Wire-drawing device height adjustment device of wire-drawing device head of racket wiring device

The technology of a height adjustment device and a stringing machine is applied to rackets, string rackets, sports accessories, etc., and can solve problems such as inability to adjust, racket frame damage, affecting the performance of the net, badminton sports interest, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable your examiners to have a further understanding of the present invention, hereby give the following specific examples for illustration.

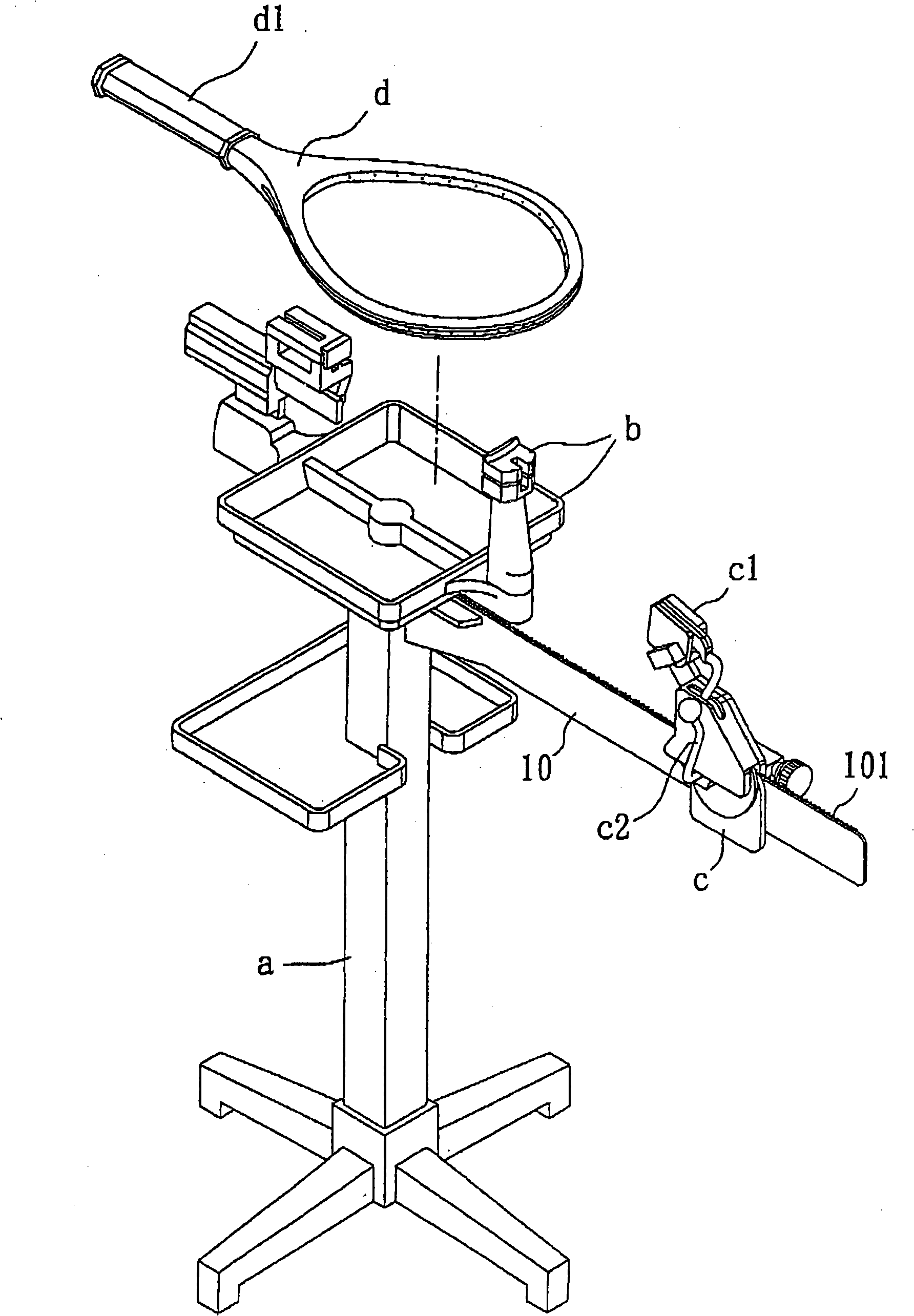

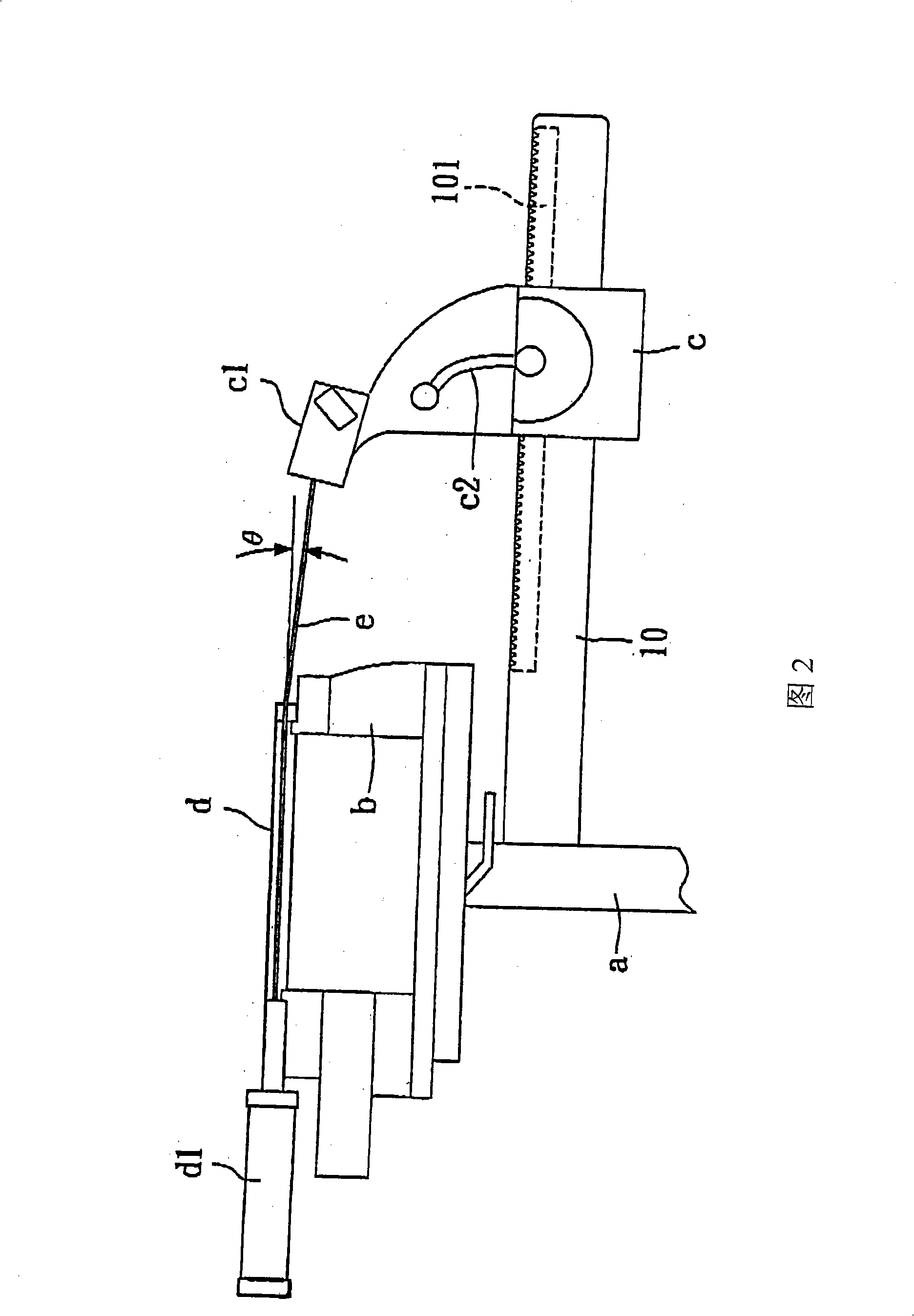

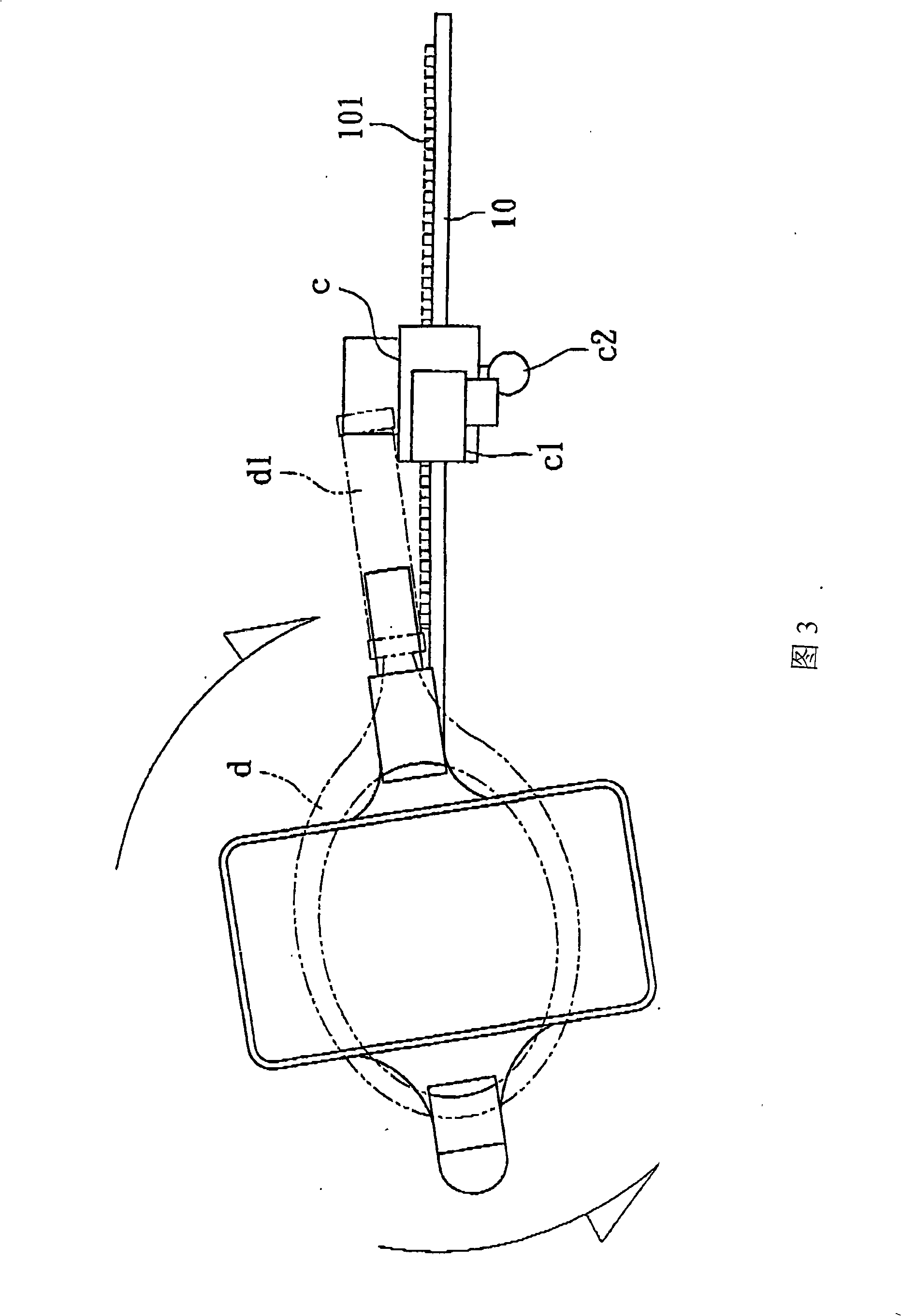

[0041] Dear examiners please refer to Figure 5, the present invention "the height adjustment device of the stringer head of the racket stringing machine" means that the racket stringing machine mainly has a base a, a holding frame b, a stringer head c and A base rod f, the horizontal base rod f has a rack f1, and a gear f2 is meshed on the top of the rack f1, so that the drawing head c combined with the base rod f is meshed with the rack f1 through the gear f2, and according to The rack f1 can be moved, and the wire-drawing machine head c includes at least a wire-drawing device c1 and a wire-drawing rod c2 (see also FIG. 6 ).

[0042] The height adjustment device mainly refers to that the seat body of the terminal head c is divided into an upper seat c3 and a lower seat c4, and the wire puller c1 is combined with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com