Simple and general automatic negative pressure lamination type vacuum OCA laminating machine

A technology of lamination type and lamination machine, applied in the direction of lamination, application, lamination device, etc., can solve the cost of increasing maintenance and waste of resources, unable to observe the lamination effect in real time, and the lamination effect is not ideal, etc. The problem is to achieve the effect of low production cost, simple structure and good pressing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

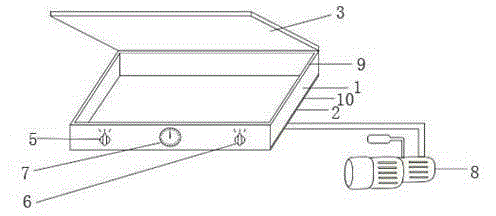

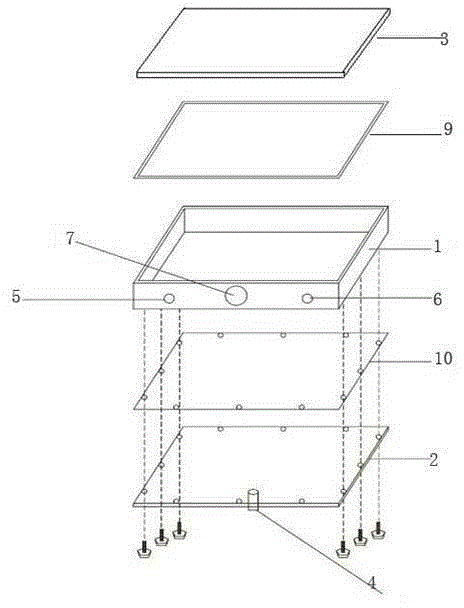

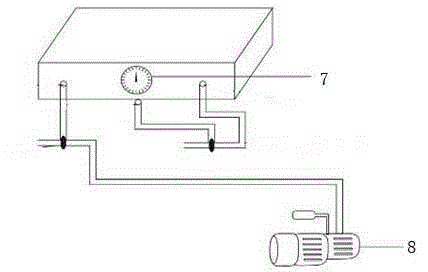

[0019] A simple and universal automatic negative pressure bonding type vacuum OCA laminating machine, which is provided with a frame body 1, a bottom plate 2 on the lower part of the frame body 1, a transparent cover plate 3 on the upper part of the frame body 1, and an equal pressure hole on the bottom plate 2 4. There is a frame between the base plate 2 and the transparent cover plate 3. The frame 1 is provided with an air extraction valve 5 and a pressing valve 6. A vacuum gauge 7 is arranged between the air extraction valve 5 and the pressing valve 6. A vacuum machine 8 is connected next to the valve 5, an upper sealing rubber ring 9 and a lower sealing pressing rubber 10 are arranged on the frame body 1, a transparent cover plate 3, an upper sealing rubber ring 9, a frame body 1, a lower sealing pressing rubber 10, The base plates 2 are jointly combined into a clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com