Stator wire embedding mold and stator wire embedding device

A technology for inserting wire molds and stators, which is used in electromechanical devices, manufacturing motor generators, and electrical components, etc., can solve the problems of decreased insulation performance of enameled wires, higher requirements for manual skills, and scrapped motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

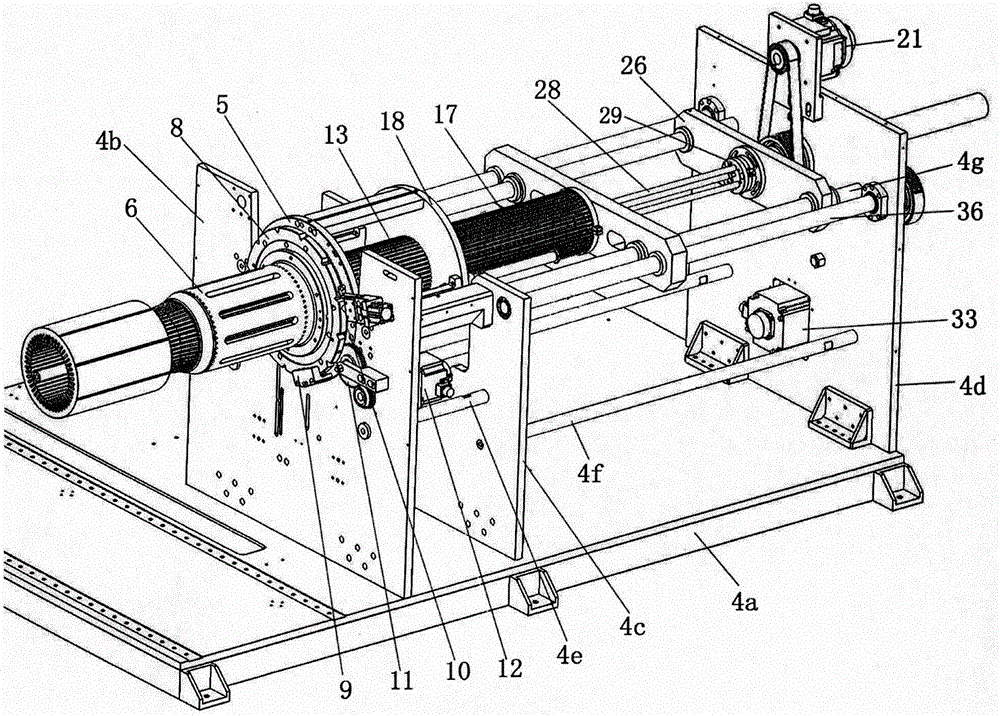

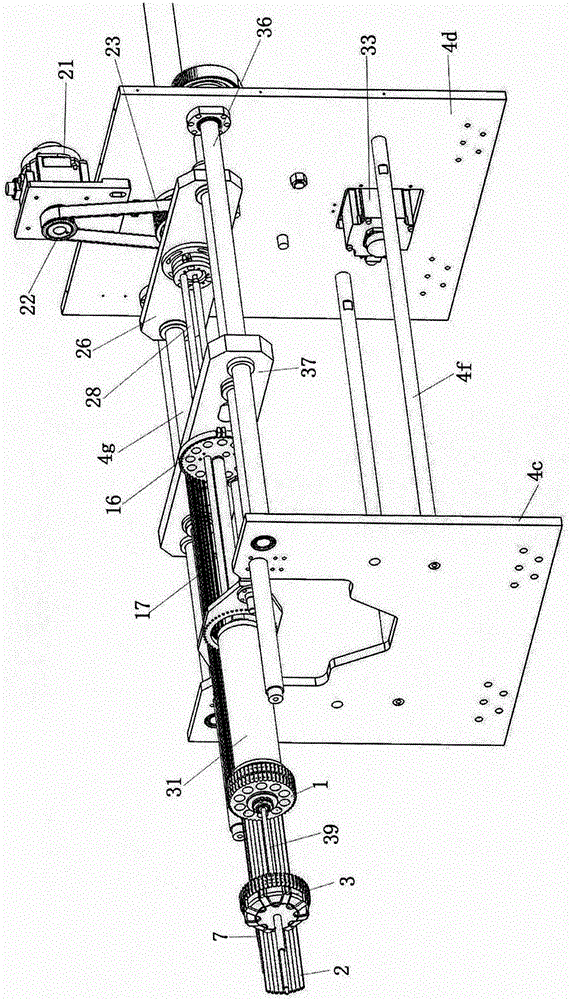

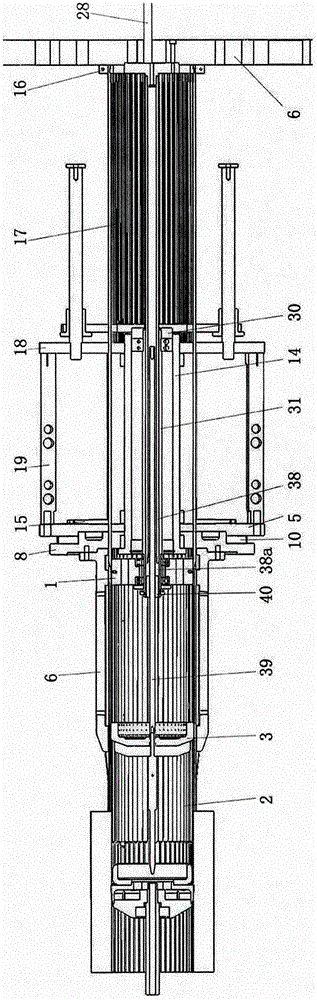

[0028] Such as Figure 1 to Figure 6 As shown, the stator wire embedding device of the present invention includes a guide bar mounting seat 1, several guide bars 2, a push head 3, a bracket 4, a first push rod mechanism, a mounting base, an insulating paper storage device, and a forming insulating paper storage device , the paper pushing mechanism, the first driving mechanism, and the second driving mechanism. The following describes each part and the relationship between them in detail:

[0029] One end of each guide bar is evenly spaced and fixed on the peripheral surface of the guide bar mounting seat to form a non-closed annular space. In this embodiment, the peripheral surface of the guide bar mounting seat 1 is provided with mounting grooves at intervals, and each One end of the guide bar 2 is located in the installation groove and is fixed with the guide bar mounting seat to form a non-closed annular space, and the push head 3 is located in the non-closed annular space....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com