A method for denitrification in vd furnace using CO2 steelmaking

A CO2 and denitrification technology, applied in the field of steelmaking technology, can solve the problems of increased smelting costs, unrealized deep denitrification, complicated treatment procedures, etc., and achieve the effects of prolonging the life of the bottom blowing, promoting rapid flotation, and reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention is applied to a 70t ladle VD processing station.

[0032] A VD furnace utilizes CO 2 The method for steelmaking denitrification, its step is as follows:

[0033] 1) The ladle enters the VD station, and the molten steel is subjected to temperature measurement, sampling, and wire feeding. When entering the station, the carbon content is 0.07%, the nitrogen content is 64ppm, and the molten steel temperature is 1627°C;

[0034] 2) VD enters the vacuum stage, the smelting adopts the strong denitrification mode, the bottom blowing of the ladle is turned on, and CO is injected into the ladle 2 -Ar mixed gas, CO 2 The mixing ratio is 60%, and the flow rate of the bottom blowing is controlled to 0.6NL / min·t to ensure the normal operation of the bottom blowing during the vacuuming process, and the vacuum degree is increased to 67Pa after 4 minutes;

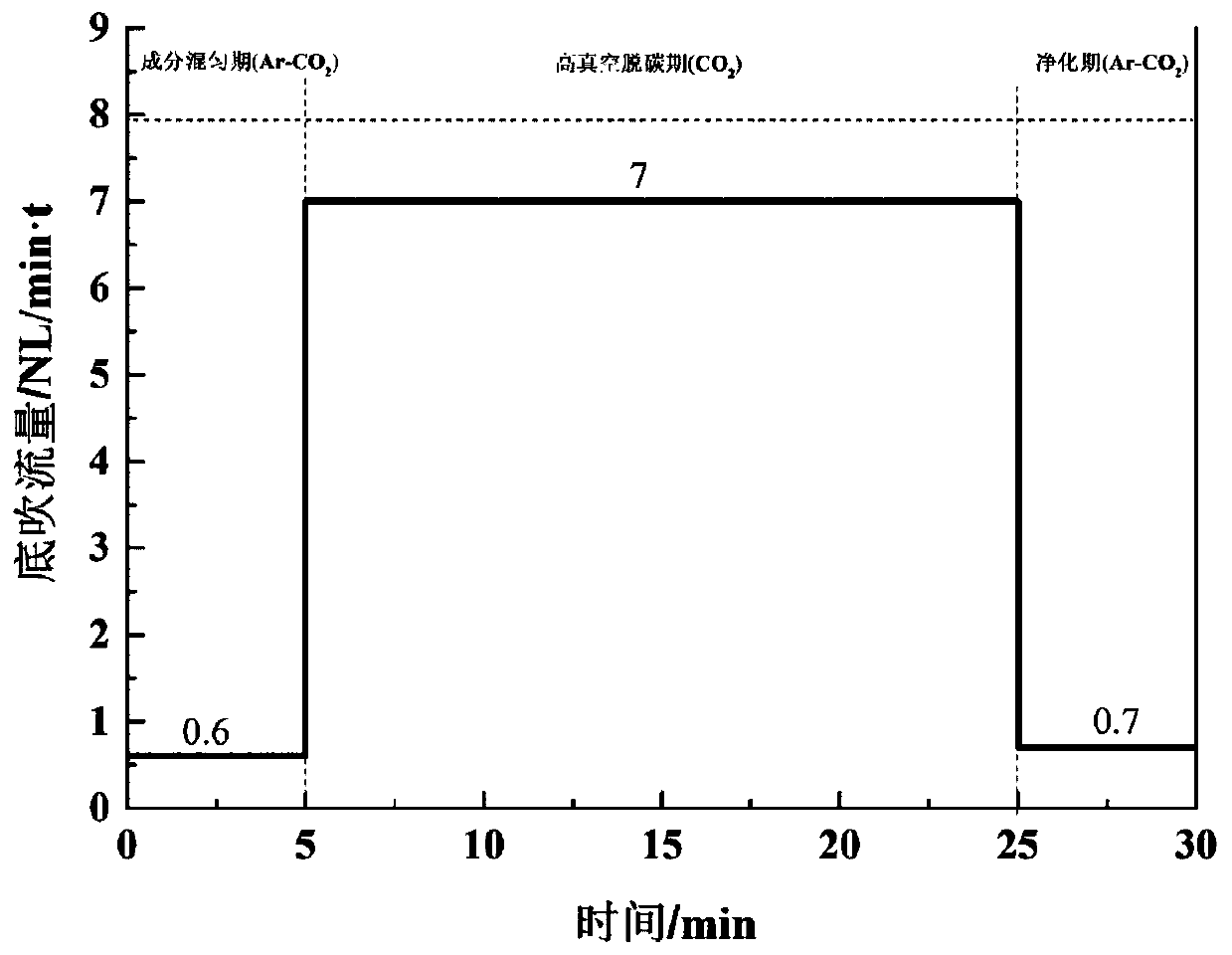

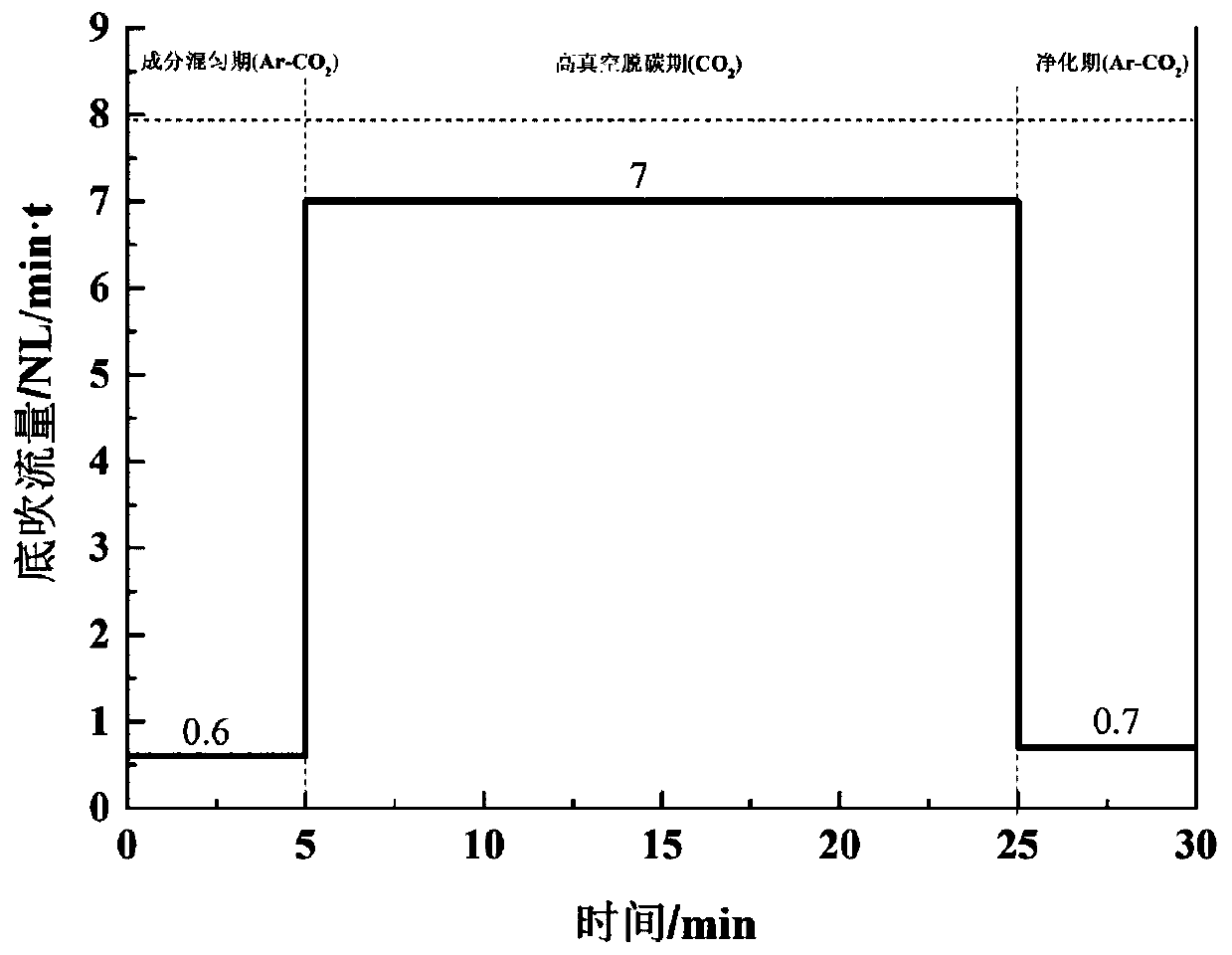

[0035]3) After reaching the vacuum degree, close the bottom blowing Ar gas supply pipeline, adjust the bottom blow...

Embodiment 2

[0042] The invention is applied to a 150t ladle VD processing station.

[0043] A VD furnace utilizes CO 2 The method for steelmaking denitrification, its step is as follows:

[0044] 1) The ladle enters the VD station, and the molten steel is subjected to operations such as temperature measurement, sampling, and wire feeding. The carbon content of the incoming station is 0.04%, the nitrogen content is 49ppm, and the molten steel temperature is 1630°C;

[0045] 2) VD enters the vacuum stage, the smelting adopts the weak denitrification mode, the bottom blowing of the ladle is turned on, and CO is injected into the ladle 2 -Ar mixed gas, CO 2 The mixing ratio is 60%, and the flow rate of the bottom blowing is controlled to 0.6NL / min·t to ensure the normal operation of the bottom blowing during the vacuuming process, and the vacuum degree is increased to 65Pa after 6 minutes;

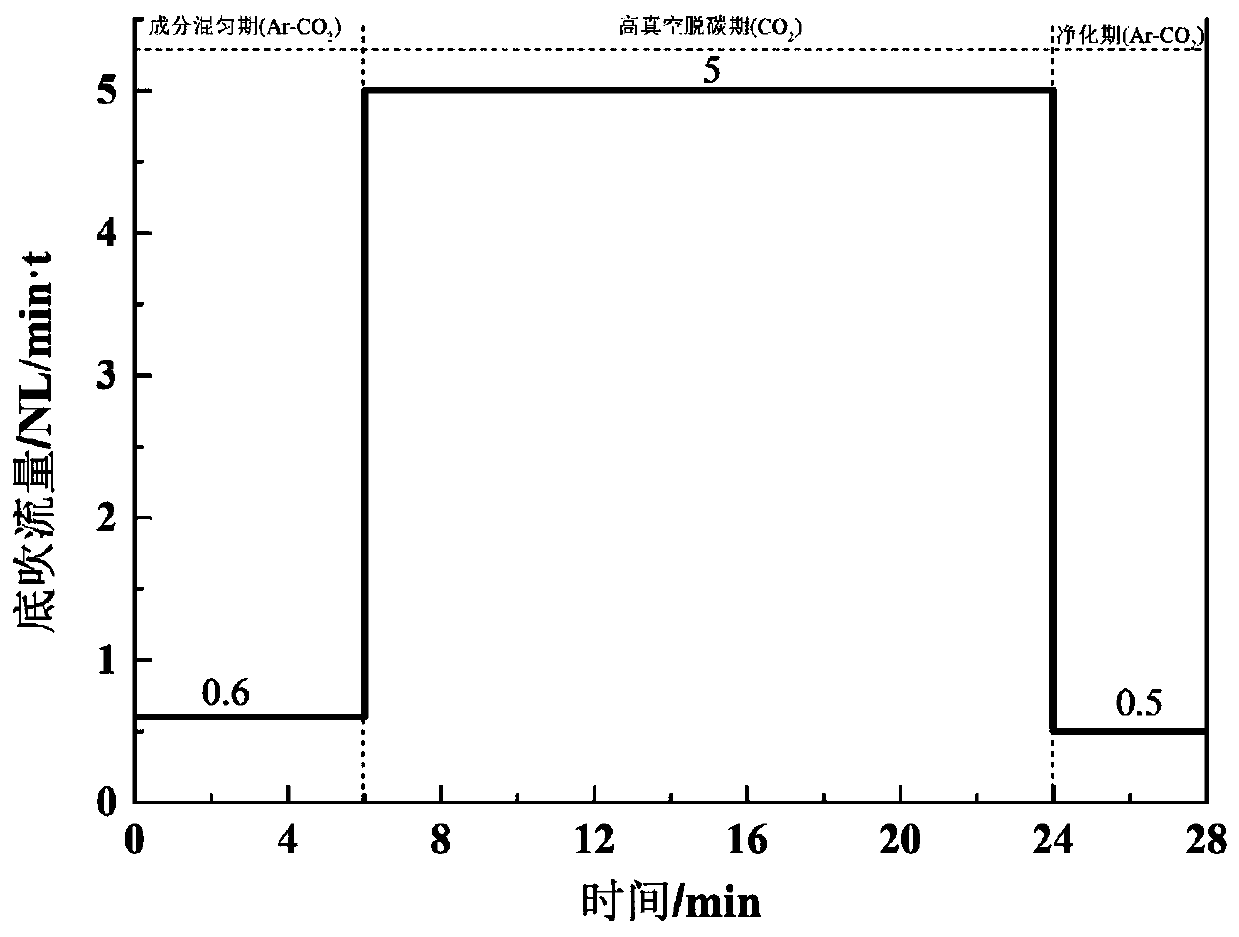

[0046] 3) After reaching the vacuum degree, close the bottom blowing Ar gas supply pipeline, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com