Frozen liquefied gas tank container vacuum-pumping system and method

A vacuum system, freezing and liquefaction technology, applied in the field of vacuum system, can solve the problems of unfavorable moisture and other gas precipitation, slow power consumption, slow internal circulation heating, etc., to achieve rapid heating of the interlayer space, increase the vacuuming speed, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

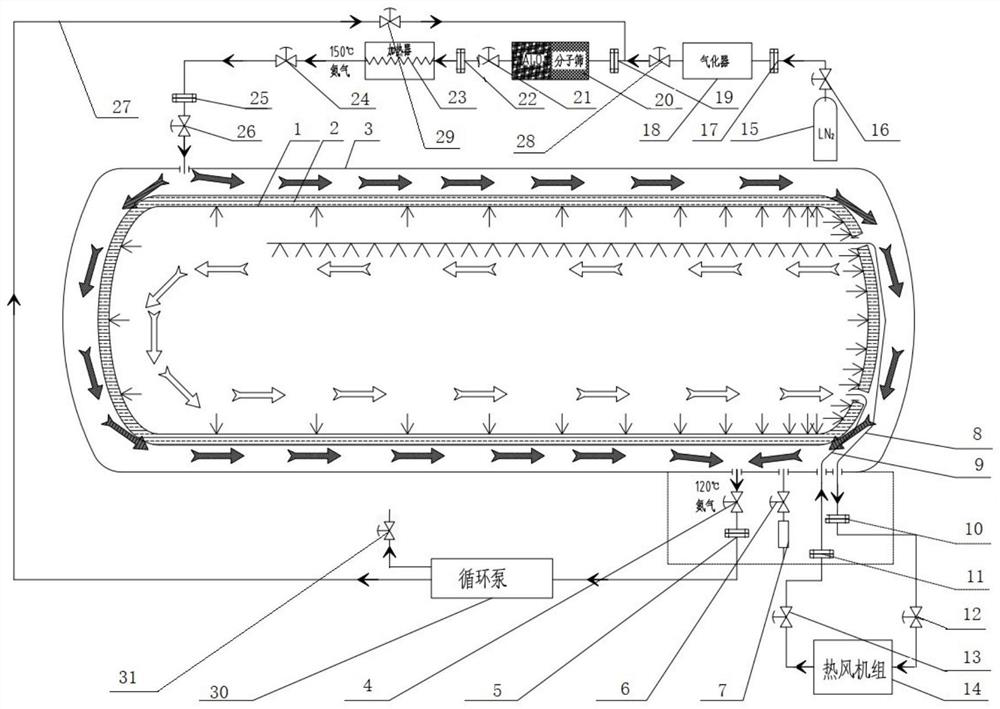

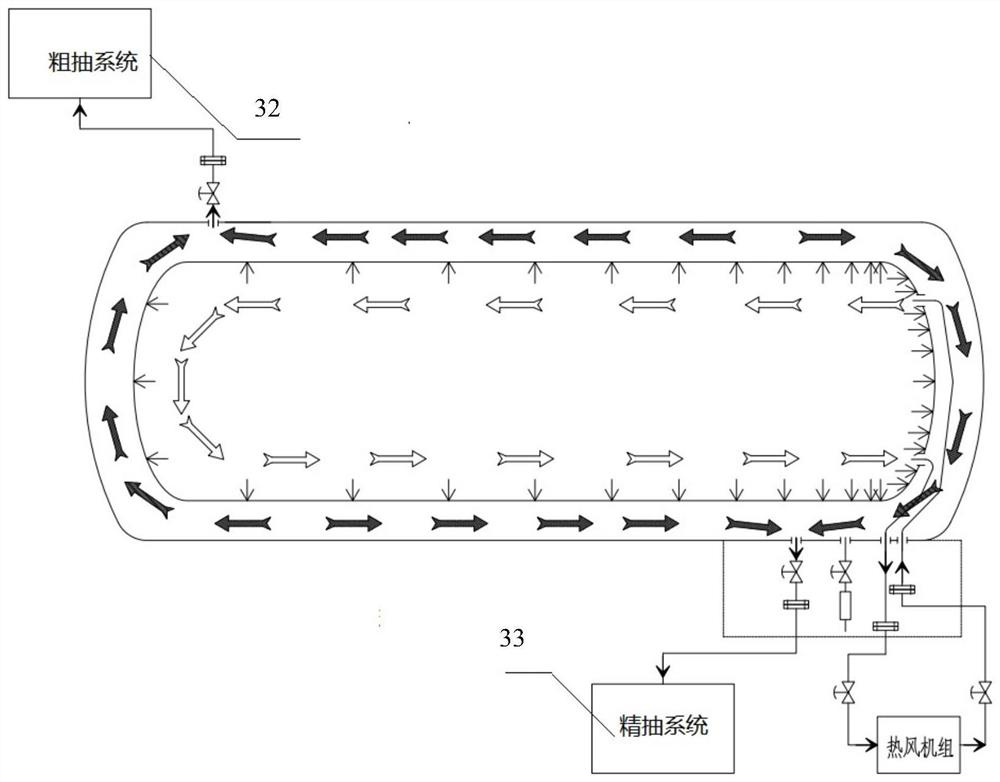

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are only for illustration, and are not intended to limit the present application.

[0038] The vacuum pumping system for refrigerated liquefied gas tank containers of the present invention comprises an inner cylinder body 1 and an outer cylinder body 3 with a heat insulating layer 2 between the inner cylinder body and the outer cylinder body; the inner cylinder body 1 and the outer cylinder body 3 Through the helium leak detection test, it is ensured that the leak rate meets the standard requirements; the heat insulation layer 2 is made of aluminum foil and heat insulation paper at intervals, and air holes are provided in its thickness direction.

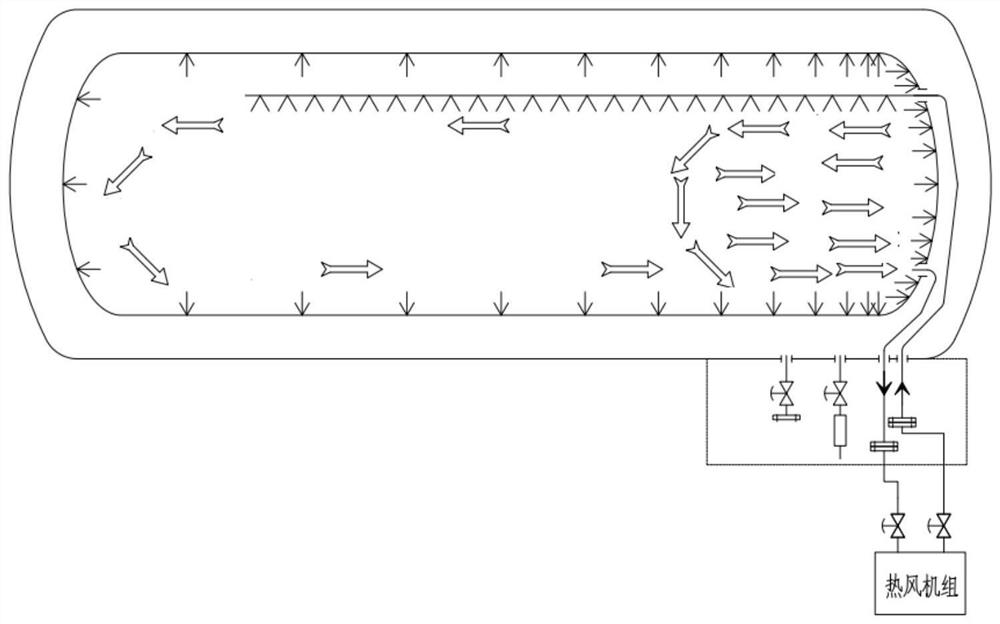

[0039] The tank heating module includes a hot air circulation unit 14, the hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com