Forming mould of thermal-insulation layer of thermal-insulation pipeline

A technology for forming molds and thermal insulation layers, which is applied to the field of forming molds for thermal insulation layers of thermal insulation pipes, can solve problems such as damage to thermal insulation layers and uneven surface thickness of thermal insulation layers, and achieve the effects of improving adsorption force and uniform surface thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

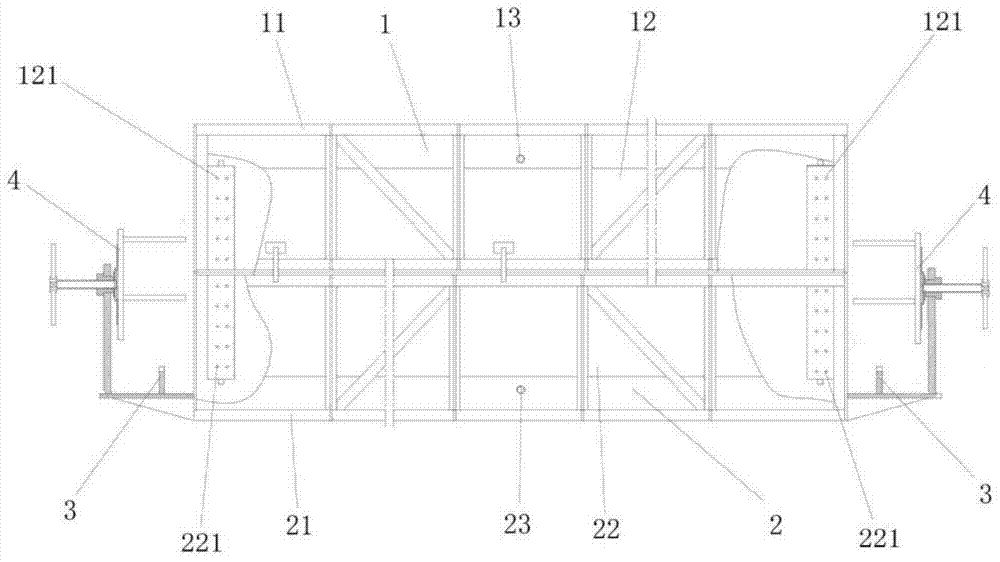

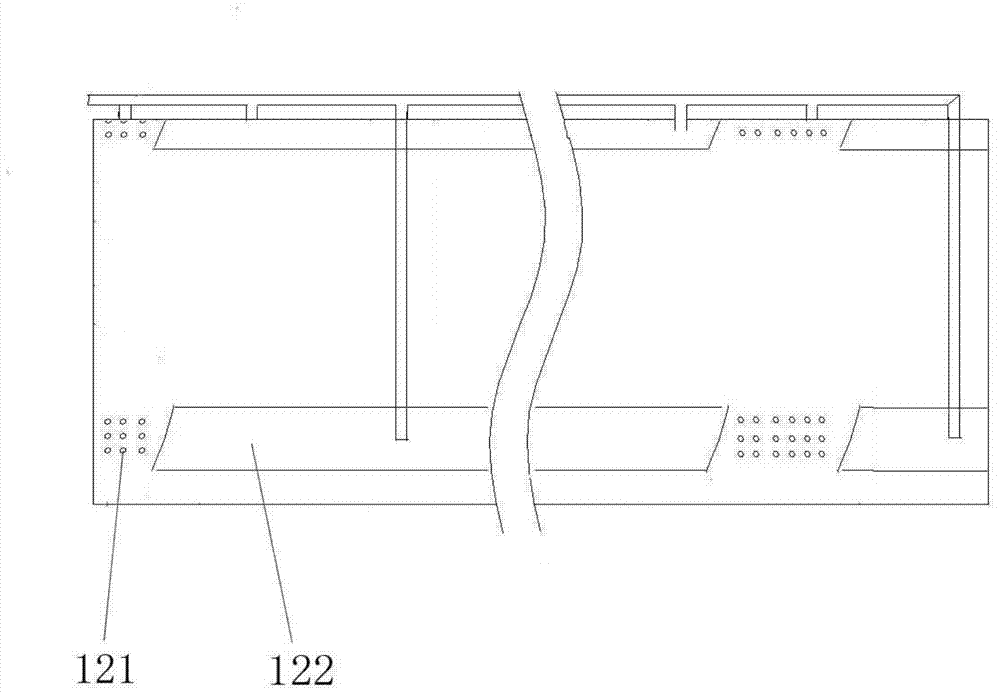

[0046] This embodiment provides a molding die for the insulation layer of the heat-insulating pipeline, such as figure 1 As shown, a mold body is included, and the mold body includes an upper mold 1 and a lower mold 2, and the upper mold 1 and the lower mold 2 form a split mold, and the upper mold 1 and the lower mold 2 respectively have a mold shell 11, 21 and mold liners 12, 22 with semi-cylindrical cavities installed inside corresponding to the mold shells 11, 21; several through holes 121, 221 are formed on the inner walls of the mold liners 12, 22 The outer walls of the mold liners 12, 22 are provided with cavities 122, 222 communicating with the through holes 121, 221, and the mold shells 11, 21 are formed with at least one The through-holes 121, 221 communicate with the air suction ports 13, 23, and the air suction ports 13, 23 are connected with the external vacuum assembly of the mould.

[0047] When using the forming mold of the thermal insulation layer of the heat-...

Embodiment 2

[0058] This embodiment provides a molding die for the heat insulation layer of a heat-insulating pipeline, which is a deformation on the basis of Embodiment 1. In this embodiment, the upper die 1 and the lower die 2 are composed of several sub-mold segments in the axial direction The through holes 121, 221, the air suction ports 13, 23 are arranged on the mold liners 12, 22 of each sub-mould section, and the through holes 14, 24 and The chambers 122 , 222 of the suction ports 13 , 23 .

[0059] By dividing the entire mold into multiple sub-sections, on the one hand, transportation and movement can be facilitated; on the other hand, by increasing or reducing the number of sub-sections, the heat-insulating pipe forming die of the present invention can manufacture heat-insulating pipes with different length requirements. In order not to affect the air pumping work of the vacuum pumping assembly, the through holes 121, 221, the air pumping ports 13, 23 are arranged on the mold lin...

Embodiment 3

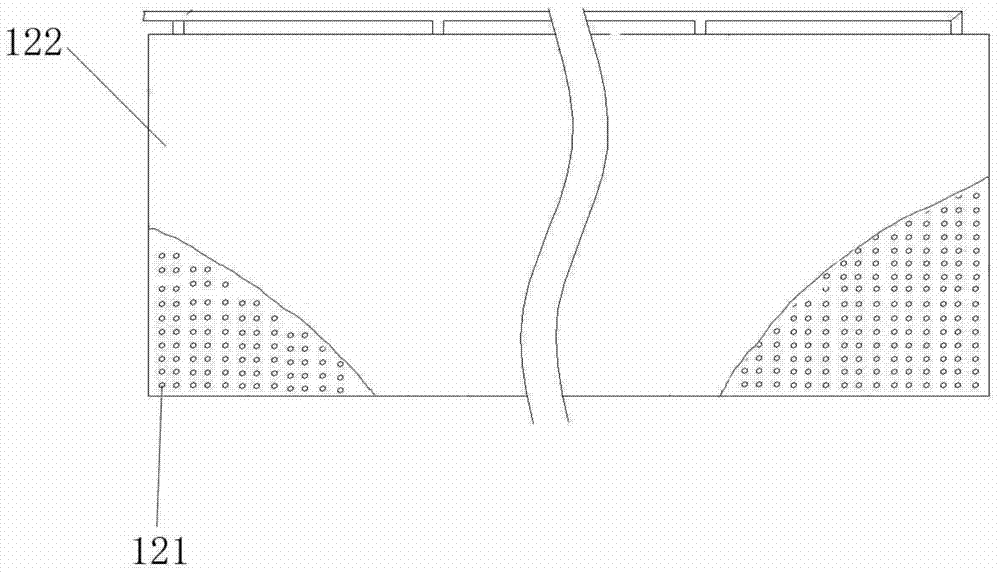

[0064] This embodiment provides a molding die for the heat insulation layer of a heat-insulating pipeline, which is a deformation based on Embodiment 2. In this embodiment, the mold liners 12 and 22 of each sub-die section There are several through-hole forming parts equidistantly arranged along the circumferential direction, and the through-holes 121, 221 are evenly distributed on each of the through-hole forming parts along the axial direction.

[0065] The through-holes 121, 221 are arranged in the form of through-hole 121, 221 forming parts along the circumferential direction, the through-holes 121, 221 are collectively arranged in the through-hole forming parts, and the through-hole forming parts are equidistantly arranged along the circumferential direction, and the upper The structure of the mold liner 121, 221 of the mold 1 and the lower mold 2 is exactly the same, here is the mold liner 121 of the upper mold 1 as an example, as Figure 4 As shown, thereby can ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com