Power-driven vacuum pump for car braking system

An automobile brake system, electric vacuum pump technology, applied to parts of pumping devices for elastic fluid, pump parts of rotary piston type/oscillating piston type, pumps, etc., can solve frictional heat reduction, high noise, and low Vacuum pumping efficiency and other issues, to achieve the effect of increased ultimate vacuum, reduced noise, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

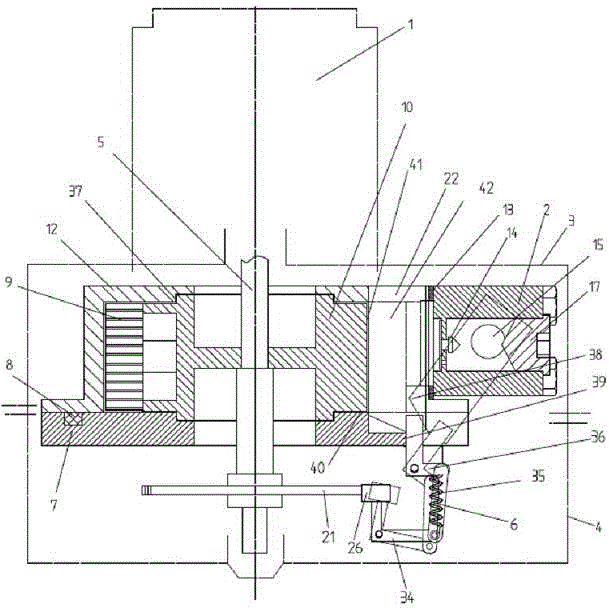

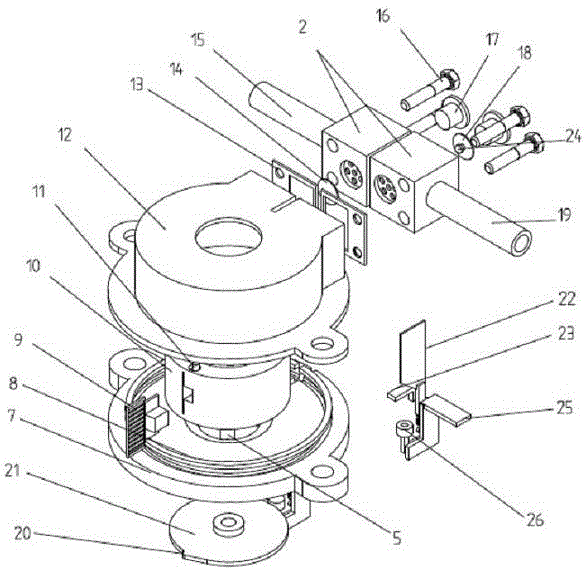

[0032] Including the motor 1, there are a pump body assembly, a one-way valve assembly, a cam 21, and a connecting rod assembly in the lower casing 4 and the upper casing 3;

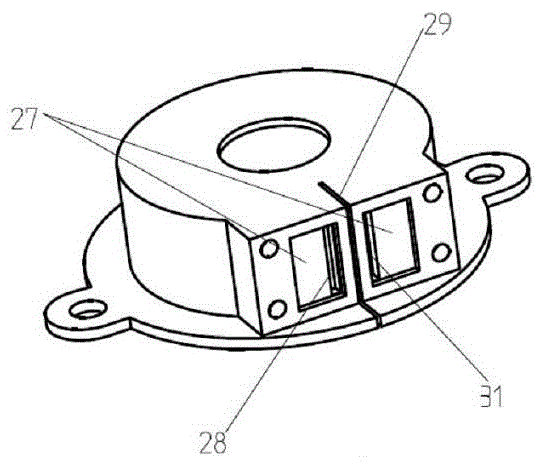

[0033] The pump body assembly is composed of an upper cover plate 12, a lower cover plate 7, a sealing ring 8, a rotor 10, blades 9, screws 11, and a rotor shaft 5. There is a hole in the middle of the upper cover plate 12, and there is an annular step inside the edge of the hole. -37, the upper cover plate 12 is radially opened with a through groove 29, the radial depth does not exceed the outer edge of the rotor 10 in the assembled state, the upper end surface of the lower cover plate 7 is opened with an annular groove near the outer edge, and a rectangular sealing ring with a gap 8 Installed in the groove, there is a hole in the middle of the lower cover plate 7, and the inner side has an annular step 2 40, and the lower cover plate 7 is radially opened with a limit groove 39, and the limit groove 39 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com