Spray atomization system for vacuum oil purifier

A vacuum oil purifier and atomization system technology, which is applied in the field of spray atomization system, can solve the problems of reducing the oil purification efficiency of the vacuum oil purifier, poor atomization effect, poor purification effect, etc., and can increase the oil film formation area , improve the quality of purification, speed up the effect of water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

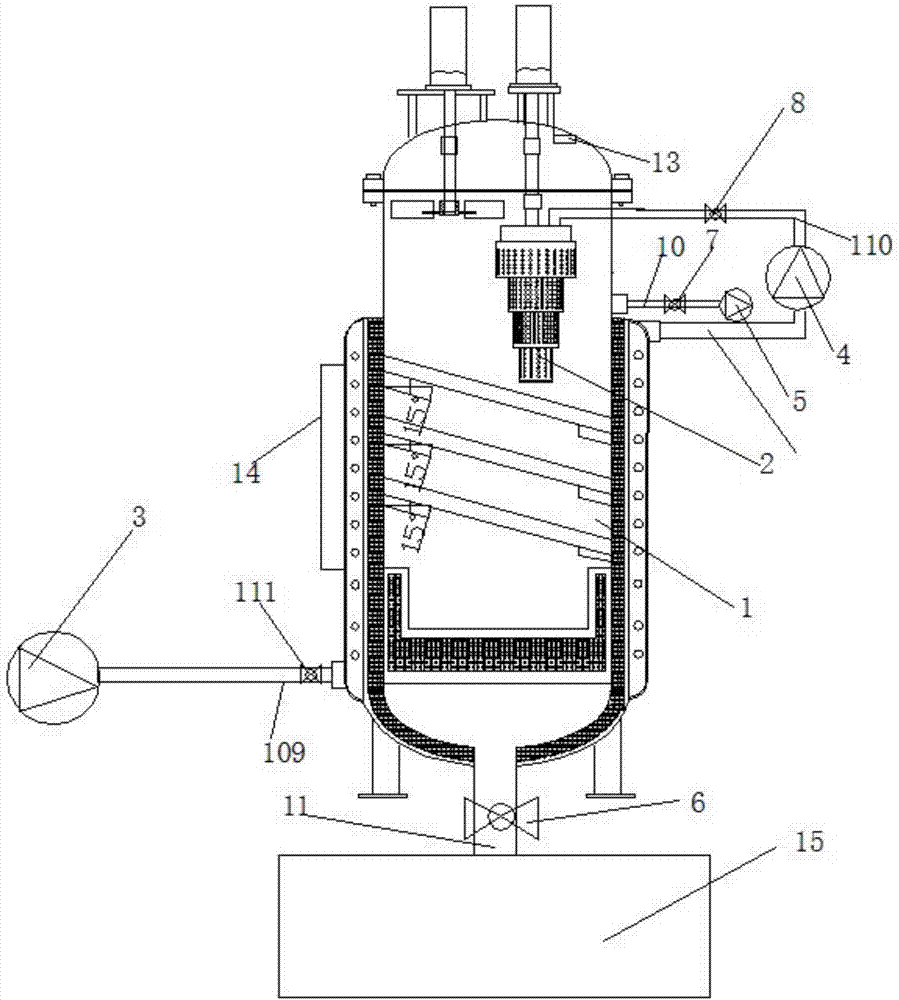

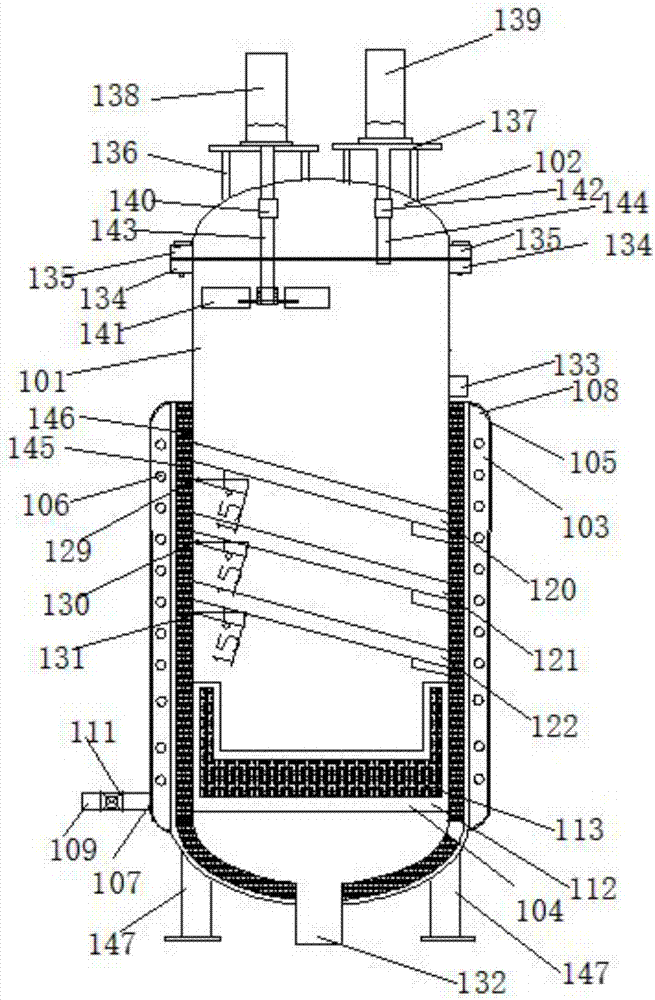

[0040] As shown in the figure, a spray atomization system for a vacuum oil purifier includes a vacuum tank, a spray device, a crude oil tank, a first oil pump, a second oil pump, a PLC controller, an external liquid level gauge, a pressure sensor.

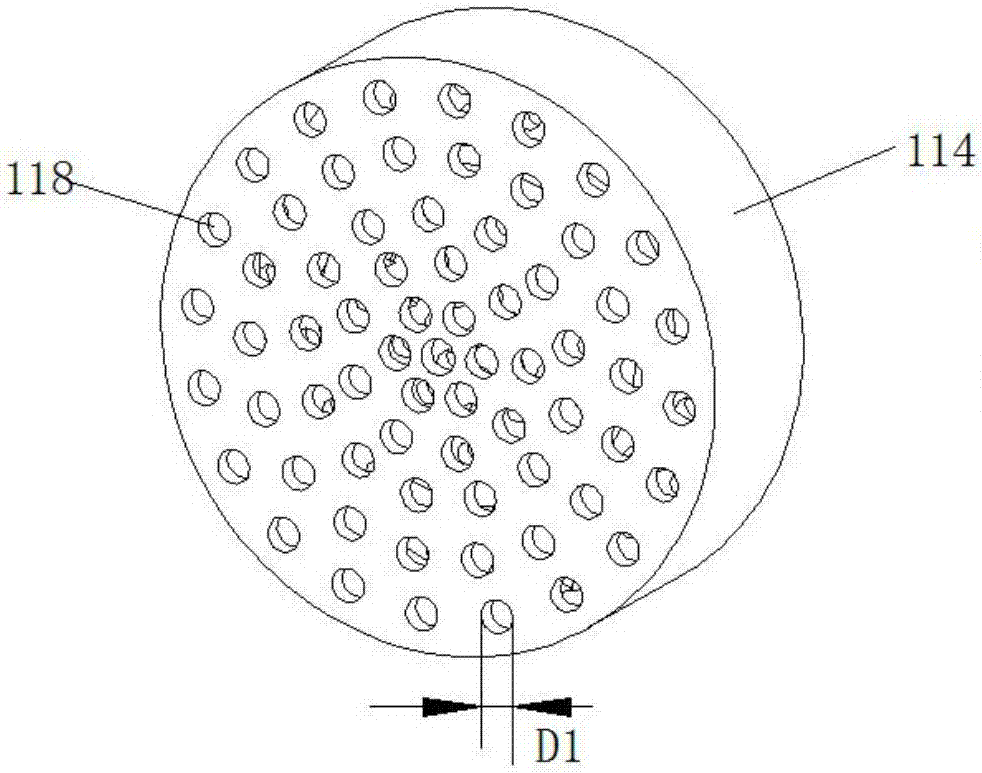

[0041] Vacuum tank, including tank body, tank cover, fan, heating device, adsorption purification device, first mesh plate, second mesh plate, third mesh plate, rock wool protective layer, stainless steel protective layer; the heating device includes heating Cover, disk-shaped heating tube, feed inlet, and discharge port. The inside of the heating jacket is a cavity structure. The disk-shaped heating pipe is fixed inside the heating jacket. There is a discharge port on the top, and the discharge pipe is connected to the discharge port; the adsorption and purification device includes a purification bottle and an adsorbent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com