A baffle and a vacuum dryer comprising the baffle

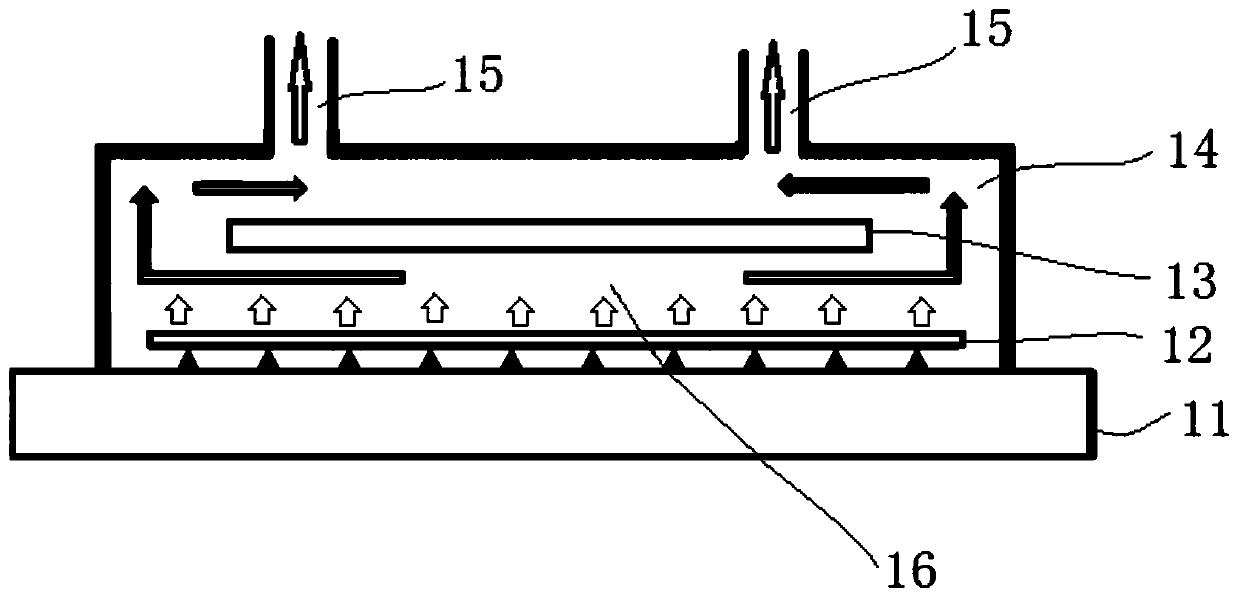

A baffle and panel technology, which is applied in the field of liquid crystal display panel manufacturing, can solve the problems of poor air extraction at the center and uneven air extraction of the array substrate, and achieve the effects of uniform air extraction, avoiding poor air extraction and uniform airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

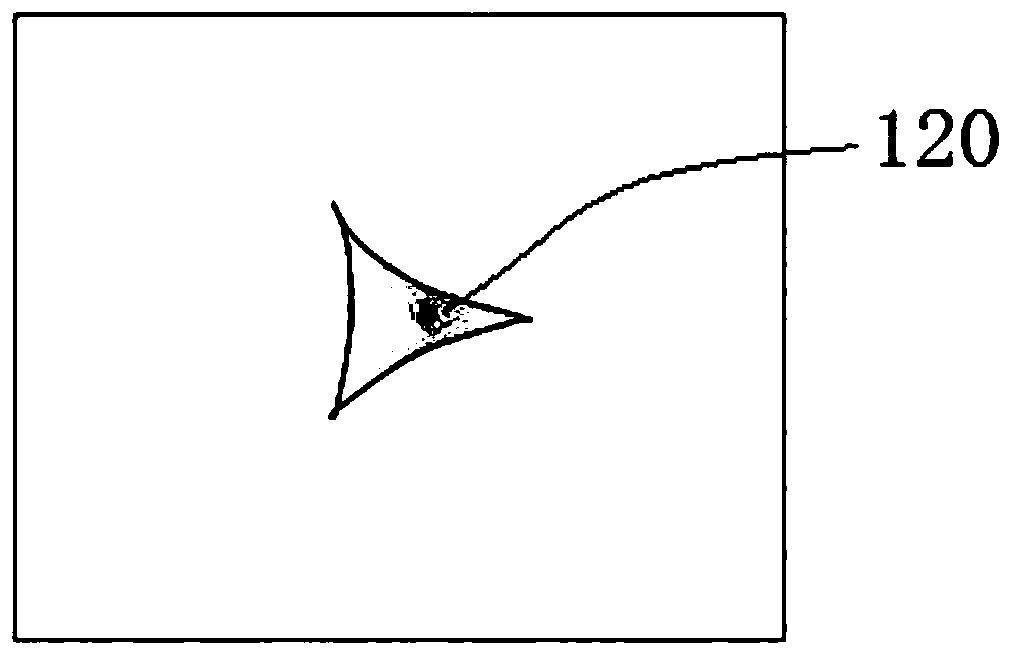

[0032] Such as Figure 5 Is a schematic diagram of the first baffle 23 proposed by the present invention, Image 6 for Figure 5 A-A section view, combined Figure 5 with Image 6 The baffle 23 includes a first plate surface 233 and a second plate surface 234. The first plate surface 233 and the second plate surface 234 are arranged relatively parallel, and the first plate surface 233 and the second plate surface 234 are respectively arranged on the baffle plate 23. Viewed along the normal direction of the first plate surface, the central area of the baffle 23 has a hole 232 passing through the first plate surface 233 and the second plate surface 234, such as Figure 5 As shown, the hole 232 passes through the first panel surface 233 and the second panel 234, wherein the size of the hole 232 can be adjusted according to actual conditions.

[0033] When the hole 232 is provided at the center of the baffle 23, the volatilized gas in the central area of the array substrate can dir...

Embodiment 2

[0038] In the second embodiment of the present invention, different from the first embodiment, the cross-sectional view of the baffle 23' along A-A is as Figure 7 As shown, the cross section of the peripheral surface 2321' of the hole 232' of the baffle 23' gradually decreases from the second plate surface 234' to the first plate surface 233' along the normal direction of the first plate surface. The angle β between the surface 2321' and the first plate surface 233' is 30 degrees. At the same time, the peripheral surface 237' of the baffle 23' is no longer perpendicular to the first plate surface 233', but the outer peripheral surface of the baffle 23' 237' gradually increases from the second board surface to the first board surface along the normal direction of the first board surface, such as Figure 7 As shown, preferably, the included angle θ between the circumferential surface 237' of the baffle 23' and the first plate surface 233' is 30 degrees.

[0039] When the circumfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com