Corn peeling device

A dehulling device and corn technology, applied in food science and other directions, can solve the problems of corn wear, waste, affecting appearance, etc., and achieve the effect of reducing process and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

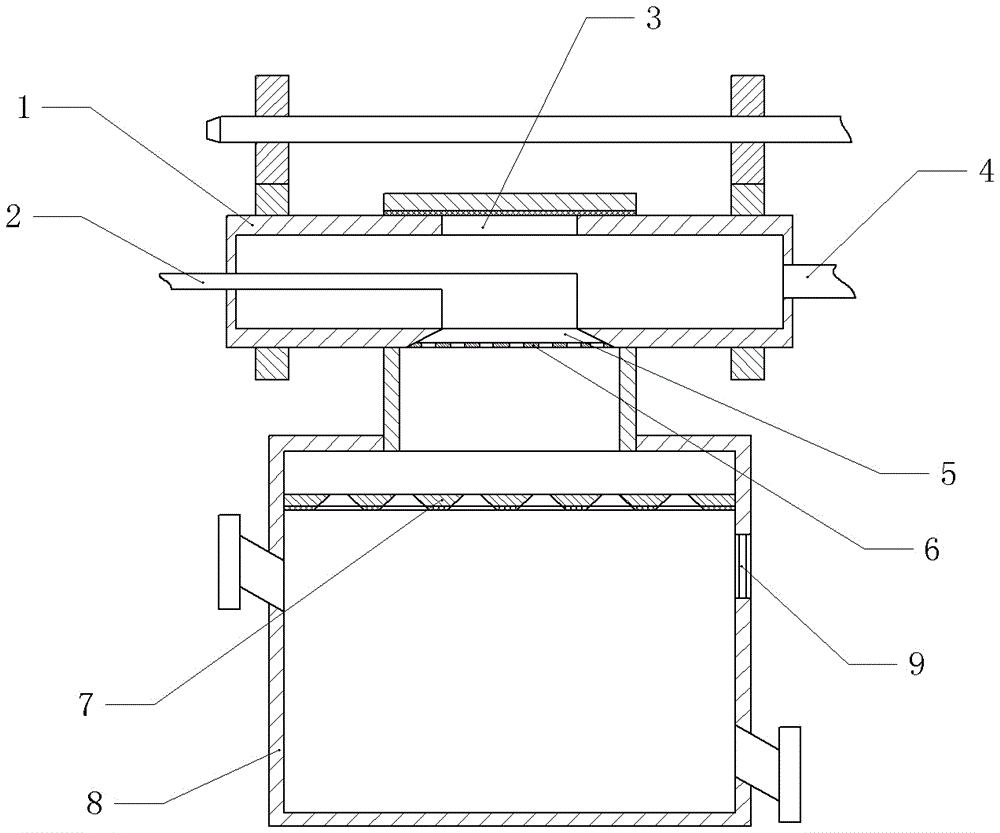

[0025] The reference signs in the accompanying drawings of the description include: drum 1, air extraction pipe 2, air filling port 3, air filling pipe 4, air extraction port 5, screen 6, block 7, peeling box 8, glass window 9.

[0026] Such as figure 1 Shown, a kind of corn peeling device comprises peeling box 8, and the side wall of peeling box 8 is provided with glass window 9, feeding opening, discharging opening, and feeding opening, discharging opening place are all provided with sealing plug, peeling box 8 The upper end is provided with a vertical ventilation pipe, the upper end of the ventilation pipe is sealed, and the upper end of the ventilation pipe is an arc surface, and the inner side of the arc surface is provided with a rubber sealing gasket. There is a horizontal roller 1 inside the ventilation pipe, the two ends of the roller 1 are sealed, and the rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com