Electrolytic tank cover for preventing and controlling acid mist

An electrolytic cell and acid mist technology, applied in the electrolytic process, electrolytic components and other directions, can solve the problems of low automation level promotion and application, large surface area of the arc top tank cover structure, frequent movement of the arc top tank cover, etc. Reduce the level of automation requirements, facilitate manual lifting and unloading, and inhibit the effect of acid mist escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

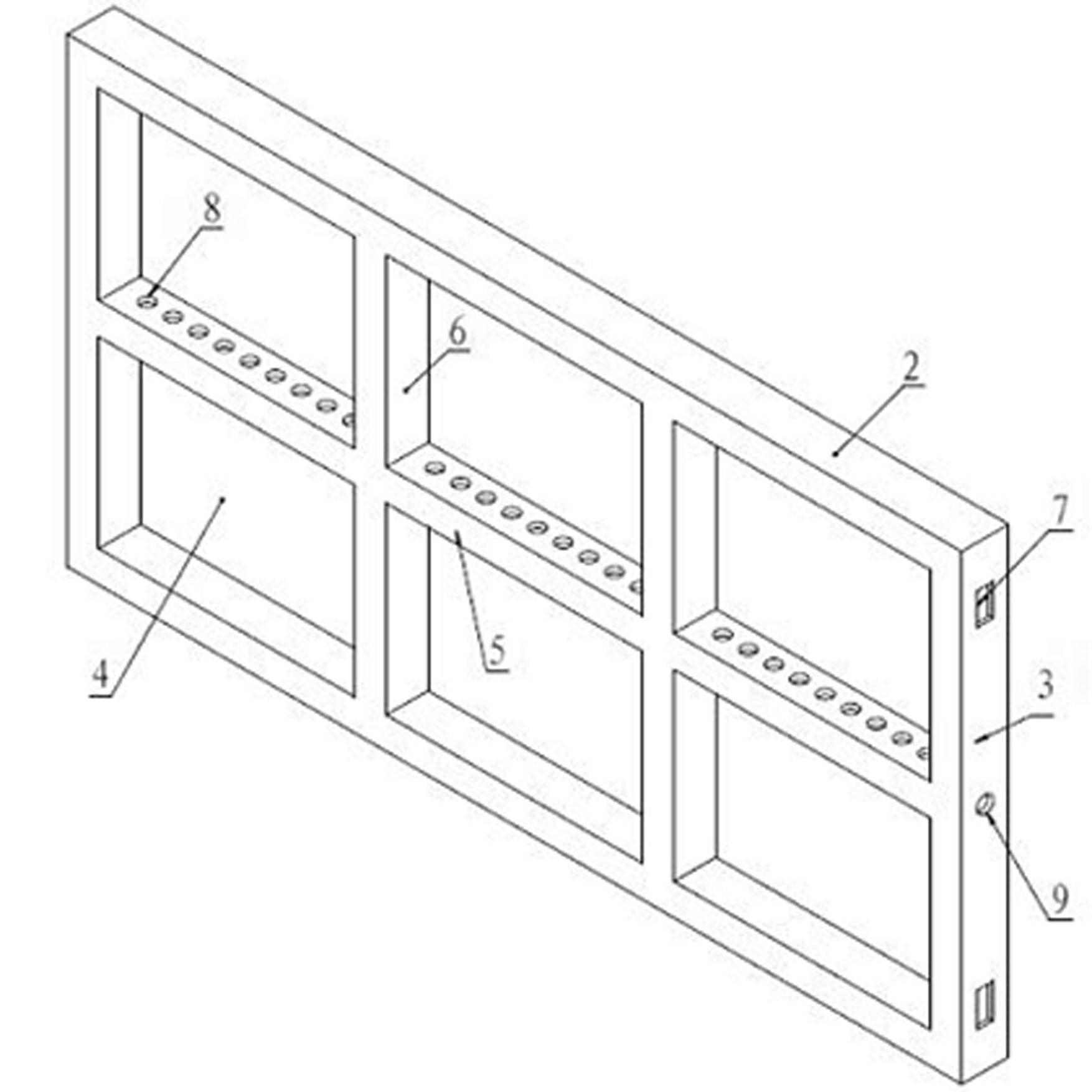

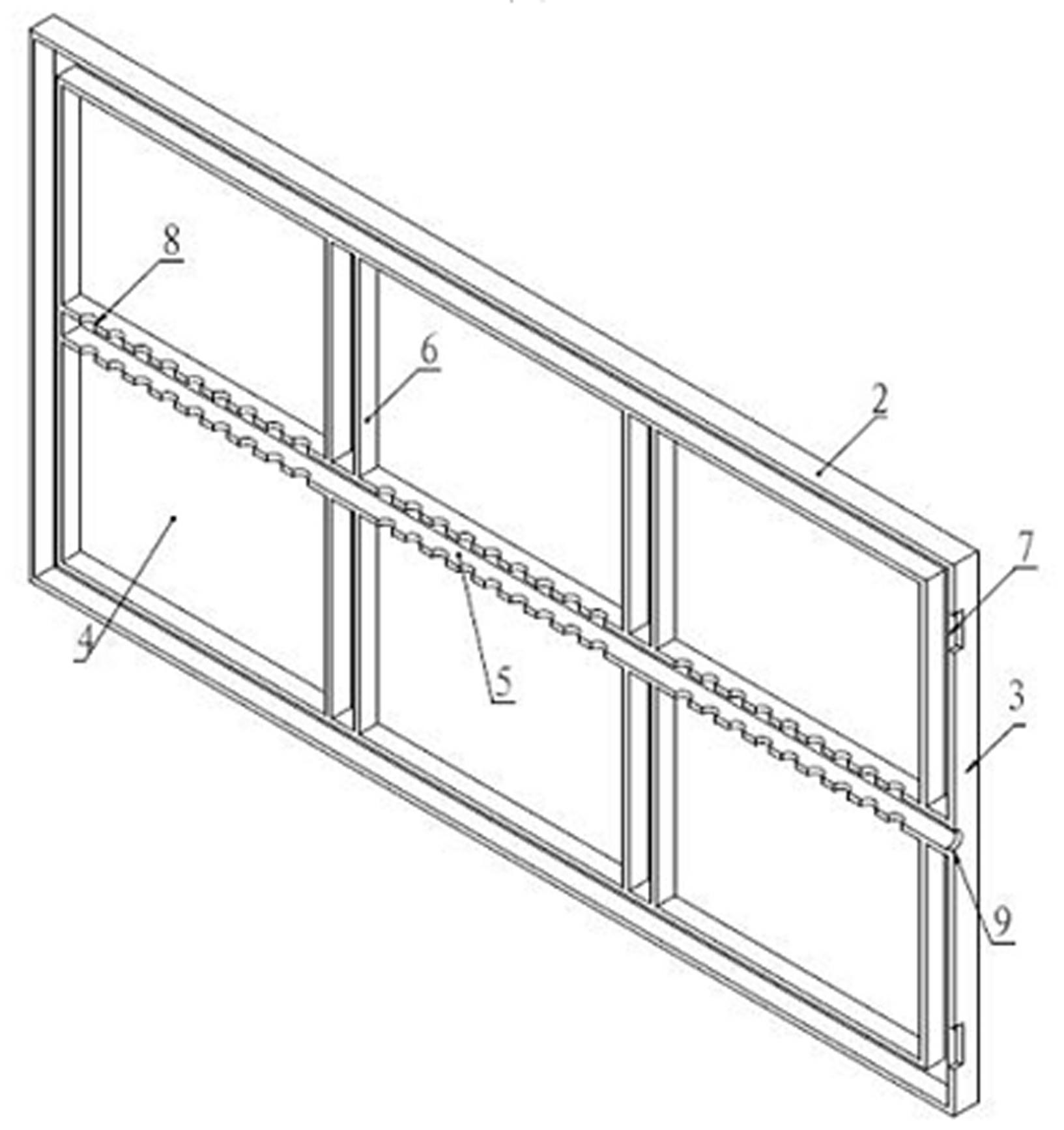

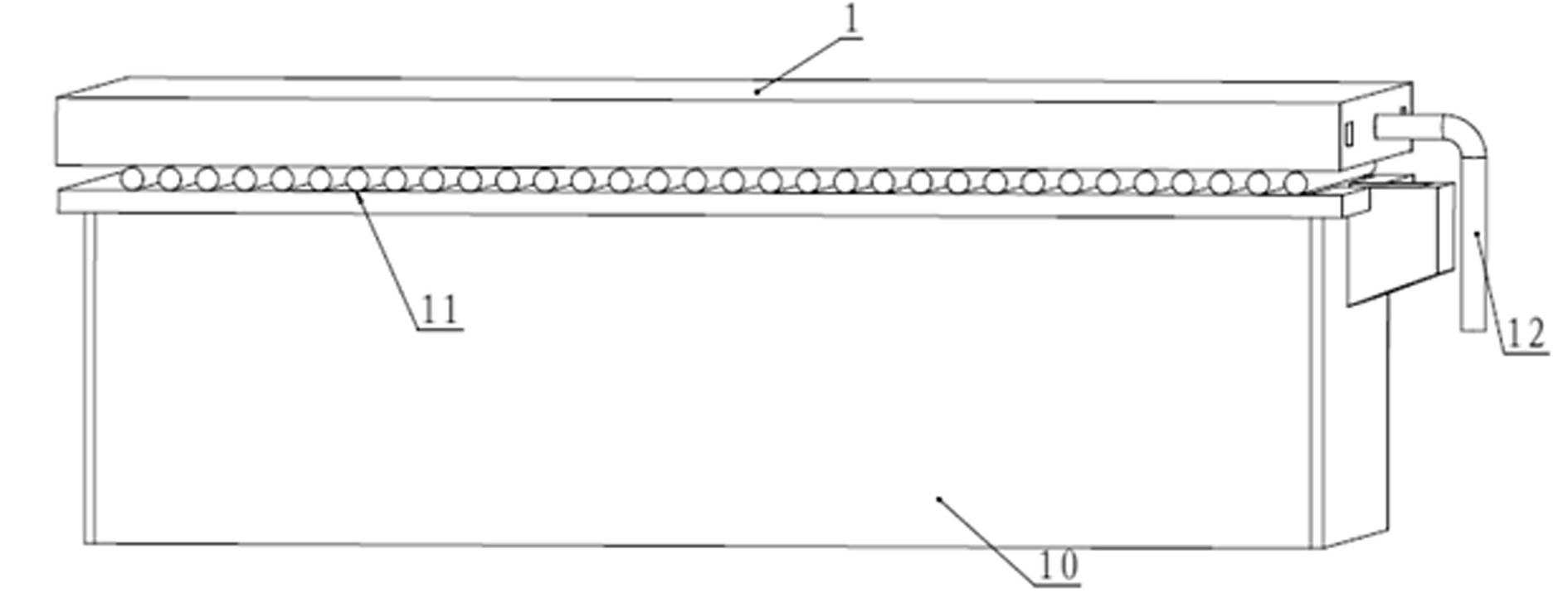

[0021] as attached figure 1 , 2 , shown in 3, a kind of electrolyzer cover of preventing and controlling acid mist, described electrolyzer cover is cuboid 1, and it has long and short side wall 2,3 and top plate 4, and the inner surface of described cuboid 1 is provided with a mesh Supporting structure; the mesh support structure includes an air exhaust branch pipe 5 arranged along the longitudinal centerline of the cuboid 1 and reinforcing ribs 6 arranged at equal intervals on both sides of the air exhaust branch pipe 5; There is an exhaust hole 8; the short side wall 3 of the cuboid 1 has a hole 9, and the hole 9 communicates with the exhaust branch pipe 5, and the external exhaust duct 12 forms a passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com