Steel-structure double-layer glass curtain wall

A double-layer glass and steel structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of building insulation, easy deformation of supporting parts, and unreasonable structural design, so as to prolong the service life and strengthen the structure Intensity, air quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

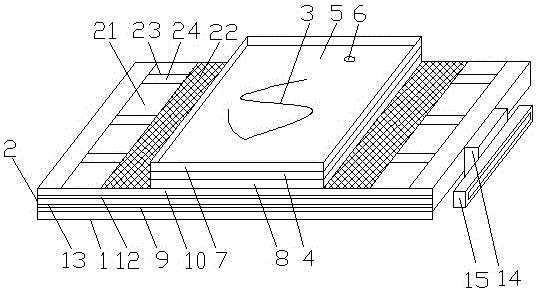

[0029] see figure 1 , a steel structure double-glazed curtain wall, including a steel frame frame 1 and a glass wall panel 2, and also includes a solar vacuum heat collector, and the solar vacuum heat collector is composed of a heat exchange tube 3, an aluminum heat absorbing plate 4 and a glass box body 5, the heat exchange tube 3 is embedded on the aluminum heat absorbing plate 4, the glass box body 5 is provided with an air extraction hole 6, the aluminum heat absorbing plate 4 is clamped in the glass box body 5, and the glass box body The first vacuum interlayer 7 and the second vacuum interlayer 8 are formed in the body 5, the first clamping layer 9 and the second clamping layer 10 are overlapped and embedded in the steel frame frame 1, and the glass wall panel 2 is located in the first clamping layer. Between the holding layer 9 and the second holding layer 10, the glass box body 5 is bonded on the surface of the second holding layer 10, and one side of the steel frame f...

Embodiment 2

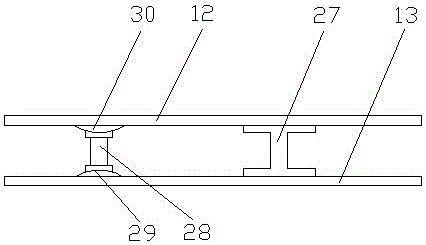

[0032] see figure 1 and figure 2 , a steel structure double-glazed curtain wall, including a steel frame frame 1 and a glass wall panel 2, and also includes a solar vacuum heat collector, and the solar vacuum heat collector is composed of a heat exchange tube 3, an aluminum heat absorbing plate 4 and a glass box body 5, the heat exchange tube 3 is embedded on the aluminum heat absorbing plate 4, the glass box body 5 is provided with an air extraction hole 6, the aluminum heat absorbing plate 4 is clamped in the glass box body 5, and the glass box body The first vacuum interlayer 7 and the second vacuum interlayer 8 are formed in the body 5, the first clamping layer 9 and the second clamping layer 10 are overlapped and embedded in the steel frame frame 1, and the glass wall panel 2 is located in the first clamping layer. Between the holding layer 9 and the second holding layer 10, the glass box body 5 is bonded on the surface of the second holding layer 10, and one side of th...

Embodiment 3

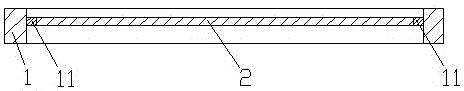

[0036] see figure 2 and image 3 , a steel structure double-glazed curtain wall, including a steel frame frame 1 and a glass wall panel 2, and also includes a solar vacuum heat collector, and the solar vacuum heat collector is composed of a heat exchange tube 3, an aluminum heat absorbing plate 4 and a glass box body 5, the heat exchange tube 3 is embedded on the aluminum heat absorbing plate 4, the glass box body 5 is provided with an air extraction hole 6, the aluminum heat absorbing plate 4 is clamped in the glass box body 5, and the glass box body The first vacuum interlayer 7 and the second vacuum interlayer 8 are formed in the body 5, the first clamping layer 9 and the second clamping layer 10 are overlapped and embedded in the steel frame frame 1, and the glass wall panel 2 is located in the first clamping layer. Between the holding layer 9 and the second holding layer 10, the glass box body 5 is bonded on the surface of the second holding layer 10, and one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com