Coil-type forming device of mosquito incense piping

A forming device, incense plate technology, applied in the direction of winding strip, transportation and packaging, thin material processing, etc., can solve the problems of easy damage to the shaft of the forming roller, affecting production efficiency, wasting time and pipe material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

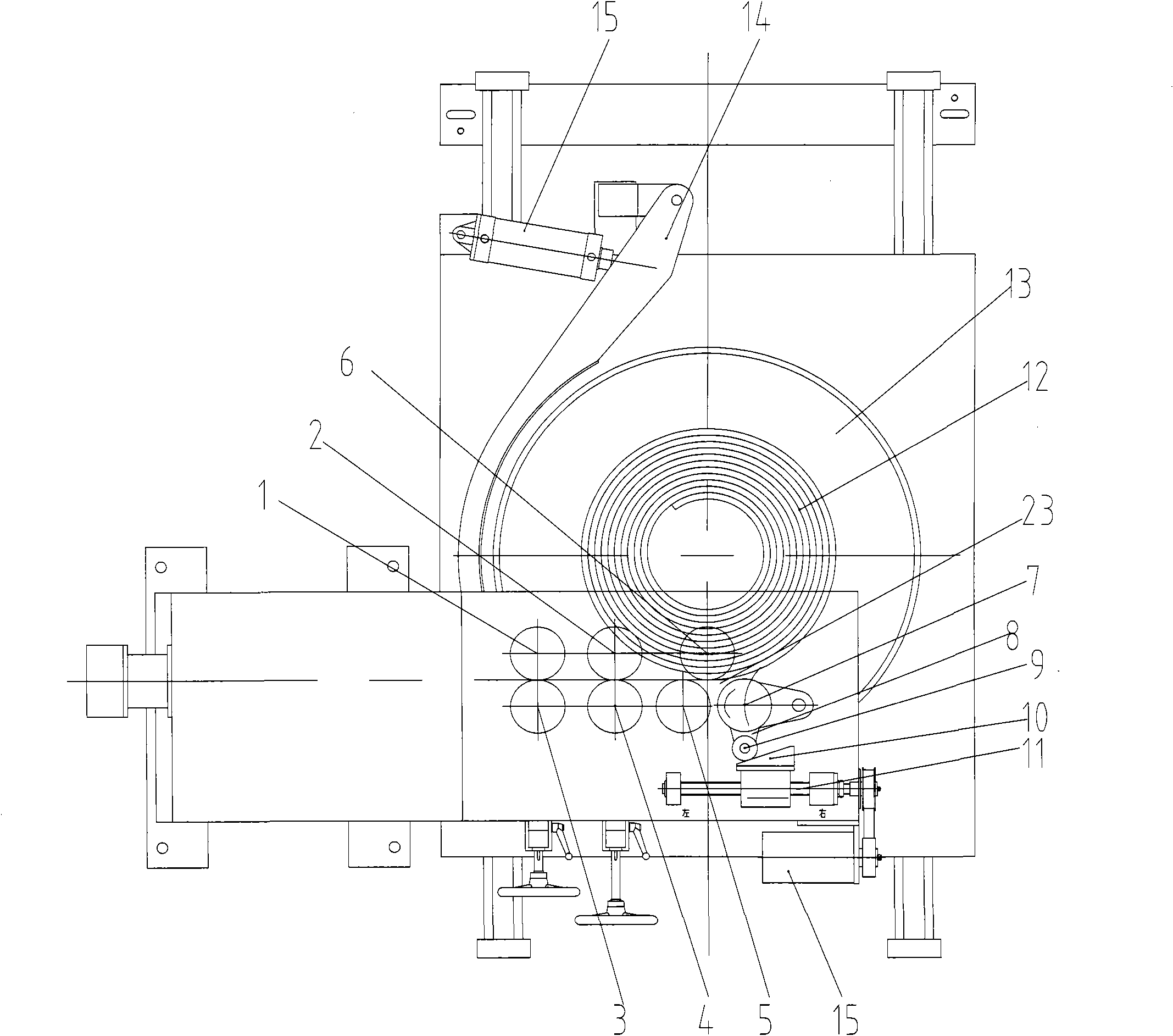

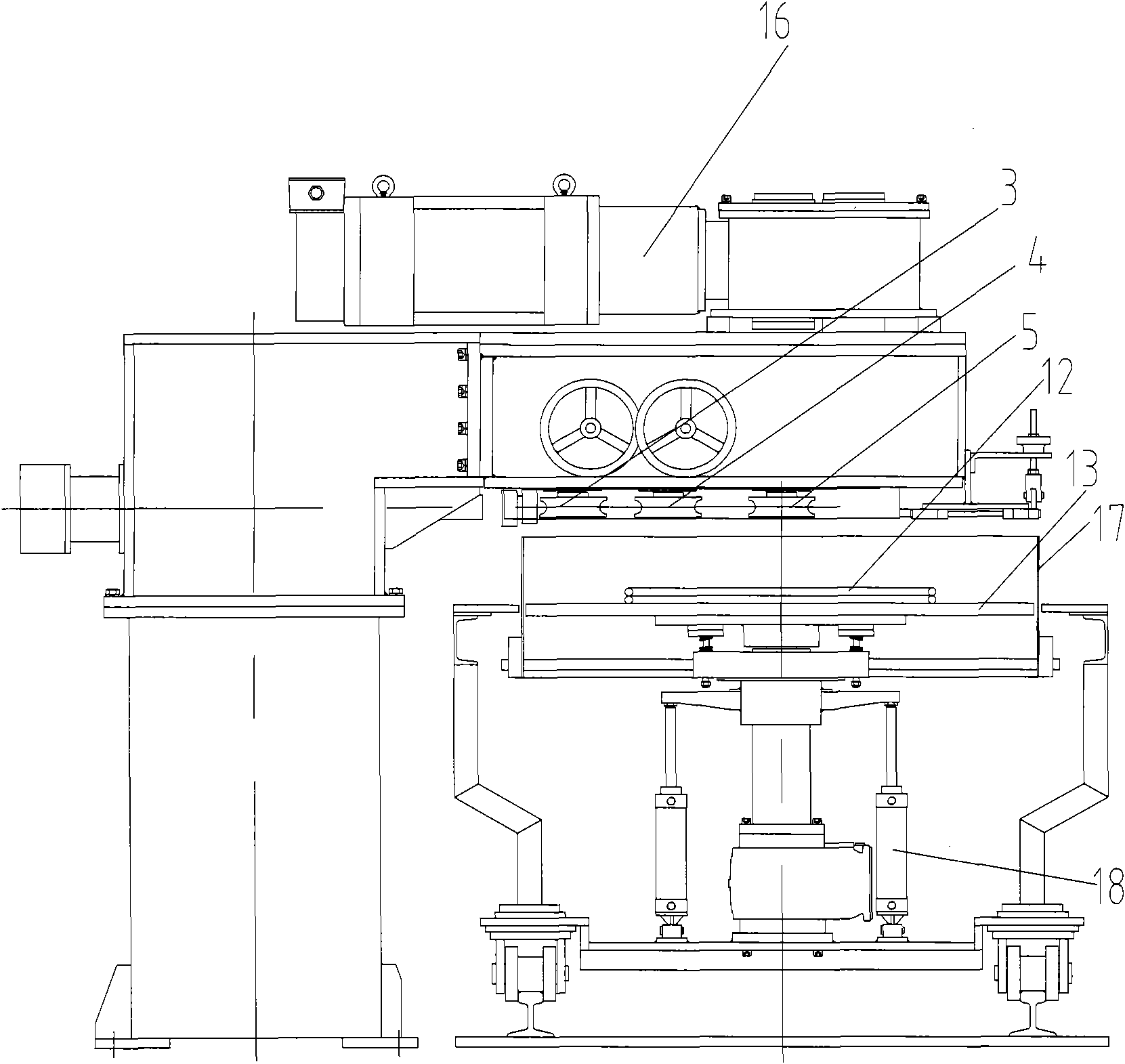

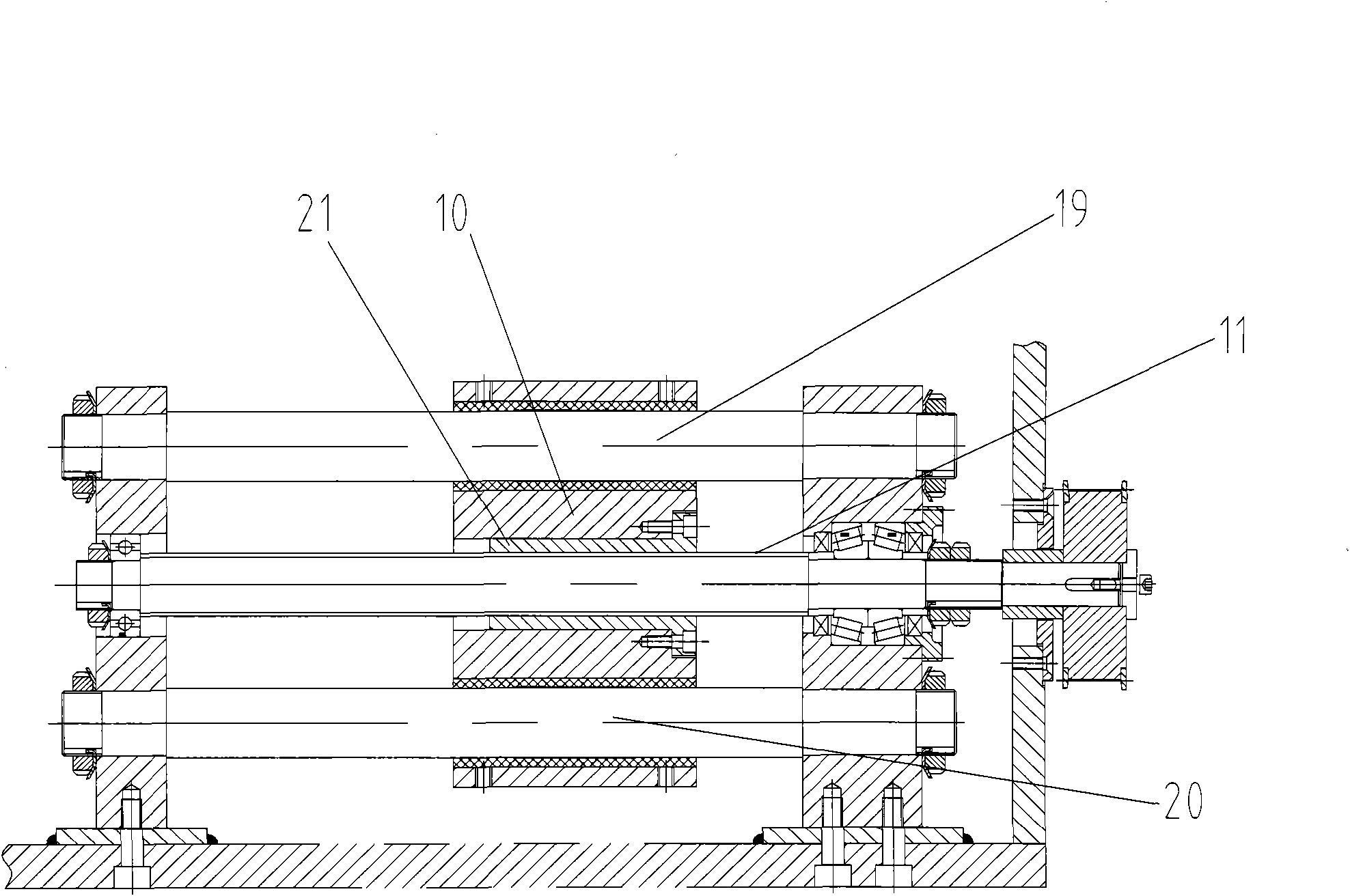

[0013] see figure 1 As shown, the mosquito-repellent coil forming device includes pinch rollers 1, 2, 3, 4, 5, 6 for pinching pipes, and also includes pinch rollers 1, 2, 3, 4, 5, and 6 downstream The forming roller 7 used for bending the pipe, the forming roller 7 is fixed on the rotating seat 8 and can rotate itself, the pinch roller 1 and the pinch roller 3 are arranged at intervals, the pinch roller 2 and the pinch roller 4 are arranged at intervals, and the pinch roller 4 is arranged at intervals. The feed roller 5 and the pinch roller 6 are arranged at intervals, but the pinch roller 6 is slightly offset and arranged between the pinch roller 5 and the forming roller 7, and the pinch roller 6 and the forming roller 7 cooperate to form a curved channel for the curved pipe 23. In addition, a rolling member 9 is set on the rotating seat 8, and the rolling member 9 is in rolling contact with the inclined surface of the inclined slider 10. The lower part of the inclined slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com