is provided with an auxiliary dust suction pipe 5, the filter screen 6 is arranged in the pipe body 4, the air outlet device 7 is arranged on the side of the pipe body 4, and the air outlet device 7 is fixedly connected with the pipe body 4, the dust cover 2 is provided with an air outlet 8, and the air outlet 8 is provided with an air outlet pipe 9, and the air outlet pipe 9 is fixedly connected with the air outlet device 7, the A dust detection device 10 is arranged inside the dustproof cover 2 , and a telescopic pipe 11 is arranged at the upper end of the pipe body 4 .

[0020] More than one auxiliary dust suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com