Vertical-type spraying chamber system

A spray booth and vertical technology, applied in spray booths, spray devices, etc., can solve the problems of air turbidity in spray booths, affecting the working environment, secondary pollution of workpieces, etc., to avoid floating around, good recovery effect, and reduce deposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

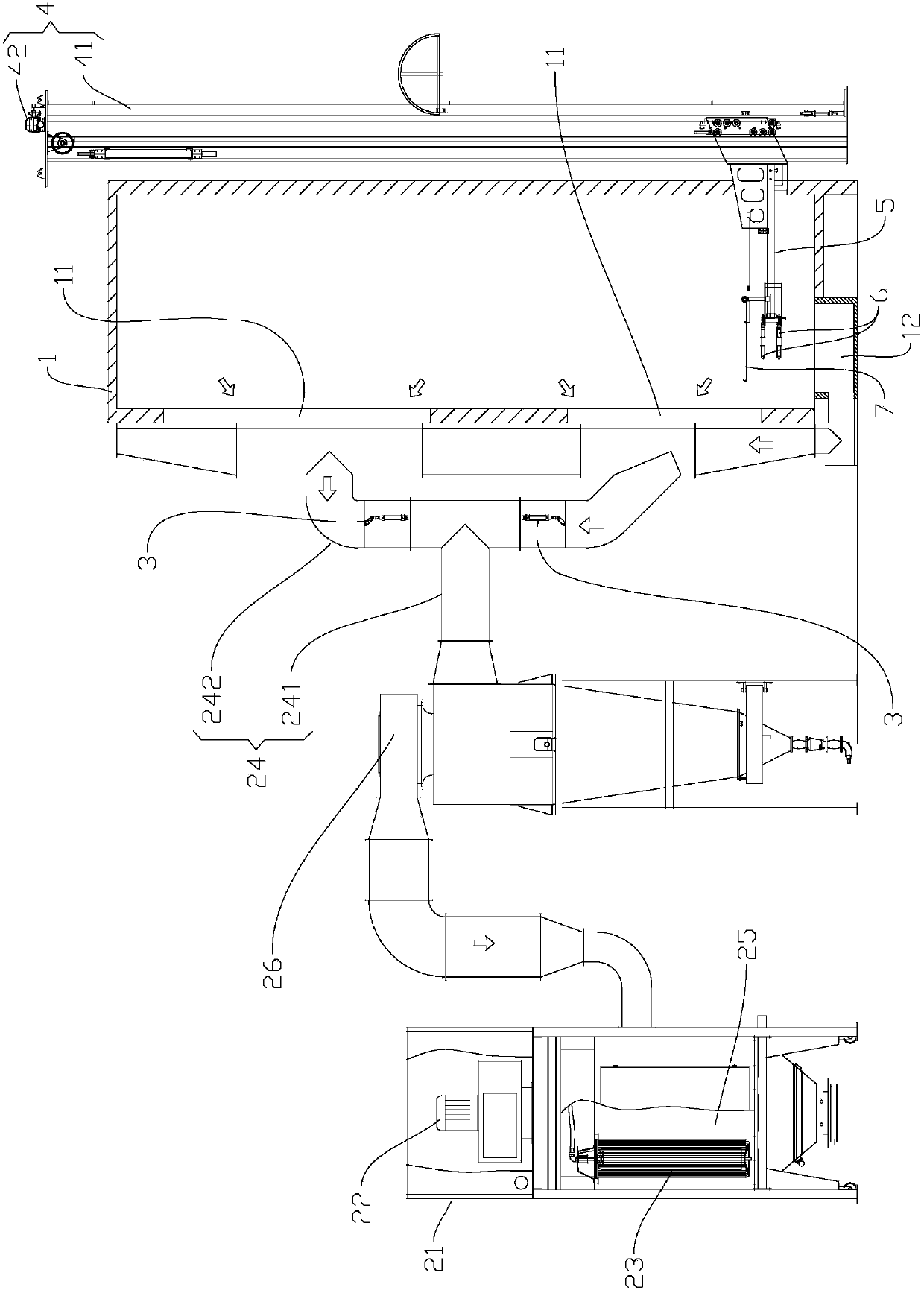

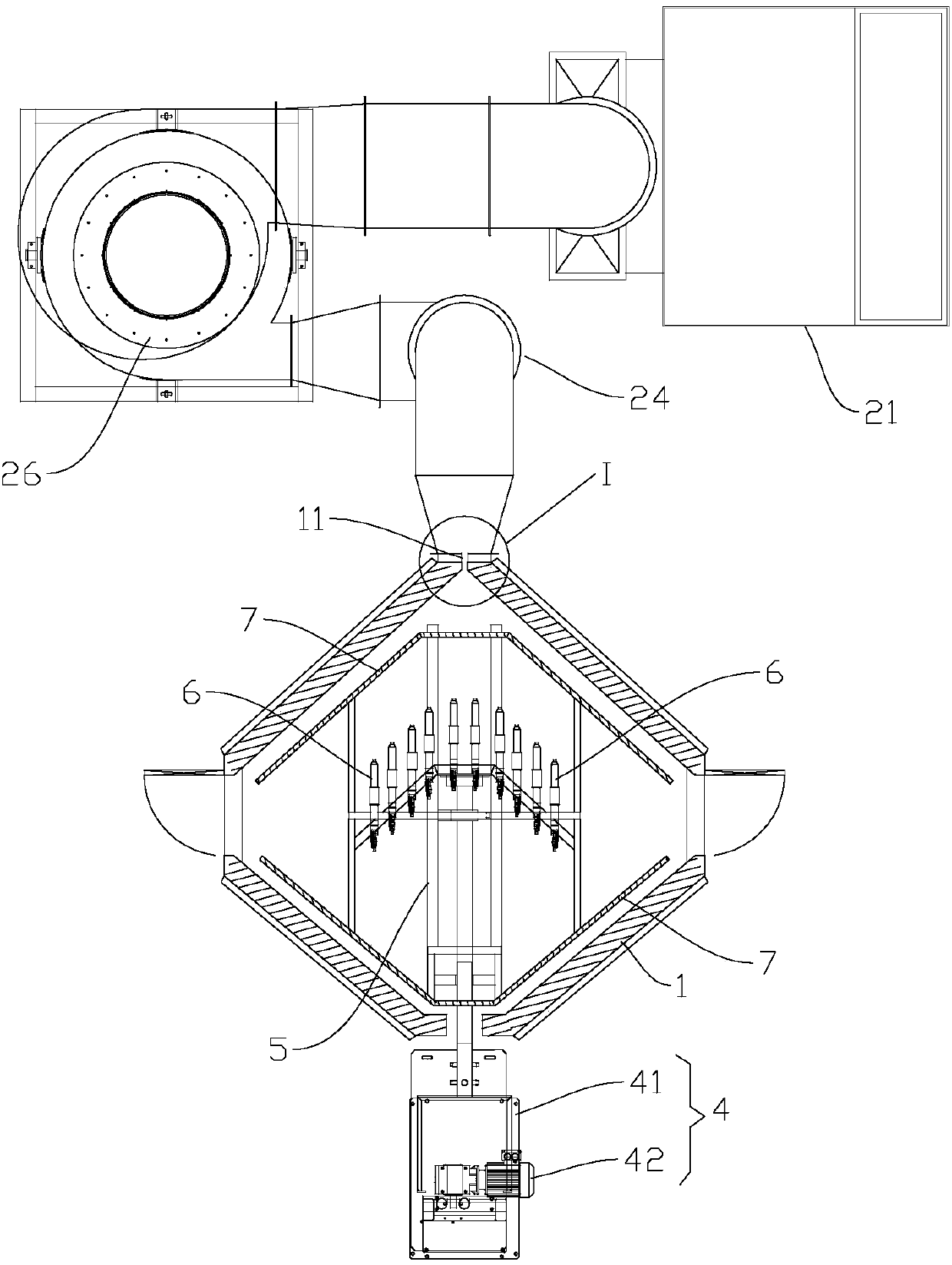

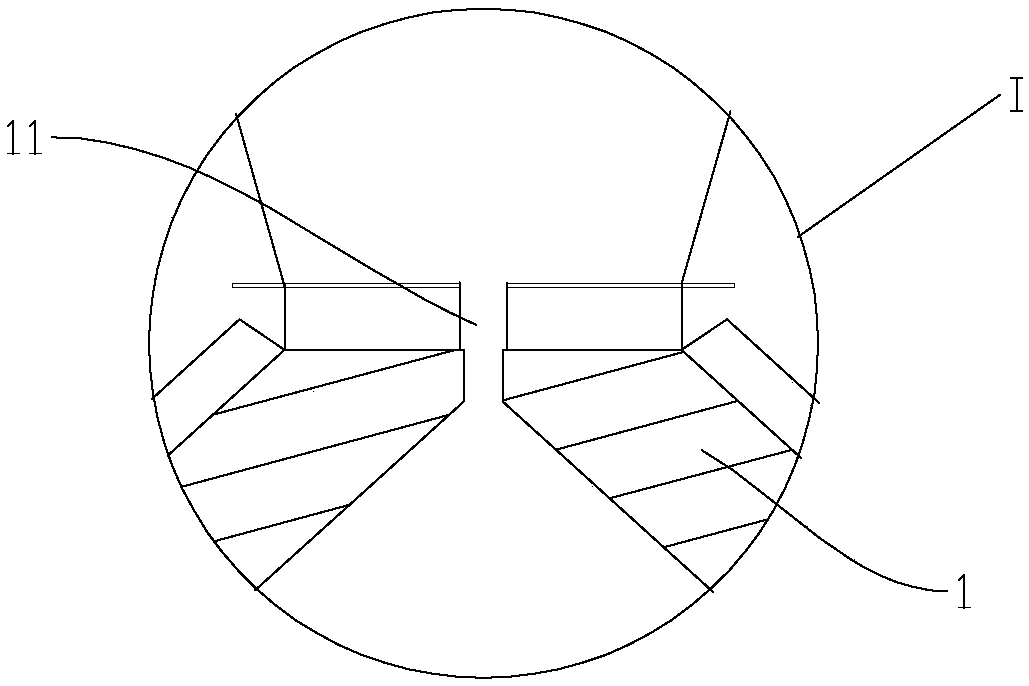

[0019] refer to Figure 1 ~ Figure 3 , the present invention is a vertical spray booth system, including a spray booth 1 and a filter system, the filter system is connected with the spray booth 1 and can take away the air in the spray booth 1. In the present invention, an air suction port 11 is provided on the side wall of the spray booth 1, and the filter system communicates with the air suction port 11. Through this structure, the side suction method is adopted instead of the bottom suction method, and the suction in the whole spray booth 1 is relatively uniform, which effectively prevents the powder from floating around, the powder recovery effect is better, and the environment in the spray booth 1 is optimized. , It reduces the deposition of powder and makes the spray booth 1 easy to clean.

[0020] Preferably, the air suction port 11 is arranged longitudinally on the side wall of the spray booth 1 to make the air extraction in the entire spray booth 1 more uniform.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com