Novel dried persimmon forming and processing automation equipment, processing method and novel dried persimmons

An automatic equipment and forming processing technology, which is applied in food processing, food forming, climate change adaptation, etc., can solve the problems of oblate dried persimmons, such as no, unfavorable digestion, and large volume, so as to improve labor productivity, realize quality, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

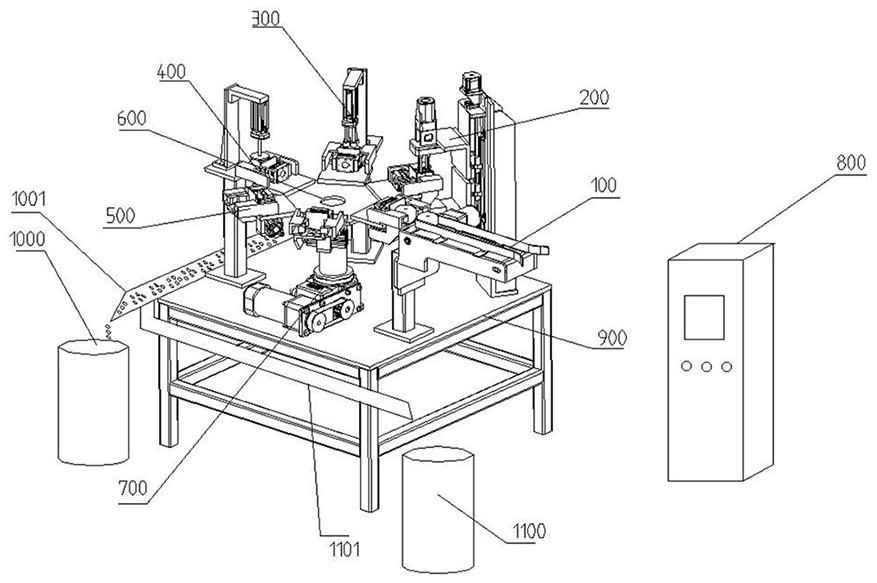

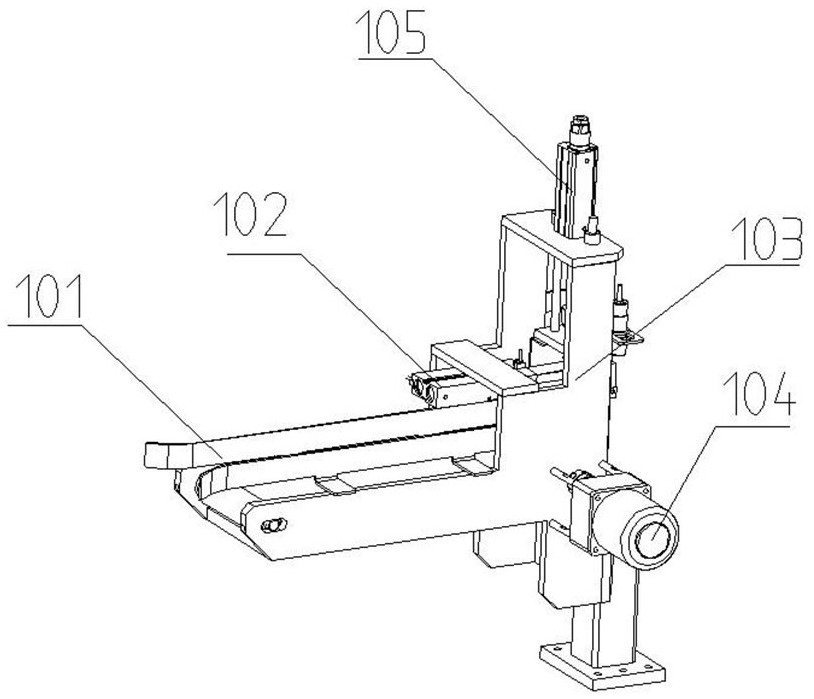

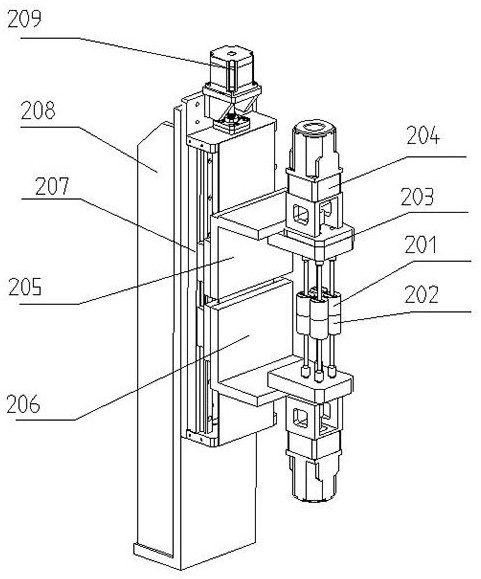

[0036] like Figure 1-Figure 7 As shown, a persimmon forming and processing automation equipment provided by the present invention includes a feeding mechanism 100, a punching mechanism 200, a material distribution mechanism 300, a material cleaning mechanism 400, a charging mechanism 500, a worktable 600, a rotating mechanism 700, an electric Control system 800 and rack 900, feeding mechanism 100 is a mechanism for conveying persimmons into charging mechanism 500, punching mechanism 200 is used for processing the whole persimmon into n small persimmons (n≥2, take a natural number), divided into The feeding mechanism 300 completely separates the n small persimmons processed by the punching mechanism 200, and finally transports the small persimmons to the finished product collector 1000. The residual material is collected into the residual material coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com