An automatic juicer for fresh oranges

A juicer and automatic technology, applied in the field of orange juicer and juicer, can solve the problems of slow pressing speed, troublesome pressing process, low degree of automation, etc., to achieve convenient operation, improve juice extraction efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

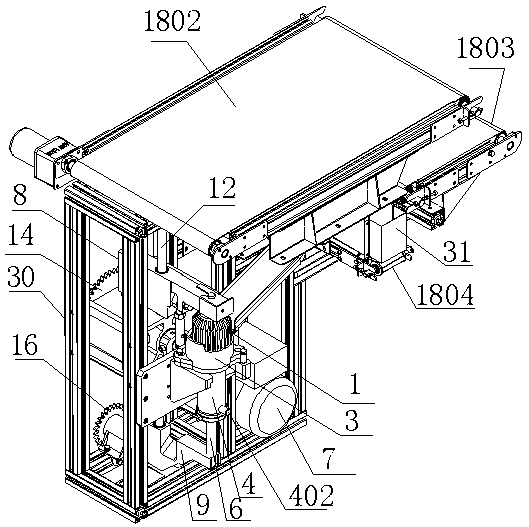

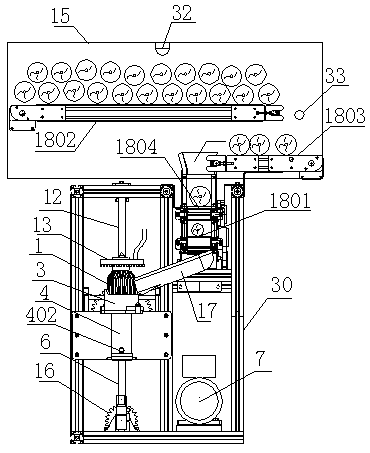

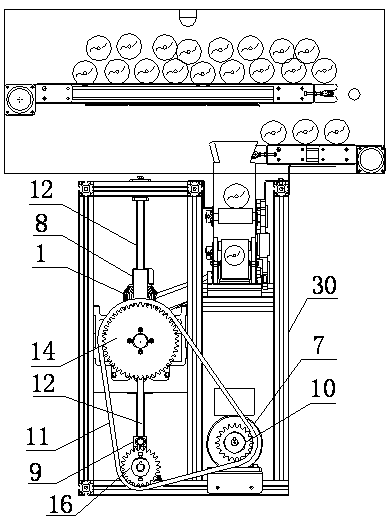

[0041] like figure 1 , 2 , 3, 4, and 5, an automatic juice extractor for fresh oranges mainly includes a squeezing mechanism, a driving mechanism and a feeding mechanism arranged on the frame 30. The frame is made of frame aluminum profile.

[0042] The pressing mechanism includes an opposing upper pressing cup 1 and a lower pressing cup 2. The upper pressing cup 1 and the lower pressing cup 2 have cup claws that are engaged with each other, that is, the cup wall is composed of cup claws arranged at intervals. The cup claws of the cup 1 and the pressing cup 2 can be inserted into each other's claw gaps, so that when the pressing cup 1 and the pressing cup 2 move relative to each other, the space between the two cups gradually shrinks. In order to prevent part of the juice from leaking out, the pressing cup 2 has a shell 3, and a liquid collecting barrel 4 for collecting juice is arranged under the pressing cup 2, and the liquid inlet 401 of the liquid collecting barrel 4 is ...

Embodiment 2

[0048] like Figure 11 As shown, different from Embodiment 1, the juice extractor is also provided with a cleaning mechanism, that is, a sleeve 20 is fixed at the bottom of the pressing cup 1, and the lower port of the sleeve 20 communicates with the bottom of the cup, and the sleeve 20 A telescopic tube 21 that can slide relative to the casing 20 is inserted, and the lower port of the casing 20 is provided with a circular plug 22 that closes the port. The radius of the plug 22 is larger than the radius of the lower port of the casing 20, so that the upward movement of the plug 22 can Block the lower port of the casing 20, the wall of the casing 20 at the plug 22 is provided with a spray hole 214, and the casing 20 is connected with an air inlet or water inlet hose 23, and the inlet hose and the water inlet can also be connected at the same time. A control mechanism that controls the relative movement of the sleeve 20 and the sleeve 20, such as a pneumatic cylinder or a rack a...

Embodiment 3

[0054] like Figure 15 As shown, the difference from Embodiments 1 and 2 is that, as a preference, in the above-mentioned automatic juice extractor for fresh oranges, the filter tube 5 has a section of extension pipe extending from the bottom of the liquid collection barrel 4, and the extension pipe There is a slag discharge hole 501 on the pipe wall of the body, and the top of the pressing rod 6 has a chamfered slope 602 facing the direction of the slag discharge hole. The residue at the slag discharge hole in the pipe body is pushed out from the slag discharge hole when the push rod 6 moves upward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com