Vacuum adsorption adapter gasket

A technology of vacuum adsorption and transfer pads, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of inability to quickly perform center positioning, reduce the overall workpiece processing efficiency, and the center of the wafer cannot be calibrated and pumped, so as to improve maintenance Speed, prevention of wafer damage, effects of slowing down slip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Figure 1 to Figure 6 shown:

[0027] The invention provides a vacuum adsorption transfer gasket,

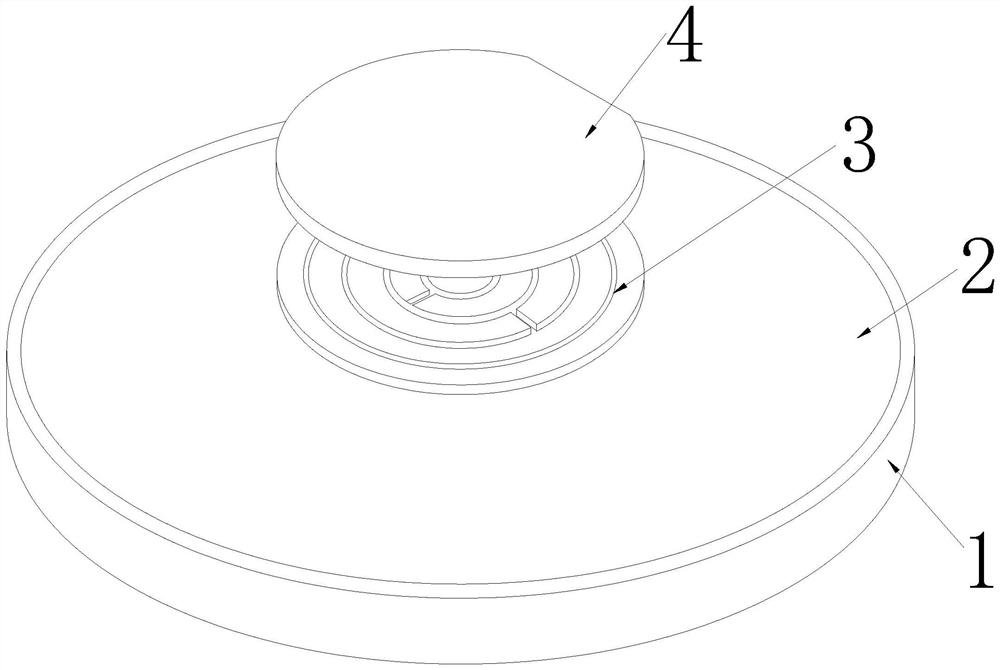

[0028] Its structure includes a main body 1, a vacuum suction cup 2, an adapter pad 3, and a wafer 4. The main body 1 and the vacuum suction cup 2 are an integrated structure, and the adapter gasket 3 is installed on the upper end of the vacuum suction cup 2. The wafer 4 is disposed above the transfer pad 3 and is adsorbed with the vacuum chuck 2 .

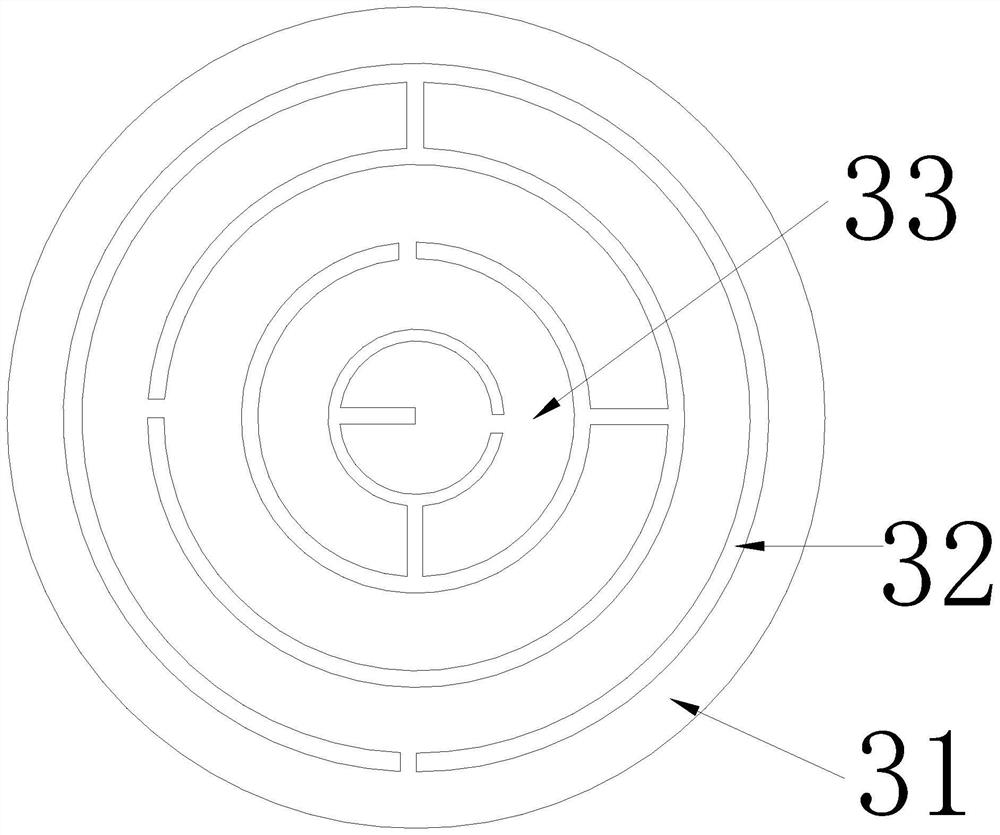

[0029] The adapter gasket 3 is provided with an outer layer 31 , an adsorption gap 32 and an inner ring 33 . The inner side of the outer layer 31 is integrated with the adsorption gap 32 for clearance fit, and the inner ring 33 is arranged on the inner side of the adsorption gap 32 . The outer layer 31 has a circular shape, and is provided with a plurality of adsorption gaps 32 inside. The adsorption gaps 32 are in a transparent state. The outer layer 31 can match the shape of the workpiece through its own shape. The adsor...

Embodiment 2

[0037] Figure 7 to Figure 8 shown:

[0038] The invention provides a vacuum adsorption transfer gasket,

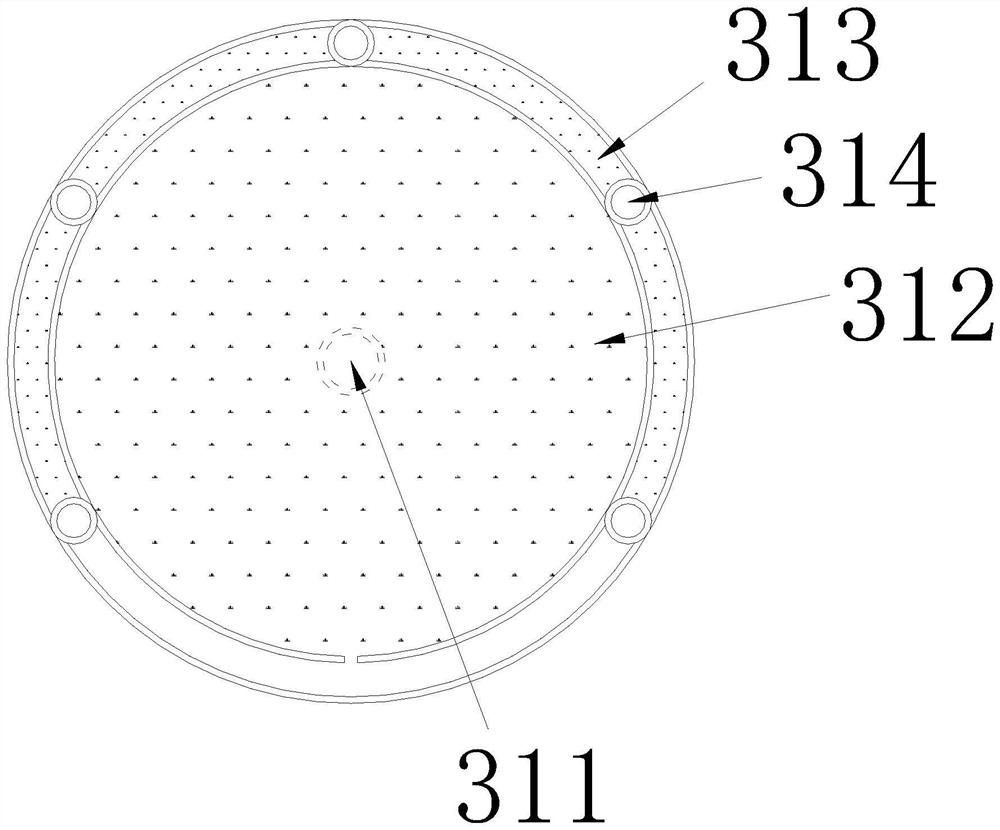

[0039] Its structure includes that the auxiliary software 313 is provided with a watch case c1, a connecting grid c2, a clamping block c3, a pressing shaft c4, and a rubber body c5, the side end of the watch case c1 is integrated with the connecting grid c2, and the clamping block c3 is embedded. At the center of the connection grid c2, the pressing shaft c4 is connected with the center of the clamping block c3, and the rubber body c5 is pressed together with the pressing shaft c4. The pressing shaft c4 is made of stainless steel, and its surface layer is Polishing effect, at the same time, the connecting grid c2 is a semicircle shape, the pressing shaft c4 can effectively prolong its own service cycle through its own stainless steel material, and the polishing effect of the surface layer can prevent the internal rubber body c5 from being scratched and damaged when it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com